The unique properties of PTFE that make it highly suitable for CNC machining are its exceptional chemical inertness, wide thermal stability, and an extremely low coefficient of friction. These characteristics make it a go-to material for parts that must operate in harsh environments or require smooth, non-stick surfaces, such as seals, bearings, and electrical insulators.

While PTFE's core properties make it incredibly valuable for finished components, its inherent softness and tendency to expand with heat present unique challenges. Successful machining depends entirely on understanding and managing these material behaviors.

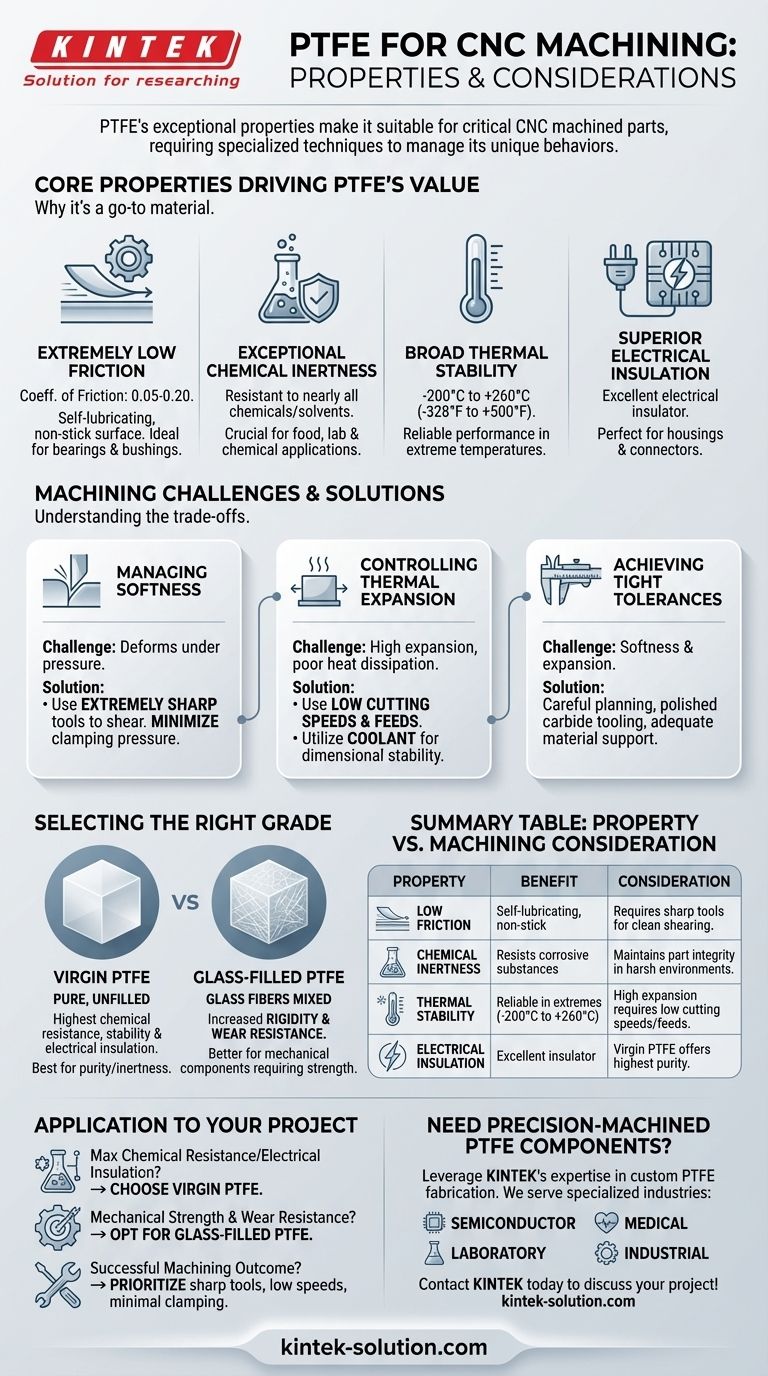

The Core Properties Driving PTFE's Value

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is a fluoropolymer with a distinct combination of traits that make it a frequent choice for machined parts in demanding applications.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, typically between 0.05 and 0.20.

This creates a self-lubricating, non-stick surface ideal for components like bearings and bushings where smooth movement and low wear are critical.

Exceptional Chemical Inertness

This material is highly resistant to nearly all chemicals and solvents.

This property makes it indispensable for components used in food processing, laboratory instrumentation, and chemical manufacturing where exposure to corrosive substances is constant.

Broad Thermal Stability

PTFE maintains its integrity across an exceptionally wide range of temperatures, from -200°C to +260°C (-328°F to +500°F).

This allows machined PTFE parts to perform reliably in applications involving extreme cold or high heat without degrading.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, making it a perfect material for manufacturing electrical housings, connectors, and other components where blocking electrical current is necessary.

Understanding the Trade-offs: Machining Challenges

The very properties that make PTFE desirable also introduce specific challenges during the CNC machining process. An operator's success hinges on mitigating these factors.

Managing Material Softness

PTFE is a soft material that can easily deform under pressure.

This requires using extremely sharp tools to shear the material cleanly rather than push it. It also means clamping pressure must be minimized to avoid distorting the workpiece during machining.

Controlling Thermal Expansion

The material has a high rate of thermal expansion and does not dissipate heat well.

Friction from cutting tools can generate heat, causing the part to expand and throwing off final dimensions. This necessitates using low cutting speeds and feeds and often requires coolant to maintain dimensional stability.

Achieving Tight Tolerances

The combination of softness and thermal expansion makes holding tight tolerances a significant challenge.

Success requires careful planning, appropriate tooling (such as polished carbide tools), and providing adequate support for the material to prevent tool chatter or vibration.

Selecting the Right Grade of PTFE

Not all PTFE is the same. The grade you choose directly impacts the final part's performance characteristics.

Virgin PTFE

This is pure, unfilled PTFE. It offers the highest chemical resistance, stability, and electrical insulation properties.

It is the ideal choice when purity and inertness are the primary requirements for the application.

Glass-Filled PTFE

This grade includes glass fibers mixed into the PTFE resin.

The glass provides increased rigidity and wear resistance, making it better suited for mechanical components that require higher strength and durability than virgin PTFE can offer.

How to Apply This to Your Project

Your specific goal will determine which material properties and machining considerations are most important.

- If your primary focus is maximum chemical resistance or electrical insulation: Choose virgin PTFE for its purity and superior inertness.

- If your primary focus is mechanical strength and wear resistance: Opt for glass-filled PTFE to gain the necessary rigidity and durability for your component.

- If your primary focus is achieving a successful machining outcome: Prioritize using exceptionally sharp tools, low cutting speeds, and minimal clamping force to manage the material's softness and thermal expansion.

Ultimately, mastering PTFE machining is about adapting your process to respect the material's unique combination of strengths and sensitivities.

Summary Table:

| Property | Benefit for Machined Parts | Key Consideration for Machining |

|---|---|---|

| Low Friction (0.05-0.20) | Self-lubricating, non-stick surfaces for bearings, seals. | Minimizes wear but requires sharp tools for clean shearing. |

| Chemical Inertness | Resists corrosive substances; ideal for labs, chemical processing. | Maintains part integrity in harsh environments. |

| Thermal Stability (-200°C to +260°C) | Reliable performance in extreme temperatures. | High thermal expansion requires low cutting speeds/feeds. |

| Electrical Insulation | Excellent for electrical housings and connectors. | Virgin PTFE offers the highest purity for critical applications. |

Need Precision-Machined PTFE Components?

Leverage KINTEK's expertise in custom PTFE fabrication. We understand the unique challenges of machining PTFE and its variants, like glass-filled grades for enhanced strength. Our precision production ensures your components—from seals and liners to complex labware—meet exact specifications, from prototypes to high-volume orders.

We serve specialized industries where material performance is critical:

- Semiconductor

- Medical

- Laboratory

- Industrial

Contact KINTEB today to discuss your project and get a quote for reliable, high-performance PTFE parts!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support