To put it simply, 5-axis CNC machining is the preferred method for complex Teflon parts because it provides the necessary precision and flexibility to overcome the material's uniquely challenging properties. Its ability to machine intricate geometries in a single setup minimizes part handling, which is critical for a soft, thermally sensitive material like Teflon that is prone to deformation and burrs.

Teflon's core challenge is that its desirable properties—softness, low friction, and chemical inertness—make it notoriously difficult to machine accurately. 5-axis machining directly counters these difficulties by enabling superior tool control, reducing setup errors, and achieving a higher quality finish from the start.

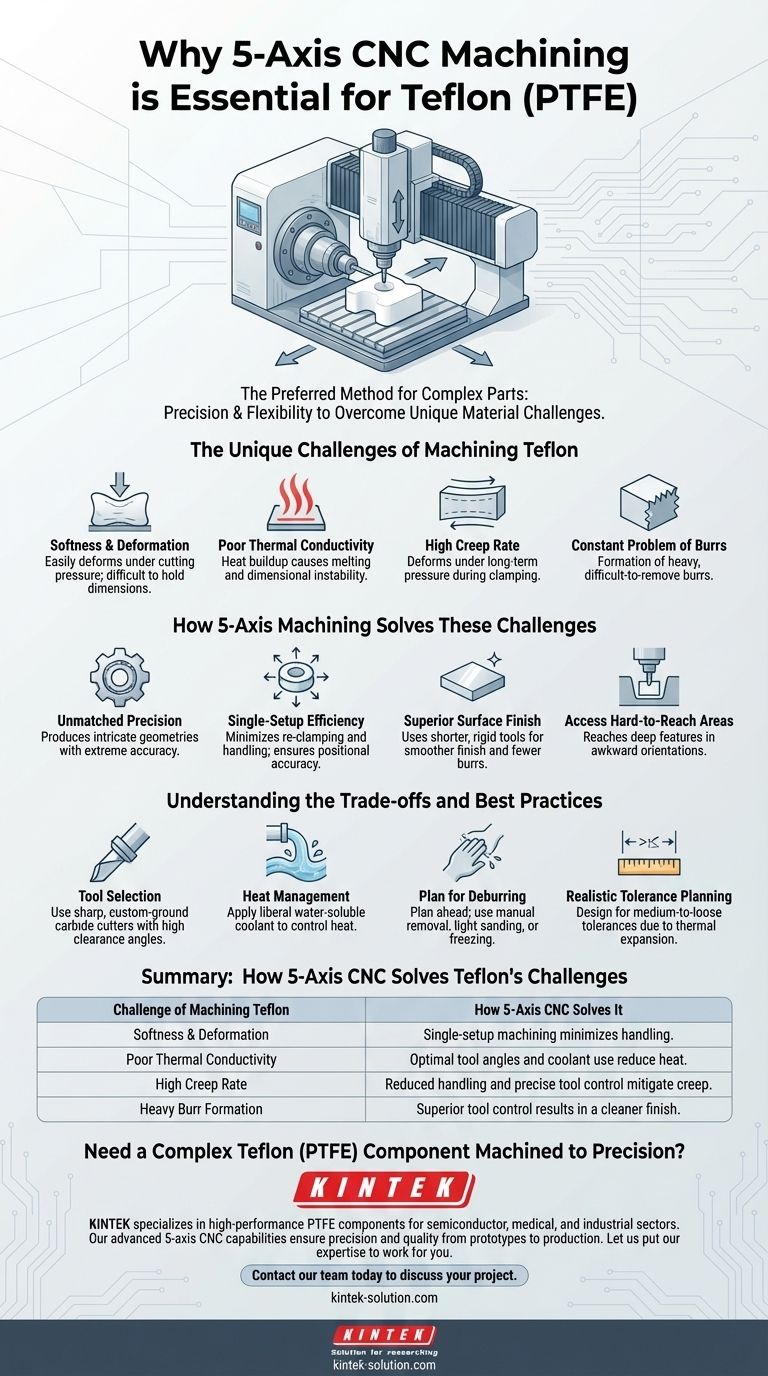

The Unique Challenges of Machining Teflon

Before understanding the solution, we must first appreciate the problem. Teflon, or Polytetrafluoroethylene (PTFE), presents several distinct obstacles during the machining process that simpler methods struggle to overcome.

Softness and Deformation

Teflon is exceptionally soft and flexible. This means it can easily deform or compress under the pressure of a cutting tool, making it difficult to hold dimensions accurately.

Poor Thermal Conductivity

The material does not dissipate heat well. The friction from the cutting process can quickly cause localized heat buildup, which can lead to melting, smearing, and dimensional instability due to Teflon's high coefficient of thermal expansion.

High Creep Rate

Teflon has a tendency to "creep," or slowly deform, when subjected to long-term pressure. This can be an issue both when clamping the workpiece and during the cutting process itself.

The Constant Problem of Burrs

One of the most significant issues with machining Teflon is the formation of heavy burrs—thin ridges of unwanted material left on the edges of the part. These are difficult to remove without damaging the component's surface.

How 5-Axis Machining Solves These Challenges

A 5-axis CNC machine can move a part or a tool on five different axes simultaneously. This sophisticated capability directly addresses Teflon's inherent weaknesses.

Unmatched Precision for Complex Designs

The primary advantage is the ability to produce highly complex geometries with extreme accuracy. The machine can orient the tool at any angle, allowing for the creation of intricate contours and deep pockets that would be impossible with fewer axes.

Single-Setup Efficiency

Perhaps most critically for Teflon, 5-axis machines can approach a workpiece from virtually all sides in a single setup. This drastically reduces the need to re-clamp the part, minimizing the risk of deformation from handling and ensuring higher positional accuracy across all features.

Superior Surface Finish

By optimizing the tool's cutting angle relative to the part's surface, a 5-axis machine can use shorter, more rigid cutting tools. This reduces tool vibration, minimizes heat generation, and results in a much smoother surface finish with fewer burrs.

Access to Hard-to-Reach Areas

The machine's agility allows it to access features deep within a part or in awkward orientations, ensuring every detail of a complex design is machined correctly without compromise.

Understanding the Trade-offs and Best Practices

While 5-axis machining is a powerful solution, success is not automatic. Achieving high-quality results with Teflon requires a specific approach and awareness of potential pitfalls.

Tool Selection is Non-Negotiable

Standard tools are inadequate. You must use extremely sharp cutting tools, often custom-ground carbide cutters, designed with high clearance angles to prevent rubbing and cleanly shear the material rather than pushing it.

Effective Heat Management

Controlling heat is paramount. This involves applying liberal amounts of a water-soluble coolant to continuously wash away heat and chips from the cutting zone.

Plan for Deburring

Even with the best process, some burrs are likely. A deburring strategy must be planned in advance. Common methods include careful manual removal, light sanding, or even freezing the part to make the burrs brittle and easier to snap off.

Realistic Tolerance Planning

Due to Teflon's high rate of thermal expansion and its tendency to creep, holding extremely tight tolerances is a significant challenge. It's often best to design for medium-to-loose tolerances wherever possible to ensure manufacturability.

Making the Right Choice for Your Teflon Part

Selecting the right manufacturing process depends entirely on the complexity and requirements of your specific component.

- If your primary focus is complex geometries and high precision: 5-axis CNC machining is the definitive and often only choice to achieve the design intent without compromise.

- If your primary focus is cost-effectiveness for simple parts: For components like basic washers or blocks with looser tolerances, a simpler 3-axis CNC machine or CNC turning may be sufficient.

- If your primary focus is minimizing post-processing: The superior surface finish from a 5-axis machine will significantly reduce the time and cost associated with manual deburring and finishing.

Ultimately, choosing 5-axis machining for Teflon is an investment in control, allowing you to master a difficult material and produce a superior final part.

Summary Table:

| Challenge of Machining Teflon | How 5-Axis CNC Solves It |

|---|---|

| Softness & Deformation | Single-setup machining minimizes handling and clamping pressure. |

| Poor Thermal Conductivity | Optimal tool angles and coolant use reduce heat buildup. |

| High Creep Rate | Reduced part handling and precise tool control mitigate creep. |

| Heavy Burr Formation | Superior tool control and cutting angles result in a cleaner finish. |

Need a Complex Teflon (PTFE) Component Machined to Precision?

At KINTEK, we specialize in manufacturing high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our advanced 5-axis CNC machining capabilities are specifically tailored to handle Teflon's unique challenges, ensuring your parts meet the highest standards for precision and quality—from custom prototypes to high-volume production runs.

Let us put our expertise to work for you. Contact our team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications