At its core, the primary advantage of using PTFE lip seals in high-speed rotary applications is their exceptionally low coefficient of friction. This single property directly translates into significantly less heat generation, reduced power consumption, and minimal wear, allowing machinery to operate at higher speeds for longer periods without premature seal failure.

The fundamental challenge in high-speed sealing is managing friction-induced heat. PTFE's inherent lubricity breaks the cycle of friction, heat, and wear that causes traditional elastomer seals to fail, making it the superior choice for demanding, high-velocity applications.

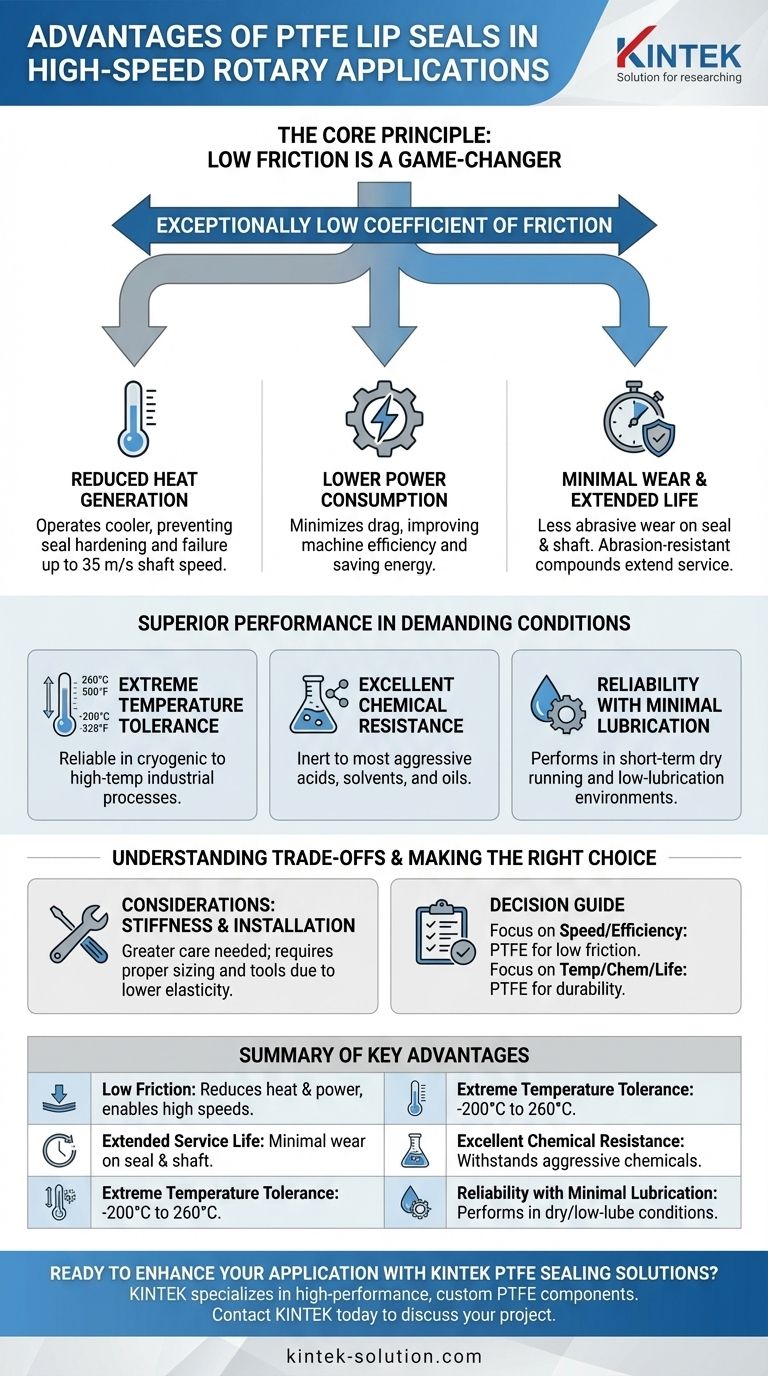

The Core Principle: Why Low Friction is a Game-Changer for Speed

In any rotary system, friction between the seal lip and the rotating shaft is the enemy of speed and longevity. As rotational velocity increases, this friction generates heat, which can degrade lubricants, harden the seal material, and ultimately lead to system failure. PTFE's unique molecular structure gives it one of the lowest friction coefficients of any solid material.

Reduced Heat Generation

At high rotational speeds, conventional seals can generate enough heat to compromise their own integrity.

PTFE seals run significantly cooler, allowing them to maintain their sealing performance and material properties at shaft surface speeds up to 35 m/s. This prevents the seal lip from hardening, cracking, or losing contact with the shaft.

Lower Power Consumption

Friction is a direct source of energy loss. By minimizing this drag, PTFE seals reduce the amount of power required to turn the shaft.

This leads to improved overall machine efficiency and can result in tangible energy savings over the equipment's operational life.

Minimal Wear and Extended Service Life

Less friction means less abrasive wear on both the seal lip and the shaft surface. This dual benefit is critical for long-term reliability.

The use of abrasion-resistant compounds in PTFE seals further extends their service life, reducing downtime and maintenance costs. They can even eliminate the shaft wear sometimes caused by other bushing materials.

Superior Performance in Demanding Conditions

High-speed applications rarely exist in a vacuum. They are often accompanied by other environmental challenges, which is where PTFE's versatility provides further advantages.

Extreme Temperature Tolerance

PTFE seals are capable of operating reliably across an exceptionally wide temperature range, typically from -200°C (-328°F) to 260°C (500°F).

This makes them suitable for applications involving cryogenic fluids or high-temperature industrial processes where standard elastomers would become brittle or degrade.

Excellent Chemical Resistance

PTFE is virtually inert to most industrial chemicals, including aggressive acids, solvents, bases, and oils.

This chemical compatibility ensures the seal maintains its integrity in corrosive environments that would quickly destroy conventional seal materials.

Reliability with Minimal Lubrication

A key advantage of PTFE is its ability to perform reliably even in poorly lubricated conditions.

These seals can withstand short-term dry running and extended operation in low-lubrication environments, providing a crucial safety margin where lubricant starvation is a risk.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. Understanding their characteristics is key to successful implementation.

Elasticity and Installation

Compared to traditional rubber elastomers, PTFE is a much stiffer material. It has less "memory" and elasticity.

This means installation requires greater care to avoid damaging the seal lip. Proper sizing and the use of correct installation tools are critical for achieving a reliable seal.

Conformability to Shaft Imperfections

The relative stiffness of PTFE means it is less forgiving of imperfections in the shaft surface finish or geometry.

For optimal performance, PTFE seals require a smooth, high-quality shaft surface to ensure a consistent and leak-free dynamic seal.

Making the Right Choice for Your Application

Selecting the right seal requires aligning its properties with your primary operational goal.

- If your primary focus is maximum rotational speed and efficiency: PTFE is the clear choice due to its low friction, which directly minimizes heat buildup and power loss.

- If your primary focus is reliability in extreme temperatures or chemical environments: The vast operating temperature range and chemical inertness of PTFE offer unmatched performance where other materials would fail.

- If your primary focus is extending maintenance intervals and equipment life: The combination of low wear on both the seal and the shaft makes PTFE a strategic investment in long-term reliability and reduced downtime.

Ultimately, PTFE lip seals provide a definitive engineering solution for applications where speed, temperature, and chemical exposure push beyond the limits of conventional materials.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Low Friction | Reduces heat generation & power consumption, enables speeds up to 35 m/s |

| Extended Service Life | Minimal wear on seal and shaft, reducing downtime |

| Extreme Temperature Tolerance | Operates from -200°C to 260°C |

| Excellent Chemical Resistance | Withstands aggressive acids, solvents, and oils |

| Reliability with Minimal Lubrication | Performs in low-lubrication or dry-running conditions |

Ready to enhance your high-speed application with superior PTFE sealing solutions?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure you get a seal engineered for your specific speed, temperature, and chemical requirements.

Contact KINTEK today to discuss your project and discover how our PTFE expertise can boost your equipment's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications