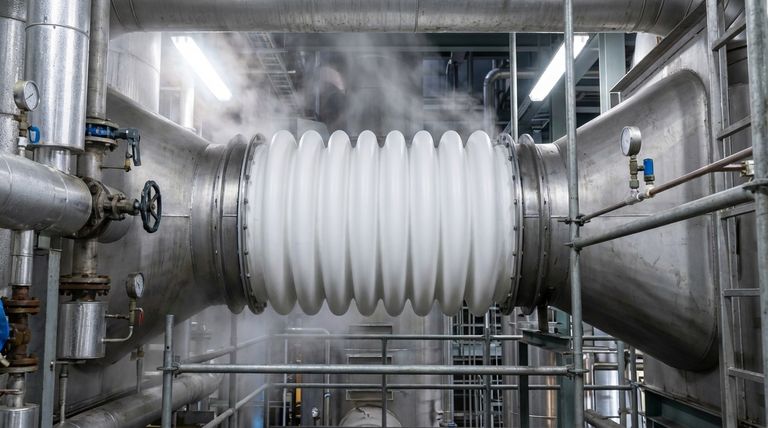

At its core, a PTFE expansion bellow is a specialized flexible connector used in pollution control systems to safely contain and transport harmful substances. It acts as a durable, chemically inert bridge in piping or ductwork, absorbing system movements like thermal expansion and vibration while preventing the escape of corrosive gases or liquids. This ensures the integrity and safety of the entire emission control process.

The essential contribution of PTFE expansion bellows is their unique ability to combine extreme chemical resistance with mechanical flexibility. This pairing allows them to solve critical sealing and movement challenges in harsh environments where rigid components or less durable materials would quickly fail.

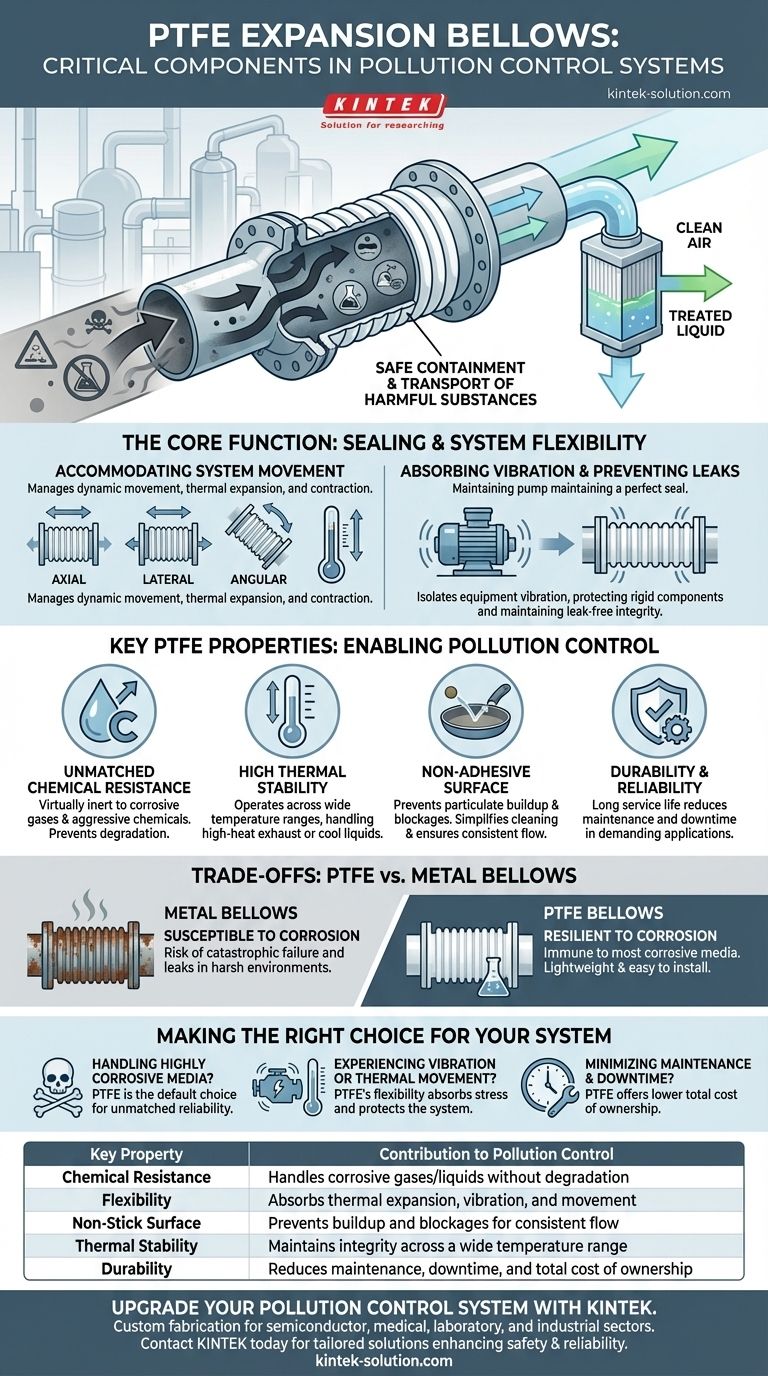

The Core Function: Sealing and System Flexibility

In any industrial piping or ducting system, movement is inevitable. PTFE expansion bellows are engineered specifically to manage this dynamic reality, particularly in the demanding context of pollution control.

Accommodating System Movement

PTFE bellows are highly flexible, capable of compensating for axial (compression/extension), lateral (sideways), and angular movements. This is critical for accommodating the thermal expansion and contraction of pipework as process temperatures fluctuate.

Absorbing Vibration

Industrial equipment, such as pumps and scrubbers, generates significant vibration. A PTFE expansion bellow isolates this vibration, preventing it from transferring through the system, which could damage rigid components and compromise seals.

Preventing Leaks of Harmful Media

By seamlessly handling these movements, the bellow maintains a perfect seal. This containment is the primary goal of any pollution control system, ensuring that hazardous materials are safely transported for treatment or disposal.

Key Properties That Enable Pollution Control

The effectiveness of PTFE bellows stems directly from the inherent properties of the Polytetrafluoroethylene material itself.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and corrosive gases. This makes it the ideal material for handling the aggressive substances often found in industrial exhaust streams, preventing degradation and system failure.

High Thermal Stability

These bellows can operate across a wide range of temperatures. This tolerance ensures they maintain their structural integrity and flexibility whether the system is handling high-temperature exhaust or cooled liquids.

Non-Adhesive Surface

PTFE has a non-stick surface, which prevents particulates or viscous substances from building up inside the bellow. This prevents blockages, simplifies cleaning, and ensures consistent flow through the system.

Durability and Reliability

Engineered for demanding applications, PTFE bellows enhance overall system reliability and safety. Their long service life reduces the need for frequent maintenance, minimizing downtime and associated costs.

Understanding the Trade-offs vs. Metal Bellows

While metal expansion joints exist, PTFE offers clear advantages in the specific context of pollution control.

The Corrosion Problem

The primary weakness of metal bellows is their susceptibility to corrosion. In environments with acidic gases, saline water, or other harsh chemicals, metal will rust and degrade, leading to catastrophic failure and leaks.

The Resilience of PTFE

PTFE, by contrast, is completely unaffected by the vast majority of corrosive media. This inherent immunity makes it a far more reliable and long-lasting choice for chemical processing and pollution management applications.

Lightweight and Simplified Installation

PTFE bellows are significantly lighter than their metal counterparts. This makes them easier and safer to handle and install, often requiring less labor and no specialized heavy equipment, which contributes to lower initial costs.

Making the Right Choice for Your System

Selecting the right component is critical for ensuring both regulatory compliance and operational safety.

- If your primary focus is handling highly corrosive media: PTFE is the default choice, as its chemical inertness provides unmatched reliability where metal would quickly fail.

- If your system experiences significant vibration or thermal movement: The superior flexibility of PTFE bellows is essential for absorbing these stresses and protecting the integrity of the entire system.

- If your goal is to minimize long-term maintenance and downtime: The durability and corrosion resistance of PTFE lead to a lower total cost of ownership compared to materials that require frequent inspection and replacement.

By leveraging the unique material science of PTFE, engineers can build more resilient, reliable, and compliant pollution control systems.

Summary Table:

| Key Property | Contribution to Pollution Control |

|---|---|

| Chemical Resistance | Handles corrosive gases/liquids without degradation |

| Flexibility | Absorbs thermal expansion, vibration, and movement |

| Non-Stick Surface | Prevents buildup and blockages for consistent flow |

| Thermal Stability | Maintains integrity across a wide temperature range |

| Durability | Reduces maintenance, downtime, and total cost of ownership |

Upgrade your pollution control system with precision-engineered PTFE components from KINTEK.

Our PTFE expansion bellows are specifically designed to solve critical sealing and movement challenges in the harshest environments, ensuring your system remains leak-free, compliant, and operational. We specialize in custom fabrication—from prototypes to high-volume orders—for the semiconductor, medical, laboratory, and industrial sectors.

Contact KINTEK today to discuss your specific requirements and receive a tailored solution that enhances safety and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions