Beyond the expected chemical and pharmaceutical plants, PTFE bellows are critical components in a surprising range of demanding fields. Their use extends into industries like semiconductor manufacturing for ultra-pure environments, steel mills and foundries for extreme heat resistance, and complex automotive systems for reliable, long-term sealing against harsh fluids.

The "unusual" applications for PTFE bellows are not random; they are a direct result of the material's unique ability to solve problems of sealing and flexibility where nearly every other material would fail. Understanding these uses is to understand the absolute limits of material science in purity, temperature, and chemical inertness.

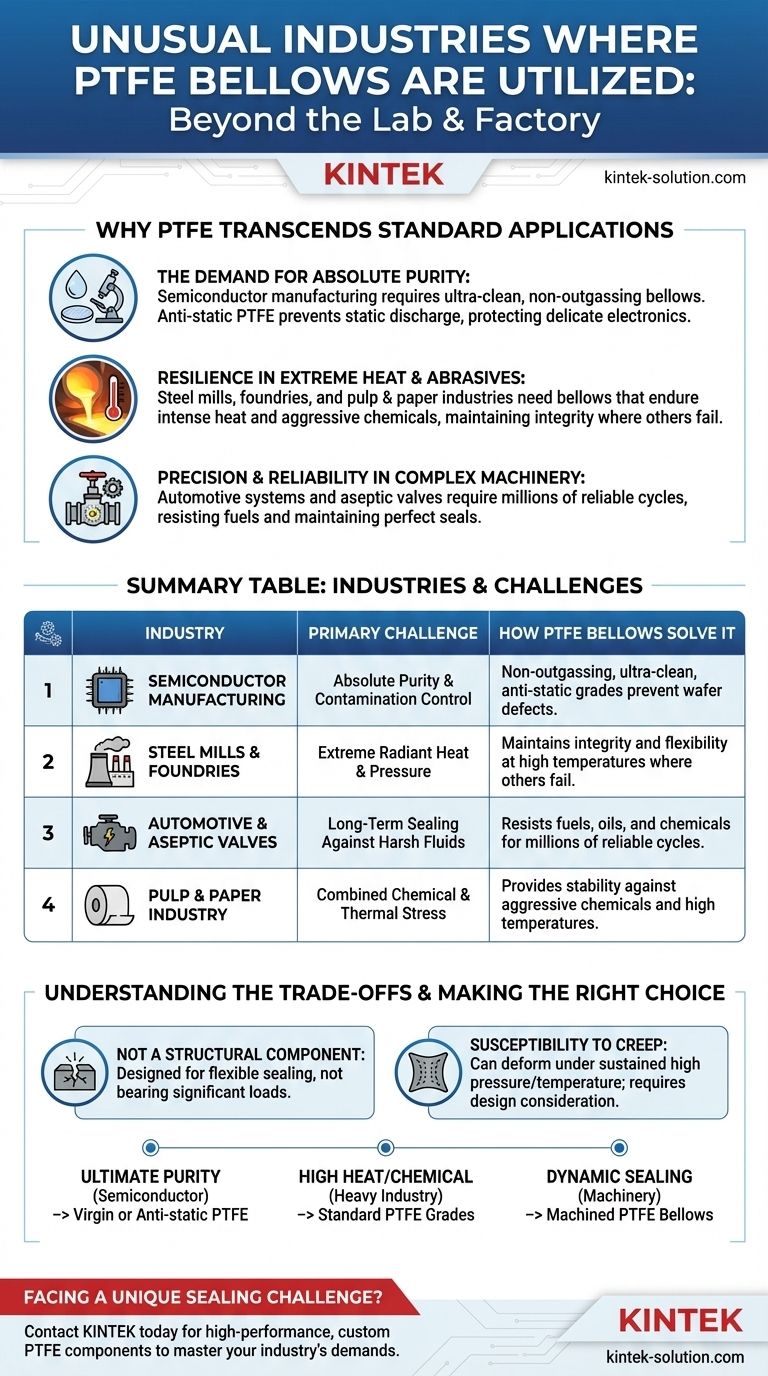

Why PTFE Bellows Transcend Standard Applications

The versatility of PTFE is not just about resisting one harsh condition, but about resisting several simultaneously. This unique combination of properties is what allows it to be the component of choice in fields far beyond the typical lab or factory floor.

The Demand for Absolute Purity

In some industries, the enemy is not a corrosive chemical but any foreign particle at all. This is where PTFE's inherent purity shines.

Semiconductor manufacturing is a prime example. The process of creating microchips is so sensitive that a single microscopic dust particle or the slightest outgassing from a component can ruin an entire batch of expensive wafers. PTFE bellows are used in vacuum systems and fluid handling because they are exceptionally clean and do not release contaminants.

Specialized anti-static PTFE is used here to prevent static electricity buildup. A static discharge can instantly destroy the delicate electronic circuitry being fabricated, making this material property non-negotiable.

Resilience in Extreme Heat and Abrasives

While many plastics melt or degrade, PTFE maintains its integrity at high temperatures, making it essential for heavy industry.

In steel mills and foundries, bellows must endure intense radiant heat and pressure fluctuations. PTFE provides a reliable flexible seal in hydraulic or pneumatic systems where a rubber or standard plastic component would quickly fail.

The pulp and paper industry also relies on PTFE bellows. The process involves both aggressive chemicals for breaking down wood fiber and high temperatures, creating an environment that demands both chemical resistance and thermal stability.

Precision and Reliability in Complex Machinery

In systems that require millions of cycles without failure, material stability is paramount.

Automotive systems use PTFE bellows in specific applications where they must resist degradation from fuels, oils, and coolants while providing a flexible seal. Their reliability ensures long-term performance in components like specialized valves.

Aseptic and solenoid valves require bellows that can move precisely while maintaining a perfect seal to prevent contamination or leaks. Machined PTFE bellows offer the tight tolerances and long cycle life necessary for this kind of precision equipment.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not a universal solution. Acknowledging its limitations is key to using it effectively.

Not a Structural Component

PTFE bellows are designed for flexible sealing and connection, not for bearing significant mechanical loads. They are meant to accommodate misalignment, vibration, or thermal expansion in a piping or ducting system, but they are not a replacement for structural metal supports.

Susceptibility to Creep

Like many polymers, PTFE can be subject to "creep" or cold flow. Under sustained high pressure and temperature, the material can slowly deform over time. This must be a consideration in the design phase for high-stress applications to ensure long-term sealing integrity.

The Cost-Benefit Calculation

PTFE is a premium, high-performance material, and its cost reflects that. It is often selected despite its price because the cost of failure—such as a contaminated semiconductor batch, a critical valve failure, or a hazardous chemical leak—is astronomically higher.

Making the Right Choice for Your Environment

Choosing the correct material comes down to identifying the most extreme challenge in your specific application.

- If your primary focus is ultimate purity: Virgin PTFE or specialized anti-static grades are essential for semiconductor, vacuum, or sensitive laboratory applications.

- If your primary focus is high heat and chemical exposure: Standard PTFE grades provide the robust performance needed in heavy industries like steel mills, foundries, or chemical processing.

- If your primary focus is dynamic sealing in machinery: Machined PTFE bellows offer the precision and long cycle life required for critical components like aseptic valves or automotive systems.

The right choice is dictated by identifying the single most demanding constraint in your system and selecting the material engineered to master it.

Summary Table:

| Industry | Primary Challenge | How PTFE Bellows Solve It |

|---|---|---|

| Semiconductor Manufacturing | Absolute Purity & Contamination Control | Non-outgassing, ultra-clean, anti-static grades prevent wafer defects. |

| Steel Mills & Foundries | Extreme Radiant Heat & Pressure | Maintains integrity and flexibility at high temperatures where others fail. |

| Automotive & Aseptic Valves | Long-Term Sealing Against Harsh Fluids | Resists fuels, oils, and chemicals for millions of reliable cycles. |

| Pulp & Paper Industry | Combined Chemical & Thermal Stress | Provides stability against aggressive chemicals and high temperatures. |

Facing a unique sealing challenge in a demanding environment?

KINTEK specializes in manufacturing high-performance PTFE components, including custom bellows, seals, and liners. Whether your application demands ultimate purity for semiconductor manufacturing, extreme heat resistance for heavy industry, or precision for complex machinery, our expertise in custom fabrication—from prototypes to high-volume orders—ensures a solution tailored to your most critical constraints.

Contact KINTEK today to discuss how our PTFE components can master the extreme demands of your industry.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What economic advantages do ePTFE gaskets offer? Lower Total Cost of Ownership

- Why are PTFE lined valves preferred globally? Achieve Superior Corrosion Resistance & Cost Savings

- What makes PTFE gaskets an ideal sealing material? Unmatched Chemical & Temperature Resistance

- What are the performance specifications of PTFE-lined bearings? Achieve Maintenance-Free, High-Load Performance

- How does a PTFE lined butterfly valve compare to other valve types? A Guide to Superior Sealing & Chemical Resistance

- What types of gasket materials are available besides PTFE? Find the Perfect Seal for Your Application

- Why are PTFE seals preferred in press machinery in the pharmaceutical industry? Ensuring Purity and Performance

- What factors have contributed to the expansion of the global supply chain for Teflon machined parts? Key Drivers and Industry Insights