At its core, Polytetrafluoroethylene (PTFE) is an ideal sealing material because it possesses a rare combination of extreme chemical inertness, a vast operational temperature range, and an exceptionally low coefficient of friction. Unlike other materials that might excel in one area but fail in another, PTFE delivers reliable performance across a wide spectrum of demanding industrial conditions.

The true value of PTFE is not any single property, but its unique ability to solve multiple sealing challenges simultaneously. It resists virtually all chemicals, functions in extreme cold and heat, and minimizes friction, making it the default choice for applications where other materials would quickly degrade or fail.

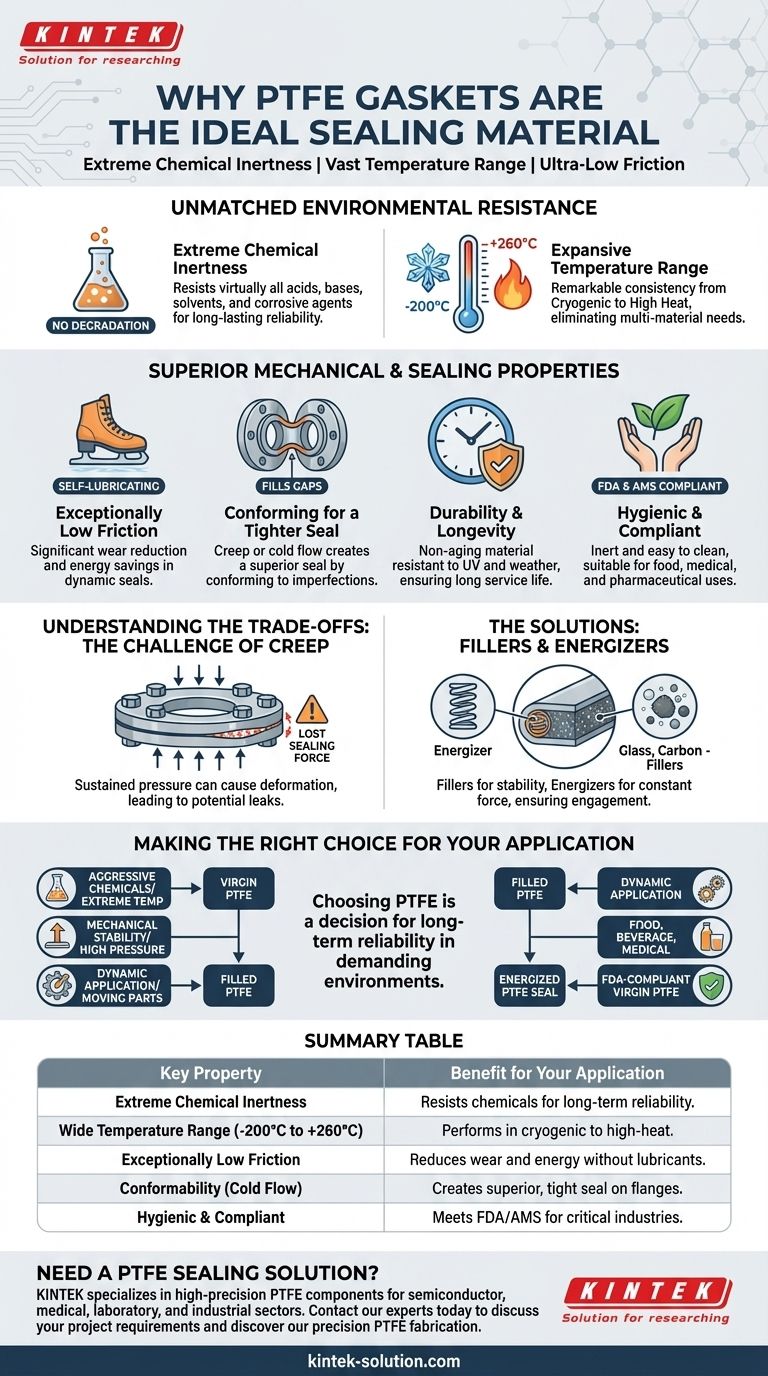

Unmatched Environmental Resistance

The primary function of a seal is to remain stable and effective in its operating environment. PTFE excels here due to two key properties that are difficult to find in a single material.

Extreme Chemical Inertness

PTFE is virtually immune to chemical attack. It resists degradation from the most aggressive acids, bases, solvents, and corrosive agents.

This means the gasket will not swell, soften, or break down over its service life, ensuring a reliable and long-lasting seal in chemical processing, pharmaceuticals, and other harsh environments.

Expansive Temperature Range

This material demonstrates remarkable consistency across a huge thermal window, typically from -200°C to +260°C (-328°F to +500°F).

It maintains its strength and flexibility in cryogenic applications and does not melt or deform at high temperatures. This versatility eliminates the need to source different materials for applications with fluctuating or extreme temperature requirements.

Superior Mechanical and Sealing Properties

Beyond simple resistance, a gasket must create and maintain a physical barrier. PTFE's mechanical characteristics are uniquely suited for this task.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, a property often compared to wet ice on wet ice. This is known as self-lubrication.

For dynamic seals with moving parts, this means significantly less wear, lower energy consumption, and smoother operation without the need for external lubricants.

Conforming for a Tighter Seal

A critical feature of PTFE is its tendency for "creep" or "cold flow." Unlike materials with strong "memory" that return to their original shape, PTFE will slowly conform to the imperfections of a mating flange or surface.

This allows it to fill in microscopic gaps, creating an extremely tight and secure seal that is difficult to achieve with more rigid materials.

Durability and Longevity

PTFE is a "non-aging" material. It does not degrade from exposure to UV light or weather, and its inherent properties remain stable over very long periods.

This translates directly to a longer service life, reduced maintenance cycles, and greater operational reliability.

Hygienic and Compliant

Because it is inert and non-absorbent, PTFE is easy to clean and does not support bacterial growth.

It often conforms to FDA and AMS requirements, making it an ideal and trusted choice for gaskets in food production, medical devices, and pharmaceutical manufacturing.

Understanding the Trade-offs: The Challenge of Creep

While PTFE's ability to "creep" is a benefit for creating an initial tight seal, it is also its primary engineering challenge.

The Problem of Lost Sealing Force

Under sustained pressure and temperature, the same cold flow that creates a good seal can cause the material to continue deforming over time.

This can lead to a loss of bolt torque and a reduction in sealing pressure, potentially resulting in leaks if not properly managed.

The Solutions: Fillers and Energizers

To counteract this, PTFE is often blended with other materials (fillers) like glass, carbon, or stainless steel. These fillers add dimensional stability and significantly reduce the tendency to creep.

In dynamic seals, a spring or O-ring is often used as an "energizer" inside the PTFE jacket to provide a constant mechanical force, ensuring the seal lips remain engaged with the hardware.

Making the Right Choice for Your Application

Selecting the right PTFE gasket depends entirely on balancing its benefits against its limitations for your specific use case.

- If your primary focus is sealing aggressive chemicals or extreme temperatures: Virgin (unfilled) PTFE is often the best choice for its absolute chemical purity and thermal performance.

- If your primary focus is mechanical stability under high pressure: A filled PTFE gasket (e.g., glass-filled) is necessary to resist creep and maintain sealing force over time.

- If your primary focus is a dynamic application with moving parts: An energized PTFE seal will provide the low friction you need while ensuring a consistent sealing force.

- If your primary focus is food, beverage, or medical use: Ensure you specify FDA-compliant virgin PTFE to meet regulatory and hygienic standards.

Ultimately, choosing PTFE is a decision for long-term reliability in environments that are simply too demanding for conventional sealing materials.

Summary Table:

| Key Property | Benefit for Your Application |

|---|---|

| Extreme Chemical Inertness | Resists virtually all acids, bases, and solvents for long-term reliability in harsh environments. |

| Wide Temperature Range (-200°C to +260°C) | Performs reliably in both cryogenic and high-temperature applications. |

| Exceptionally Low Friction | Reduces wear and energy consumption in dynamic seals without external lubricants. |

| Conformability (Cold Flow) | Creates a superior, tight seal by filling microscopic imperfections in flange surfaces. |

| Hygienic & Compliant | Meets FDA/AMS standards, making it ideal for food, medical, and pharmaceutical uses. |

Need a PTFE sealing solution that delivers long-term reliability in your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between PTFE's superior chemical resistance and the need for mechanical stability.

Whether you require virgin PTFE for absolute purity, filled PTFE for enhanced dimensional stability, or custom-designed prototypes, our expertise ensures you get the perfect seal for your specific conditions.

Contact our experts today to discuss your project requirements and discover how our precision PTFE fabrication can solve your most challenging sealing problems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications