At its core, a Polytetrafluoroethylene (PTFE) lined butterfly valve offers a unique combination of exceptional chemical resistance and a compact, quick-action design. Compared to alternatives like hard seal valves, it provides superior sealing, while its lightweight form factor makes it more space-efficient than other fluoropolymer-lined options like ball or plug valves.

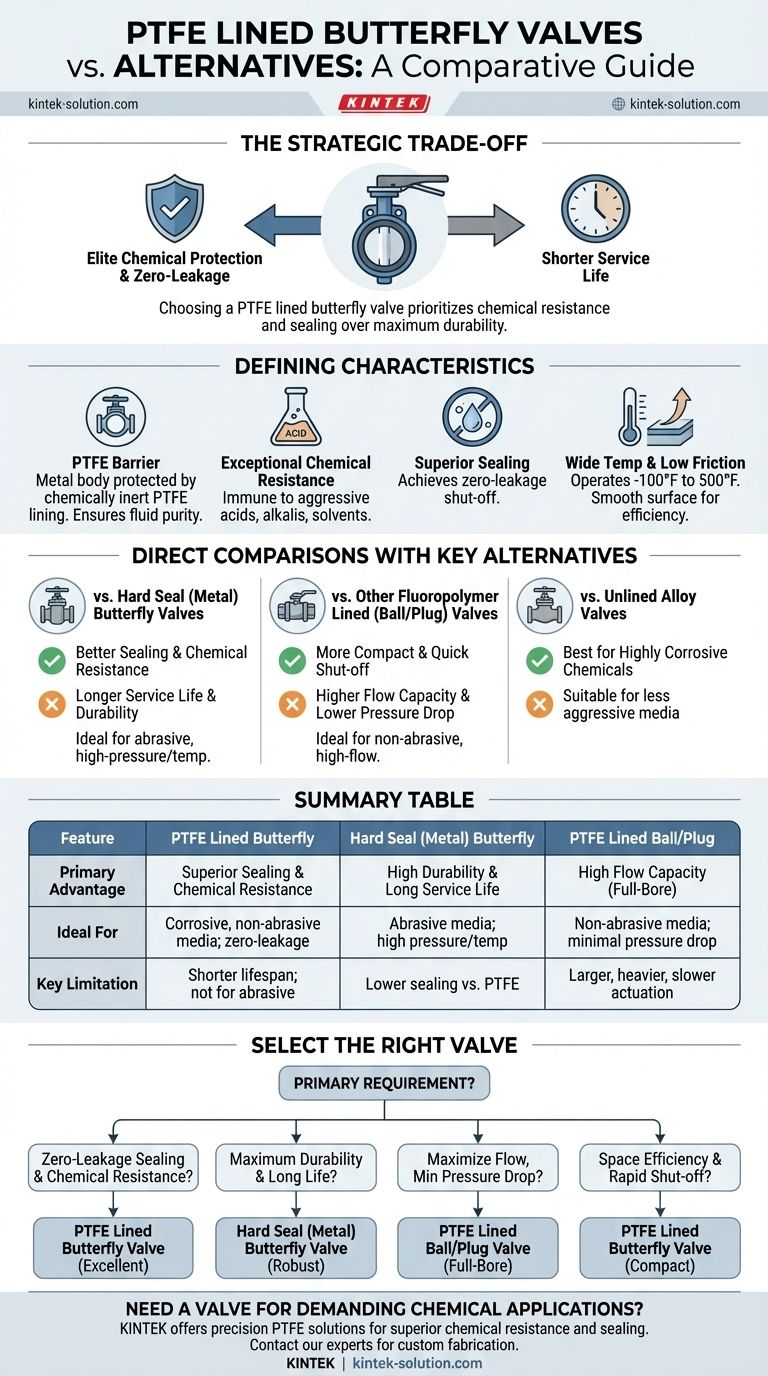

The decision to use a PTFE lined butterfly valve is a strategic trade-off. You are choosing elite chemical protection and zero-leakage sealing within a lightweight, fast-actuating body, while accepting a shorter service life compared to more durable metal-seated alternatives.

The Defining Characteristics of a PTFE Lined Butterfly Valve

A PTFE lined butterfly valve is not simply a valve made of PTFE. It is a sophisticated design where a rugged metal body, typically carbon or stainless steel, is protected by a chemically inert PTFE lining.

How It Works: The PTFE Barrier

The valve's interior body and often its central disc are completely encapsulated in PTFE. This liner acts as an impermeable barrier, isolating the structural metal components from direct contact with the process fluid.

This design ensures that corrosive media only ever touch the PTFE, preventing chemical attacks on the valve's core structure and guaranteeing fluid purity.

Exceptional Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It is virtually immune to attack from aggressive acids, alkalis, solvents, and other corrosive substances. This makes it an ideal choice for handling toxic or highly reactive media.

Superior Sealing Performance

The inherent flexibility of PTFE allows the valve disc to press firmly against the liner, creating an exceptionally tight seal. This capability enables PTFE lined butterfly valves to achieve zero-leakage shut-off, a critical requirement in chemical processing and pharmaceutical applications.

Wide Temperature Tolerance

These valves can operate effectively across a broad temperature range, typically from -100°F to 500°F (-73°C to 260°C). This versatility allows them to be used in both cryogenic and high-temperature processes.

Low Friction and Flow Efficiency

PTFE has an extremely low coefficient of friction, often compared to wet ice on wet ice. This smooth, non-stick surface prevents media from adhering to the valve's internals, reduces operational torque, and minimizes wear and tear during actuation.

Direct Comparison with Key Alternatives

Understanding how a PTFE lined butterfly valve stacks up against other options is crucial for proper selection. The choice depends entirely on the specific demands of your application.

vs. Hard Seal (Metal-Seated) Butterfly Valves

This is the most common point of comparison. A hard seal valve uses a metal disc and metal seat, making it extremely durable and resistant to abrasion.

PTFE lined valves offer far superior sealing performance, often achieving a bubble-tight seal where metal valves cannot. However, hard seal valves have a significantly longer service life and can handle much higher pressures and temperatures.

vs. Other Fluoropolymer Lined Valves (PFA/FEP)

Valves can also be lined with other fluoropolymers like PFA or FEP. While all offer excellent chemical resistance, the primary difference comes down to the valve type.

A PTFE lined butterfly valve is more compact, lighter, and better for quick shut-off than a PTFE lined ball or plug valve. However, a full-bore ball or plug valve will offer higher flow capacity with a lower pressure drop.

vs. Unlined Alloy Valves

For less aggressive media, an unlined stainless steel or specialty alloy valve may suffice. The PTFE lined valve is specifically engineered for applications where even high-grade alloys would eventually corrode, making it the definitive choice for handling highly corrosive chemicals.

Understanding the Trade-offs and Limitations

No valve is perfect for every situation. Being aware of the inherent compromises of a PTFE lined butterfly valve is key to avoiding costly failures.

Limited Lifespan and Aging

The primary drawback of PTFE is that it is a soft material prone to aging and degradation over time, especially under thermal cycling. This gives it a shorter operational lifespan compared to the robust, wear-resistant nature of metal-seated valves.

Not Ideal for Abrasive Media

The soft PTFE liner is highly susceptible to damage from abrasive particles, slurries, or crystallized media. Such conditions will quickly erode the liner, destroy the seal, and lead to valve failure. Hard seal valves are the correct choice for abrasive services.

Pressure and Temperature Boundaries

While its temperature range is wide, PTFE has clear upper limits. For applications involving extreme temperatures or very high pressures, a metal-seated valve is the only reliable option. Always verify that your operating conditions are well within the manufacturer's specified ratings for the valve.

How to Select the Right Valve for Your Application

Your choice must be driven by your single most important operational requirement.

- If your primary focus is zero-leakage sealing for corrosive chemicals: A PTFE lined butterfly valve is an excellent choice for its tight shut-off and chemical inertness.

- If your primary focus is maximum durability and long service life: A hard seal (metal-seated) butterfly valve is the more robust and wear-resistant option.

- If your primary focus is maximizing flow with minimal pressure drop: A full-bore design, such as a PTFE lined ball or plug valve, should be your first consideration.

- If your primary focus is space efficiency and rapid shut-off: The compact, quarter-turn design of the butterfly valve makes it superior to bulkier alternatives.

By clearly identifying your primary engineering goal, you can confidently select the valve that provides the best performance and value for your system.

Summary Table:

| Feature | PTFE Lined Butterfly Valve | Hard Seal (Metal) Butterfly Valve | PTFE Lined Ball/Plug Valve |

|---|---|---|---|

| Primary Advantage | Superior Sealing & Chemical Resistance | High Durability & Long Service Life | High Flow Capacity (Full-Bore) |

| Ideal For | Corrosive, non-abrasive media; zero-leakage shut-off | Abrasive media; high pressure/temperature | Non-abrasive media; minimal pressure drop |

| Key Limitation | Shorter lifespan; not for abrasive services | Lower sealing performance vs. PTFE | Larger, heavier, and slower actuation |

Need a Valve for Demanding Chemical Applications?

Selecting the right valve is critical for the safety and efficiency of your process. KINTEK specializes in manufacturing high-precision PTFE components, including custom-fabricated liners, seals, and labware.

We help engineers in the semiconductor, pharmaceutical, laboratory, and industrial sectors solve complex fluid handling challenges by providing:

- Superior Chemical Resistance: Our PTFE components offer exceptional protection against the most aggressive acids, alkalis, and solvents.

- Precision Sealing: Achieve reliable, bubble-tight shut-off for critical processes.

- Custom Fabrication: From prototype development to high-volume production, we tailor solutions to your exact specifications.

Let's discuss your application requirements. Contact our experts today for a consultation and see how our precision PTFE solutions can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability