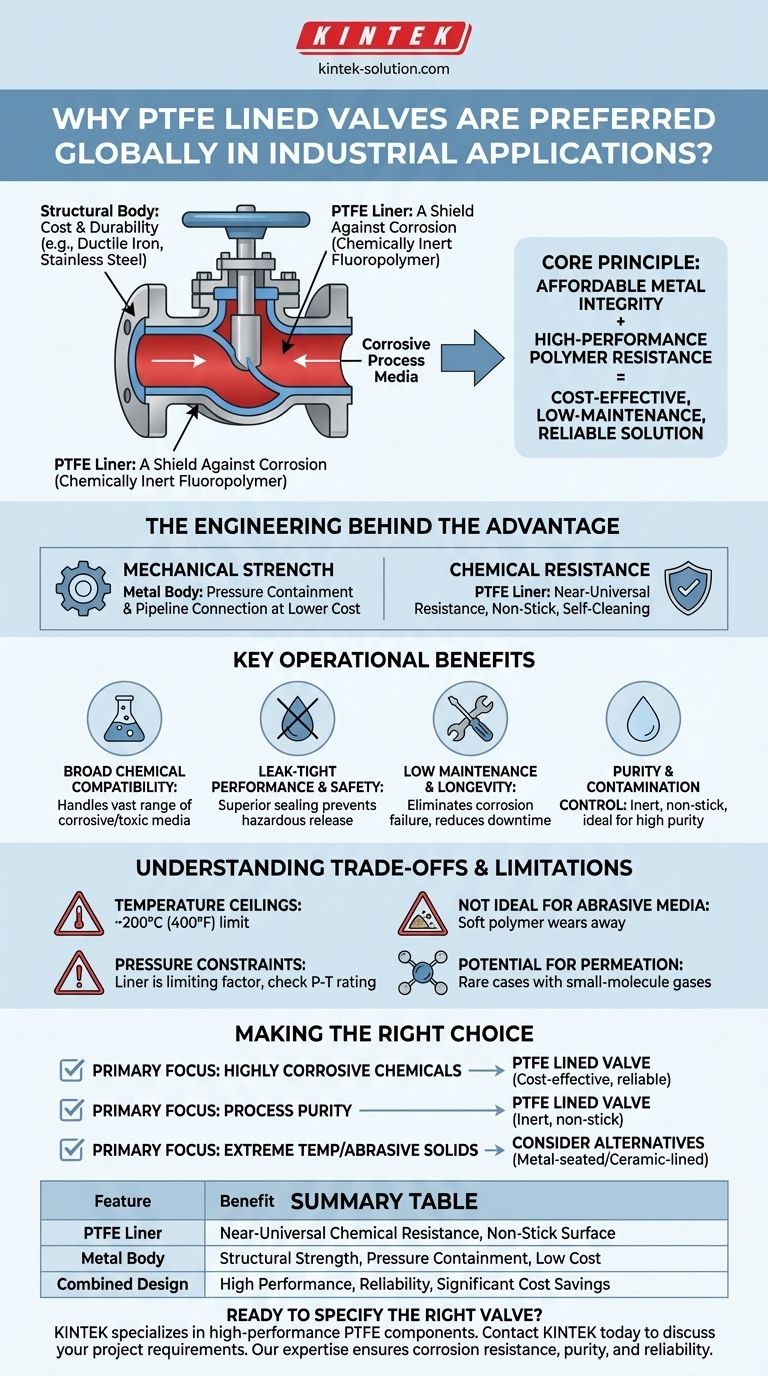

In short, PTFE lined valves are preferred globally because they offer the near-universal chemical resistance of an exotic alloy valve at a fraction of the cost. They achieve this by combining a durable, inexpensive outer body (like cast iron or steel) with a chemically inert Polytetrafluoroethylene (PTFE) liner that completely isolates the valve's structural components from corrosive process media.

The core principle is simple yet powerful: use an affordable metal for structural integrity and a high-performance polymer for chemical resistance. This design delivers a cost-effective, low-maintenance, and highly reliable solution for safely controlling the flow of aggressive and corrosive fluids.

The Engineering Behind the Advantage

To understand why this design is so dominant, you must first understand how it separates two distinct functions: mechanical strength and chemical resistance.

The Structural Body: Cost and Durability

The outer body of the valve provides the necessary mechanical strength to contain pressure and connect to the pipeline.

By using common materials like ductile iron or stainless steel, manufacturers can produce a robust and reliable valve body without the high material and sourcing costs associated with exotic alloys like Hastelloy or Monel.

The PTFE Liner: A Shield Against Corrosion

The magic happens on the inside. All wetted parts of the valve are lined with PTFE, a fluoropolymer renowned for its unique properties.

PTFE is one of the most chemically inert substances known, making it resistant to nearly all industrial acids, bases, and solvents. Its non-stick, non-wetting surface also resists buildup and can promote self-cleaning, ensuring smooth flow.

The Synthesis: High Performance, Lower Cost

This combination creates a valve that offers the performance of a high-alloy valve but with the cost and availability of a standard one.

You get elite-level protection against chemical attack in a package that is both economical and easy to source, a critical advantage for project timelines and budgets.

Key Operational Benefits

This design philosophy translates directly into tangible advantages in demanding industrial environments across chemical processing, pharmaceuticals, water treatment, and petrochemical sectors.

Broad Chemical Compatibility

The primary benefit is the ability to handle a vast range of corrosive and toxic media with a single valve type. This simplifies specification, procurement, and inventory management.

Leak-Tight Performance and Safety

The PTFE liner provides superior sealing capabilities. This ensures a leak-tight shutoff, which is critical for preventing the release of hazardous materials, protecting personnel, and ensuring environmental compliance.

Low Maintenance and Longevity

Because the process fluid never touches the metal valve body, corrosion is eliminated as a failure mode. This results in a longer service life, significantly reduced maintenance needs, and less operational downtime.

Purity and Contamination Control

In industries like pharmaceuticals, food processing, or semiconductor manufacturing, preventing contamination is paramount. The inert, non-stick nature of PTFE ensures that the valve does not leach impurities into or react with the process media.

Understanding the Trade-offs and Limitations

While highly versatile, PTFE lined valves are not a universal solution. An objective assessment requires understanding their operational limits.

Temperature Ceilings

PTFE has a distinct upper-temperature limit, typically around 200°C (400°F). For applications exceeding this, you must consider alternatives like PFA-lined valves for higher temperatures or valves made from solid alloys.

Pressure Constraints

While the metal body provides pressure containment, the liner itself can be a limiting factor. The valve's pressure-temperature (P-T) rating must be carefully checked to ensure it is suitable for the intended service conditions.

Not Ideal for Abrasive Media

PTFE is a relatively soft polymer. It is not recommended for controlling slurries or fluids containing abrasive particles, as these can physically wear away the liner and compromise its integrity over time.

Potential for Permeation

In rare cases with very small-molecule gases (like chlorine or hydrogen), permeation through the liner can occur over time. For these specific services, a detailed engineering review is necessary.

Making the Right Choice for Your Application

Selecting the correct valve hinges on your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: A PTFE lined valve is almost always the most cost-effective and reliable solution, avoiding the high cost and long lead times of exotic alloys.

- If your primary focus is process purity and preventing contamination: The inert, non-stick properties of PTFE make it an ideal choice for high-purity applications in pharma, food, and electronics.

- If your primary focus is extreme temperatures or abrasive solids: You must carefully evaluate the valve's specifications and consider purpose-built alternatives like metal-seated or ceramic-lined valves.

By balancing the exceptional chemical resistance of PTFE with its known physical limitations, you can confidently specify a valve solution that ensures safety, reliability, and economic efficiency.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Liner | Near-universal chemical resistance and non-stick surface |

| Metal Body | Structural strength and pressure containment at low cost |

| Combined Design | High performance and reliability with significant cost savings |

| Key Industries | Chemical Processing, Pharmaceuticals, Water Treatment, Petrochemicals |

Ready to specify the right valve for your demanding application?

At KINTEK, we specialize in high-performance PTFE components, including custom-fabricated liners and seals for valves and other critical equipment. Our expertise in precision manufacturing ensures your components meet the highest standards for corrosion resistance, purity, and reliability.

Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we deliver cost-effective solutions without compromising on quality.

Contact KINTEK today to discuss your project requirements and discover how our PTFE expertise can enhance your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How are Teflon bushings used in the automotive industry? For Superior Performance and Maintenance-Free Operation

- What are the overall advantages of using PTFE bellows? Superior Chemical Resistance & Purity

- What are some common applications of Teflon bushings in machinery? Solve Friction in Harsh Environments

- How do the non-stick properties of Teflon bushings benefit their performance? Boost Reliability & Cut Maintenance

- What temperature range can PTFE envelope gaskets withstand? -200°C to +260°C for Extreme Conditions

- Are Teflon PTFE sheets safe for food-related uses? Ensuring Food Safety with Pure PTFE

- What types of fasteners can be made from PTFE? A Guide to Chemical-Resistant, Low-Friction Components

- How does the PTFE lining in diaphragm valves enhance performance? Boost Reliability in Harsh Chemical Processes