At its core, the economic advantage of ePTFE gaskets stems from their versatility and reliability, which significantly reduce costs associated with inventory, labor, and operational downtime. Because ePTFE can be easily cut to any shape on-site from a single sheet, it eliminates the need for pre-fabricated gaskets, drastically simplifying procurement and lowering inventory requirements.

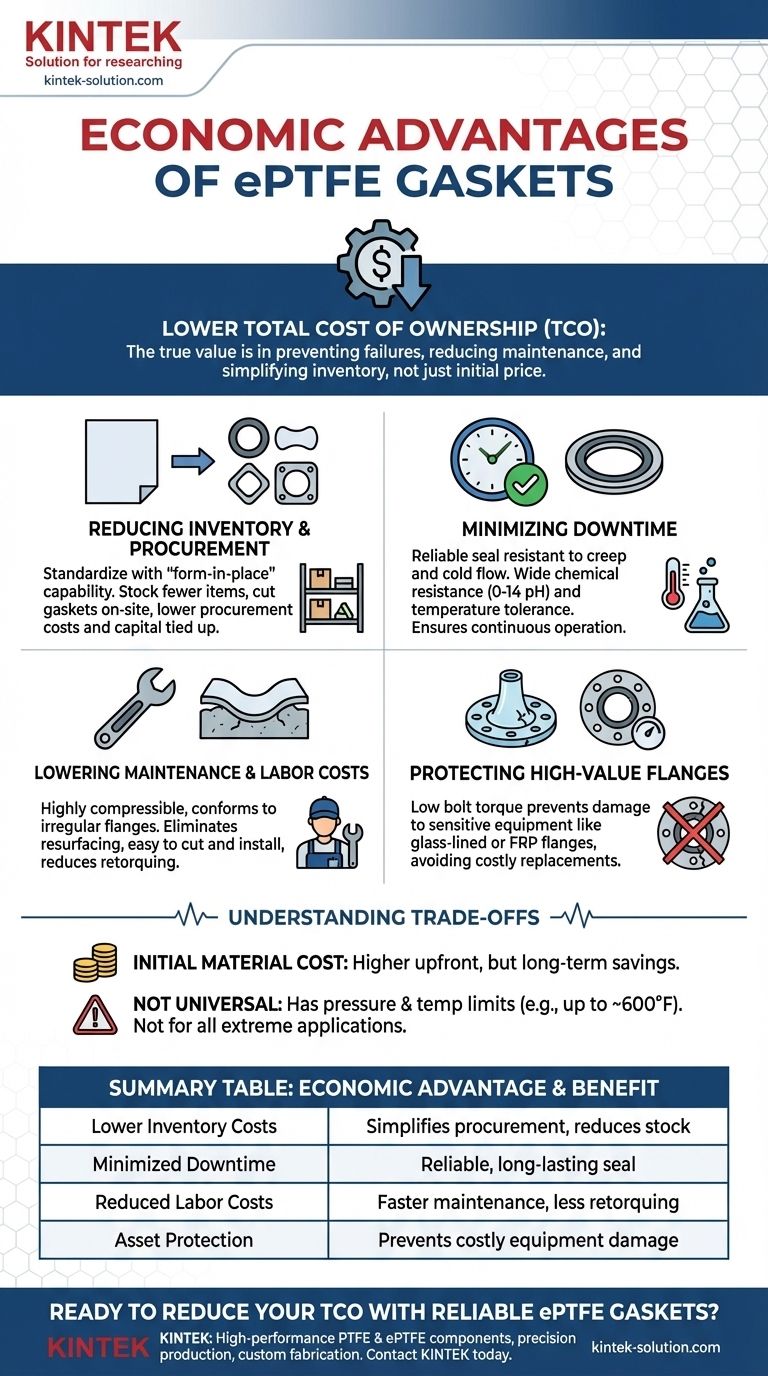

The primary economic benefit of ePTFE gaskets is not found in their initial purchase price, but in a lower Total Cost of Ownership (TCO). This is achieved by preventing costly failures, reducing maintenance labor, and simplifying inventory management.

The Link Between Technical Performance and Financial Gain

The true value of ePTFE (expanded Polytetrafluoroethylene) is realized when you connect its superior material properties to common industrial pain points like downtime, maintenance, and complex supply chains.

Reducing Inventory and Procurement Complexity

The most direct economic advantage is the ability to standardize. Instead of stocking dozens of different pre-cut gasket sizes, a facility can stock a few sheets of ePTFE material.

This "form-in-place" capability means technicians can fabricate the exact gasket needed on the spot. This dramatically lowers procurement costs, reduces capital tied up in slow-moving inventory, and eliminates project delays caused by waiting for a specific part.

Minimizing Downtime with a Reliable Seal

Unplanned downtime is often the single greatest expense in an industrial setting. The material properties of ePTFE directly combat the primary causes of gasket failure.

Its unique structure makes it highly resistant to creep and cold flow, common failure points in standard PTFE that lead to leaks over time. This stability means the seal lasts longer and requires less frequent retorquing, ensuring continuous operation.

Furthermore, its exceptional chemical resistance (across the 0-14 pH range) and wide temperature tolerance mean one material can handle many different services, reducing the risk of failure from incorrect material selection.

Lowering Maintenance and Labor Costs

ePTFE gaskets are highly compressible and flexible, allowing them to conform to and seal rough or irregular flange surfaces.

This adaptability often eliminates the need for expensive and time-consuming flange resurfacing. Its ease of cutting and installation also reduces the time and labor required for maintenance tasks.

Protecting High-Value Flange Assets

Certain equipment, such as glass-lined steel, FRP (Fiberglass Reinforced Plastic), or other fragile flanges, can be easily damaged by the high bolt loads required to seat harder gasket materials.

ePTFE's softness and high compressibility allow it to create a tight seal with significantly lower bolt torque. This inherent property protects expensive and sensitive equipment from cracking or damage, avoiding catastrophic replacement costs.

Understanding the Trade-offs

While ePTFE offers significant advantages, an objective evaluation requires acknowledging its limitations. A strategic decision is an informed one.

Initial Material Cost

The upfront purchase price of an ePTFE sheet may be higher than that of some commodity gasketing materials like certain compressed non-asbestos or rubber sheets. The economic justification relies entirely on calculating the long-term savings from reduced maintenance, inventory, and downtime.

Handling and Reusability

While ePTFE is tough, its softness requires careful handling to avoid creating nicks or surface defects that could compromise the seal.

The references note that gaskets can sometimes be reused, but this should be approached with extreme caution. Reuse is highly dependent on the application, condition of the gasket after service, and company policy; it should not be the primary economic justification for its selection.

Not a Universal Solution

Despite its versatility, ePTFE is not the answer for every application. It has clear temperature and pressure limits (e.g., up to ~600°F / 315°C and 3000+ psi, depending on the specific product and flange).

In applications involving extreme pressures, temperatures, or specific chemical interactions, metallic or semi-metallic gaskets may be the only appropriate choice.

Making the Right Choice for Your Goal

Selecting the right gasket is a strategic decision that should align with your primary operational objective.

- If your primary focus is minimizing operational downtime: ePTFE is an exceptional choice due to its long-term reliability and resistance to common failure modes like creep and cold flow.

- If your primary focus is simplifying maintenance and inventory: The ability to cut any gasket from a single sheet material makes ePTFE a powerful tool for streamlining procurement and plant-wide standardization.

- If your primary focus is protecting fragile or imperfect flanges: The high compressibility and low seating stress of ePTFE make it one of the safest and most effective options available.

Ultimately, choosing ePTFE is an investment in operational reliability that pays dividends by reducing the hidden costs of failure.

Summary Table:

| Economic Advantage | How ePTFE Delivers | Key Benefit |

|---|---|---|

| Lower Inventory Costs | Cut any gasket from a single sheet on-site | Simplifies procurement and reduces stock |

| Minimized Downtime | Superior resistance to creep, cold flow, and chemicals | Creates a reliable, long-lasting seal |

| Reduced Labor Costs | Easy to cut and install; conforms to imperfect surfaces | Faster maintenance and less retorquing |

| Asset Protection | Low seating stress protects fragile flanges | Prevents costly equipment damage |

Ready to reduce your Total Cost of Ownership with reliable ePTFE gaskets?

At KINTEK, we specialize in manufacturing high-performance PTFE and ePTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get the exact sealing solution your operation needs to boost efficiency and cut costs.

Contact KINTEK today to discuss your application and discover how our ePTFE solutions can deliver significant economic advantages for your business.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE chemically resistant? The Power of Fluorine's Protective Shield

- What temperature range can PTFE seals withstand? -200°C to 260°C & Beyond

- How does PTFE's soft nature affect surface finish quality during machining? Mastering the Slice, Not Tear, Process

- How do composite bellows compare to PTFE bellows? Choose the Right Bellow for Your Application

- Can Teflon washers be used without lubricant? Yes, for Maximum Reliability and Low Maintenance

- What are the main properties of PTFE sheets? Unlock Extreme Performance for Your Applications

- What industries commonly use glass-filled PTFE rods? Enhance Performance in Aerospace, Medical & More

- Why are spring-energized PTFE seals suitable for the aerospace industry? Unmatched Reliability in Extreme Conditions