Beyond PTFE, the world of gasket materials is vast and highly specialized, encompassing everything from traditional natural products to advanced synthetic elastomers and composites. While Polytetrafluoroethylene (PTFE) is renowned for its chemical inertness and low friction, many other materials offer superior performance in specific conditions related to temperature, pressure, flexibility, and cost. Understanding these alternatives is crucial for achieving a reliable and long-lasting seal.

The goal is not to find the single "best" gasket material, but to precisely match a material's unique properties to the specific demands of your application. Every choice, from simple cork to high-performance graphite, represents a calculated trade-off between temperature resistance, chemical compatibility, pressure rating, and cost.

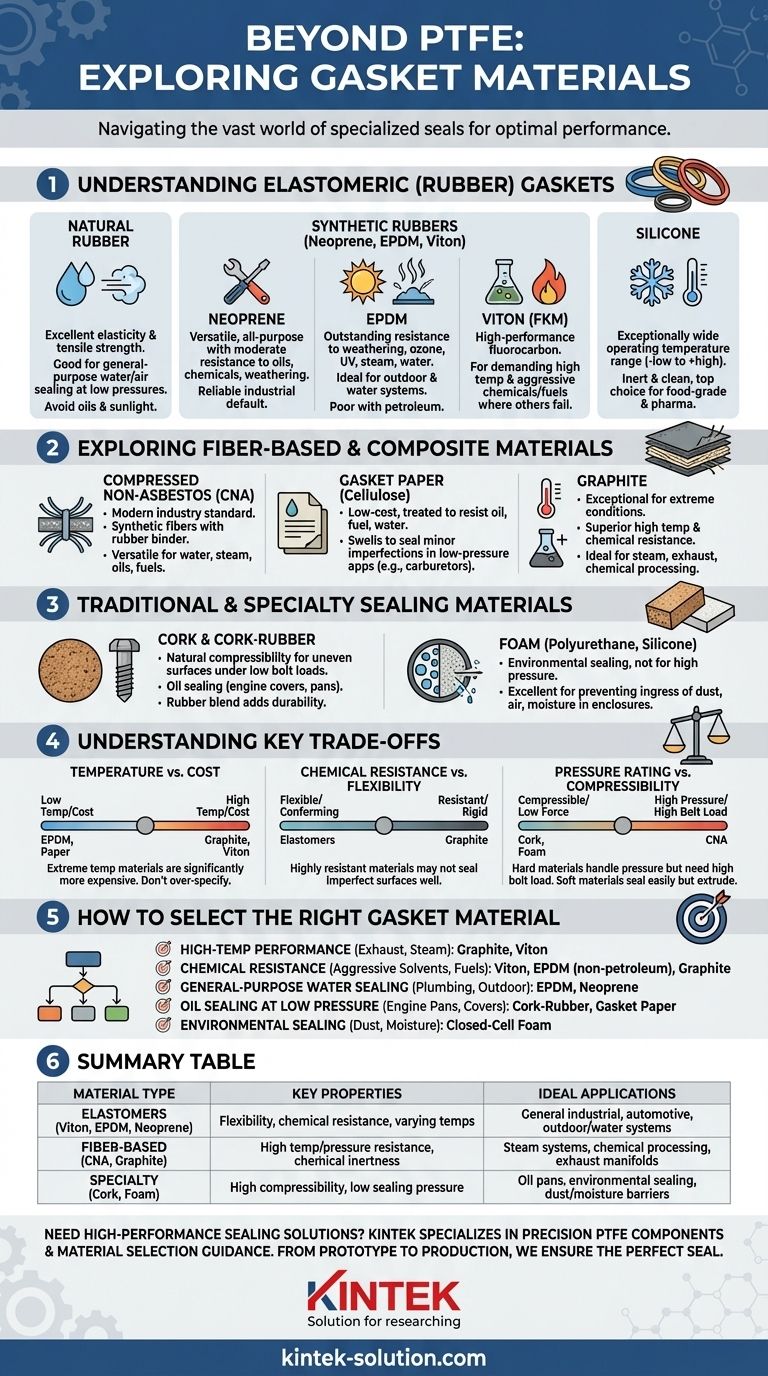

Understanding Elastomeric (Rubber) Gaskets

Elastomers are the most common category of gasket materials, prized for their flexibility and ability to conform to surface imperfections. However, not all rubbers are created equal.

Natural Rubber

Natural rubber offers excellent elasticity and tensile strength, making it a good choice for general-purpose applications with no exposure to oils, ozone, or sunlight. It is typically used for sealing water or air at low pressures.

Synthetic Rubbers (Neoprene, EPDM, Viton)

Neoprene is a versatile, all-purpose synthetic rubber with moderate resistance to oils, chemicals, and weathering. It serves as a reliable default for a wide range of industrial applications.

EPDM (Ethylene Propylene Diene Monomer) provides outstanding resistance to weathering, ozone, UV light, steam, and water. This makes it the preferred material for outdoor applications and water systems, but it performs poorly with petroleum-based fluids.

Viton (FKM) is a high-performance fluorocarbon elastomer. It is specified for demanding applications involving high temperatures and aggressive chemicals, fuels, and oils, where lesser materials would quickly degrade.

Silicone

Silicone stands out for its exceptionally wide operating temperature range, remaining flexible at very low temperatures and stable at high temperatures. It is also inert and clean, making it a top choice for food-grade and pharmaceutical applications.

Exploring Fiber-Based and Composite Materials

These materials combine fibers with binders to create a dense, robust sheet capable of handling higher pressures than most pure elastomers.

Compressed Non-Asbestos (CNA)

CNA sheets are the modern industry standard, developed to replace asbestos-based materials. They typically consist of aramid or other synthetic fibers bonded with a rubber binder (like NBR), creating a versatile material suitable for water, steam, oils, and fuels.

Gasket Paper (Cellulose)

Gasket paper is a low-cost material treated to resist oil, fuel, and water. It functions by swelling slightly upon contact with fluids, which helps it fill minor flange imperfections and create a tight seal in low-pressure applications like carburetors and fuel pumps.

Graphite

Flexible graphite is an exceptional material for extreme conditions. It offers superior performance at very high temperatures and is resistant to nearly all chemicals, making it ideal for steam systems, exhaust manifolds, and chemical processing. It can be used as a flexible sheet or laminated with a metal core for added strength.

Traditional and Specialty Sealing Materials

While less common in high-performance industrial settings, these materials still serve important niche roles.

Cork & Cork-Rubber Composites

Cork's natural compressibility makes it perfect for sealing uneven surfaces under very low bolt loads. It is often used for oil sealing in applications like engine valve covers and oil pans. Blending cork with rubber enhances its durability and resistance to tearing.

Foam (Polyurethane, Silicone)

Foam materials, available in open-cell or closed-cell structures, are not intended for high-pressure fluid sealing. Instead, they excel at environmental sealing—preventing the ingress of dust, air, and moisture in enclosures, doors, and electronic housings.

Understanding the Key Trade-offs

Selecting a gasket requires balancing competing properties. No single material is perfect for every scenario.

Temperature vs. Cost

Materials engineered for extreme temperatures, such as Graphite and Viton, are significantly more expensive than general-purpose options like EPDM or paper. Over-specifying for temperature is a common and costly mistake.

Chemical Resistance vs. Flexibility

Highly resilient materials like graphite may be less forgiving of flange imperfections than a soft, conforming elastomer. The most chemically resistant option may not create the most effective seal if your flange surfaces are not perfectly flat.

Pressure Rating vs. Compressibility

Hard, dense materials like CNA can withstand immense pressure but require a high bolt load to properly "seat" and create a seal. Softer, more compressible materials like cork or foam seal with minimal force but will be extruded or destroyed by high pressure.

How to Select the Right Gasket Material

Your application's operating conditions are the only factor that matters. Use this guide to narrow your choices.

- If your primary focus is high-temperature performance (e.g., exhaust, steam): Graphite or high-temperature synthetics like Viton are the primary candidates.

- If your primary focus is chemical resistance (e.g., aggressive solvents, fuels): Viton, EPDM (for non-petroleum chemicals), and Graphite offer the best protection.

- If your primary focus is general-purpose water sealing (e.g., plumbing, outdoor use): EPDM and Neoprene provide an excellent balance of performance and cost.

- If your primary focus is oil sealing at low pressure (e.g., engine pans, covers): Cork-rubber composites and gasket paper are cost-effective and highly suitable.

- If your primary focus is environmental sealing (e.g., dust, moisture): Closed-cell foam gaskets are the ideal choice for their high compressibility and barrier properties.

A successful seal is achieved not by choosing the most advanced material, but the one best matched to your system's operational demands.

Summary Table:

| Material Type | Key Properties | Ideal Applications |

|---|---|---|

| Elastomers (Viton, EPDM, Neoprene) | Flexibility, chemical resistance, varying temperature ranges | General industrial, automotive, outdoor/water systems |

| Fiber-Based (CNA, Graphite) | High temperature/pressure resistance, chemical inertness | Steam systems, chemical processing, exhaust manifolds |

| Specialty (Cork, Foam) | High compressibility, low sealing pressure | Oil pans, environmental sealing, dust/moisture barriers |

Struggling to find the right gasket material for your specific temperature, pressure, or chemical requirements? At KINTEK, we specialize in manufacturing high-performance PTFE components (seals, liners, labware) and understand the critical role material selection plays in sealing solutions. Whether you need a custom prototype or high-volume production for the semiconductor, medical, laboratory, or industrial sectors, our precision manufacturing ensures a perfect seal every time. Let our experts help you solve your sealing challenge — contact us today for a consultation!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the benefits of PTFE packing? Superior Sealing for Harsh Chemicals and High Purity

- What are the limitations of Teflon encapsulated O-rings in terms of chemical resistance? Key Weaknesses to Avoid Seal Failure

- What role does PTFE play in industrial equipment maintenance? Extend Lifespan & Reduce Downtime

- How does the heat resistance of Teflon sheets benefit industrial applications? Unlock Performance Under Thermal Stress

- What are the advantages of glass fiber filled PTFE? Boost Strength & Resist Wear

- How does thermal expansion affect PTFE machining? Master Heat Management for Dimensional Accuracy

- How does low friction benefit mechanical systems using PTFE washers? Boost Efficiency & Lifespan

- How do you install a PTFE coating thrust washer in a fishing reel? A Simple Upgrade for Smoother Casting & Longer Distance