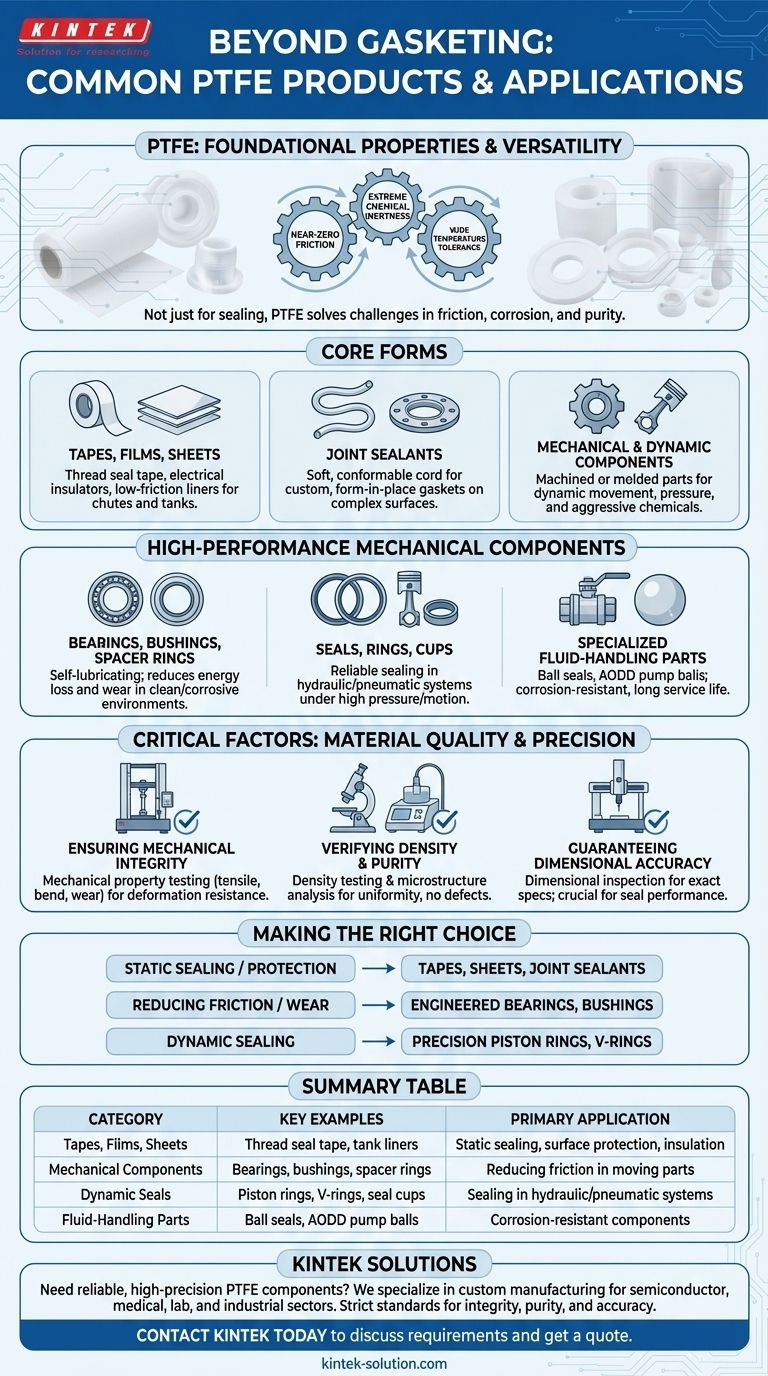

Beyond its well-known use in gasketing, Polytetrafluoroethylene (PTFE) is engineered into a vast array of high-performance products. Its applications span from simple tapes and sheets to complex, precision-machined components like bearings, seals, piston rings, and rollers used in demanding industrial environments.

The true value of PTFE lies in its unique combination of properties—near-zero friction, extreme chemical inertness, and wide temperature tolerance. This versatility is why it's not just a sealing material, but a foundational component for solving engineering challenges related to friction, corrosion, and purity.

Core Applications and Product Forms

PTFE's adaptability allows it to be manufactured into several foundational forms, each serving a distinct purpose in industrial and commercial settings.

Tapes, Films, and Sheets

PTFE tapes are most commonly recognized as thread seal tape for plumbing, but they are also used as high-performance electrical insulators. Sheets and films are frequently used as low-friction, chemically resistant liners for chutes, tanks, and other vessels where material flow and corrosion resistance are critical.

Joint Sealants

This form of PTFE is a soft, conformable cord that is used to create custom, form-in-place gaskets. It is ideal for sealing large, complex, or damaged flange surfaces where a standard pre-cut gasket would fail.

Mechanical and Dynamic Components

This is where PTFE's performance characteristics are most critical. It is machined or molded into a wide variety of parts designed for dynamic applications involving movement, pressure, and aggressive chemicals.

High-Performance Mechanical Components

The majority of non-gasket PTFE products are engineered parts designed to reduce wear, prevent leaks, and withstand harsh operating conditions in machinery.

Bearings, Bushings, and Spacer Rings

Due to its incredibly low coefficient of friction, PTFE is an ideal material for self-lubricating bearings and bushings. These components reduce energy loss and prevent wear between moving parts without requiring external lubrication, which is vital in clean or corrosive environments.

Seals, Rings, and Cups

Components like V-rings, piston rings, piston cups, and seal rings are crucial in hydraulic and pneumatic systems. They leverage PTFE's flexibility and durability to create a reliable seal between moving parts, preventing fluid or gas leakage under high pressure and motion.

Specialized Fluid-Handling Parts

In pumps and valves, PTFE is used for components like ball seals and AODD (Air-Operated Double-Diaphragm) pump balls. Its chemical inertness ensures it will not corrode or contaminate the fluid being moved, and its durability provides a long service life.

The Critical Factor: Material Quality and Precision

The reliability of any PTFE component, from a simple liner to a complex piston ring, depends entirely on the quality of the material and the precision of its manufacturing. This is not a material where "good enough" is acceptable.

Ensuring Mechanical Integrity

For a bearing or seal to function, it must resist deformation and wear. Mechanical property testing (tensile, bend, and wear tests) is performed to guarantee that the component can withstand the physical stresses of its intended application without failing.

Verifying Material Density and Purity

In high-pressure applications, any voids or inconsistencies in the PTFE material can become a point of failure. Density testing and microstructure analysis ensure that the material is uniform and free from defects that could compromise its structural integrity.

Guaranteeing Dimensional Accuracy

A seal that is even a fraction of a millimeter off-spec will fail to perform its function. Dimensional inspection using tools like Coordinate Measuring Machines (CMMs) is essential to confirm that every component is manufactured to the exact required dimensions and surface finish.

Making the Right Choice for Your Goal

Selecting the correct PTFE product requires matching the form factor to the primary engineering challenge you need to solve.

- If your primary focus is static sealing or surface protection: PTFE tapes, sheets, and joint sealants provide an excellent barrier against chemicals and moisture.

- If your primary focus is reducing friction and wear in moving parts: Look to engineered bearings, bushings, and spacer rings to ensure smooth, self-lubricating operation.

- If your primary focus is dynamic sealing in fluid power systems: Precision-made piston rings, V-rings, and seal cups are designed specifically for this demanding task.

Understanding this wide range of products empowers you to apply PTFE's unique properties to solve specific engineering challenges far beyond simple gasketing.

Summary Table:

| PTFE Product Category | Key Examples | Primary Application |

|---|---|---|

| Tapes, Films, Sheets | Thread seal tape, tank liners | Static sealing, surface protection, insulation |

| Mechanical Components | Bearings, bushings, spacer rings | Reducing friction in moving parts |

| Dynamic Seals | Piston rings, V-rings, seal cups | Sealing in hydraulic/pneumatic systems |

| Fluid-Handling Parts | Ball seals, AODD pump balls | Corrosion-resistant components for pumps/valves |

Need a reliable, high-precision PTFE component?

The performance of your application depends on the quality and precision of your PTFE parts. At KINTEK, we specialize in manufacturing custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors. We ensure every part meets strict standards for mechanical integrity, material purity, and dimensional accuracy, from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific requirements and get a quote for a solution that delivers superior performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key characteristics of PTFE ram extrusion? Efficient Production of Long PTFE Rods & Tubes

- What are the desirable properties of PTFE as a sealing material? Unlock Superior Performance in Extreme Conditions

- What temperature range can PTFE flange gaskets withstand? From Cryogenic -200°C to High-Temp +260°C

- What are the main disadvantages of pure PTFE? Understand Its Critical Limitations for Your Application

- What are PTFE envelope gaskets? The Ultimate Sealing Solution for Corrosive Environments

- What support is available for selecting the right PTFE valve design and size? Get Expert Guidance for Your Application

- What benefits do PTFE spacer rings offer to customers? Achieve Unmatched Reliability and Lower Costs

- What are the three basic types of Teflon back-up rings? Choose the Right Design for Your Sealing System