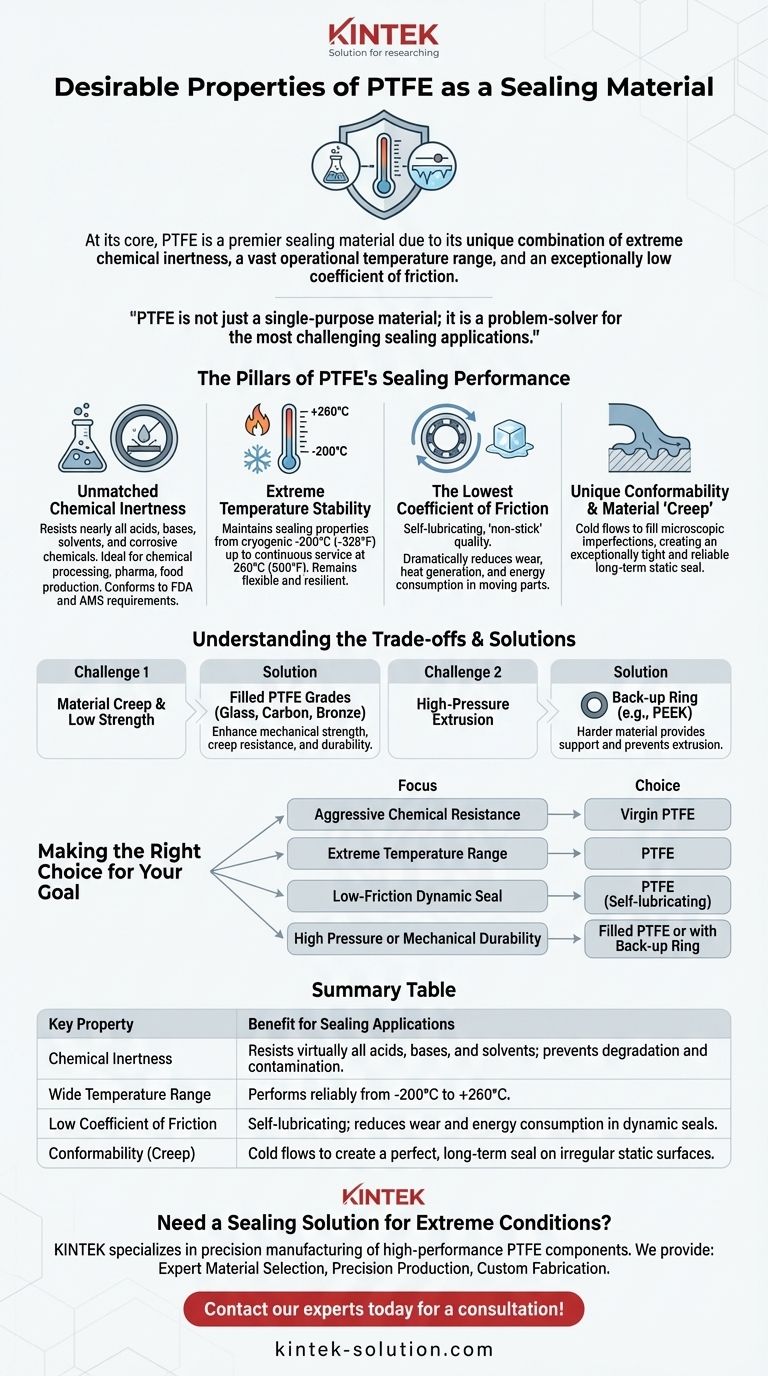

At its core, PTFE is a premier sealing material due to its unique combination of extreme chemical inertness, a vast operational temperature range, and an exceptionally low coefficient of friction. These properties ensure it remains stable, compliant, and durable in demanding environments where most other materials would quickly degrade or fail.

PTFE is not just a single-purpose material; it is a problem-solver for the most challenging sealing applications. Its value comes from simultaneously resisting chemical attack, withstanding extreme temperatures, and minimizing friction in a way no other polymer can.

The Pillars of PTFE's Sealing Performance

To understand why PTFE is so effective, we must look at its fundamental material characteristics. Each property directly addresses a common failure point in sealing systems.

Unmatched Chemical Inertness

PTFE is famously non-reactive, resisting attack from nearly all industrial acids, bases, solvents, and corrosive chemicals. This makes it an ideal choice for applications in chemical processing, pharmaceuticals, and food production.

This inertness ensures the seal will not swell, weaken, or degrade upon contact with aggressive media, preserving its integrity and preventing contamination of the system. It readily conforms to FDA and AMS requirements for these reasons.

Extreme Temperature Stability

PTFE maintains its sealing properties across an exceptionally wide temperature spectrum, from cryogenic conditions at -200°C (-328°F) up to continuous service at 260°C (500°F).

Where other polymers would become brittle and crack in the cold or soften and fail in the heat, PTFE remains flexible and resilient. This makes it indispensable in aerospace, automotive, and oil & gas applications.

The Lowest Coefficient of Friction

Among all solid materials, PTFE has one of the lowest coefficients of friction, often compared to wet ice on wet ice. This self-lubricating, "non-stick" quality is critical for dynamic seals involving moving parts.

This property dramatically reduces wear and heat generation, prolonging the life of both the seal and the equipment it protects. It also lowers the energy required to overcome friction in the system.

Unique Conformability and Material 'Creep'

A critical property of PTFE is its tendency to cold flow, or "creep." Unlike materials that have a 'memory' and try to return to their original shape, PTFE deforms under pressure to fill microscopic imperfections on mating surfaces.

For static seals, this is a significant advantage. It allows the material to conform perfectly to the housing, creating an exceptionally tight and reliable long-term seal.

Understanding the Trade-offs

No material is perfect for every situation. While PTFE's properties are highly desirable, it's crucial to understand its limitations to apply it correctly.

The Challenge of Material Creep

The same creep that creates a great static seal can be a liability under certain conditions. In applications with high mechanical loads or fluctuating pressures, the material can permanently deform and extrude from the sealing gap, leading to a loss of sealing force over time.

Relatively Low Mechanical Strength

Compared to other engineering polymers, virgin PTFE is a soft material. It has lower tensile strength and abrasion resistance, making it susceptible to damage in high-wear or high-pressure environments.

This is often mitigated by creating filled PTFE grades, where materials like glass fiber, carbon, or bronze are added to enhance mechanical strength, creep resistance, and durability.

High-Pressure Extrusion

Because it is soft, PTFE can be forced out of the sealing gap in very high-pressure applications. This is why it is frequently paired with a back-up ring made from a harder material like PEEK to provide support and prevent extrusion.

Making the Right Choice for Your Goal

Selecting the right sealing material depends entirely on the demands of your application.

- If your primary focus is aggressive chemical resistance: PTFE is the default choice, offering unparalleled protection against almost any media.

- If your primary focus is an extreme temperature range: PTFE's stability from cryogenic cold to high heat makes it one of the few viable options.

- If your primary focus is a low-friction dynamic seal: PTFE's self-lubricating nature is ideal for reducing wear and energy consumption in moving systems.

- If your primary focus is high pressure or mechanical durability: Use a filled grade of PTFE or incorporate a rigid back-up ring to prevent failure from creep and extrusion.

Ultimately, PTFE provides a robust and reliable sealing solution for the operational extremes where conventional materials simply cannot perform.

Summary Table:

| Key Property | Benefit for Sealing Applications |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents degradation and contamination. |

| Wide Temperature Range | Performs reliably from -200°C to +260°C (-328°F to 500°F). |

| Low Coefficient of Friction | Self-lubricating; reduces wear and energy consumption in dynamic seals. |

| Conformability (Creep) | Cold flows to create a perfect, long-term seal on irregular static surfaces. |

Need a Sealing Solution for Extreme Conditions?

PTFE's unique properties solve the most challenging sealing problems in semiconductor, medical, laboratory, and industrial applications. At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—from custom seals and liners to complex labware.

We provide:

- Expert Material Selection: Guidance on virgin or filled PTFE grades to meet your specific pressure, chemical, and temperature requirements.

- Precision Production: Components manufactured to the highest tolerances for reliable, leak-free performance.

- Custom Fabrication: From rapid prototypes to high-volume production runs.

Let us engineer the perfect seal for your application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How do fillers alter PTFE's machining properties? A Guide to Taming Abrasive Composites

- Why are PTFE lined check valves ideal for commercial environments? Ensure System Integrity in Corrosive Applications

- Why is PTFE used in chemical transport and storage systems? Unmatched Chemical & Thermal Resistance

- What are the characteristics of PEEK-filled PTFE? Enhanced Durability for High-Load Applications

- What are the main technical parameters for calculating PTFE rubber bearing pads? Ensure Structural Integrity & Movement

- How does the hydrophobic property of Teflon coatings work? The Science of Water Repellency

- What is the importance of torque checks in PTFE butterfly valves? Prevent Leaks & Extend Valve Life

- What are the key features of PTFE? Unmatched Performance for Extreme Industrial Environments