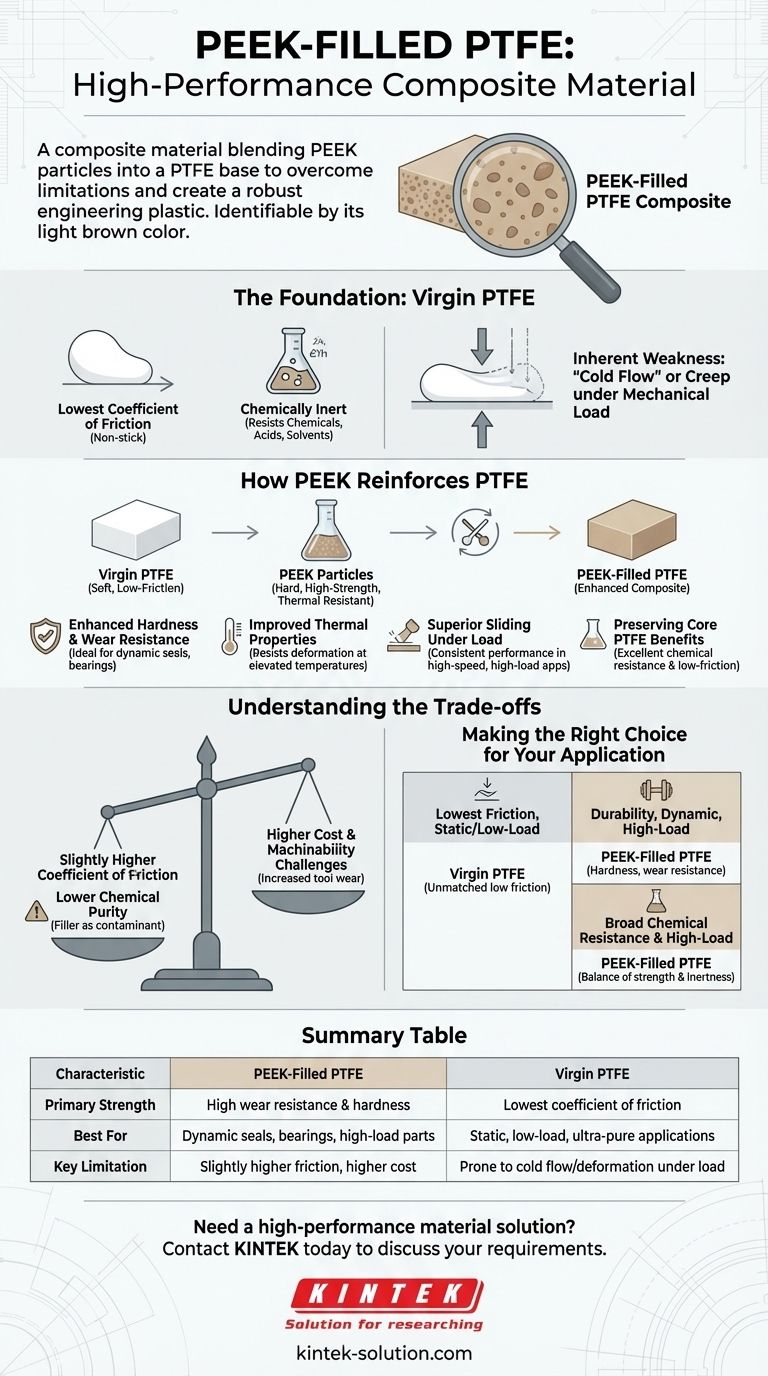

At its core, PEEK-filled PTFE is a high-performance composite material designed to overcome the physical limitations of pure PTFE. By blending Polyetheretherketone (PEEK) particles into a Polytetrafluoroethylene (PTFE) base, it gains significantly increased surface hardness, thermal resistance, and durability, making it ideal for demanding dynamic applications where pure PTFE would fail. It is most easily identified by its characteristic light brown color.

The central purpose of adding PEEK to PTFE is to transform a soft, low-friction material into a robust engineering plastic. This enhancement provides the mechanical strength needed for high-load, high-speed components without sacrificing the exceptional chemical and temperature resistance inherent to PTFE.

The Foundation: Understanding Virgin PTFE

The Strengths of the Base Material

Virgin PTFE is an extraordinary polymer. It possesses the lowest coefficient of friction of any known solid, making it incredibly non-stick.

It is also almost completely chemically inert, resisting nearly all industrial chemicals, acids, and solvents across a wide temperature range.

The Inherent Weakness

The primary limitation of virgin PTFE is its softness. Under mechanical load, it is prone to a phenomenon known as "cold flow," or creep, where the material slowly deforms. This makes it unsuitable for high-load bearings or dynamic seals.

How PEEK Reinforces PTFE

Adding a filler like PEEK (typically up to 20%) directly addresses the mechanical weaknesses of virgin PTFE, creating a far more capable composite.

Enhanced Hardness and Wear Resistance

PEEK is a very hard, high-strength polymer. Dispersing it within the PTFE matrix dramatically increases the composite's surface hardness and overall durability.

This makes PEEK-filled PTFE highly resistant to wear and abrasion, extending the service life of components like seals, bearings, and bushings, especially in dynamic applications involving movement and friction.

Improved Thermal Properties

The addition of PEEK improves the material's dimensional stability at elevated temperatures.

While virgin PTFE has a wide operating temperature range, PEEK-filled grades are better at resisting deformation and maintaining their strength and hardness as temperatures rise.

Superior Sliding Properties Under Load

While virgin PTFE has a lower static coefficient of friction, PEEK-filled PTFE excels in high-load, high-speed sliding applications.

It maintains its low-friction characteristics without the rapid wear and deformation that would occur with the unfilled material, ensuring more consistent performance over time.

Preserving Core PTFE Benefits

Crucially, this composite retains the key benefits of its base material. It continues to offer excellent chemical resistance and a very low-friction surface, providing a unique combination of mechanical strength and chemical inertness.

Understanding the Trade-offs

No material choice is without compromise. Understanding the limitations of PEEK-filled PTFE is essential for proper application.

Coefficient of Friction

While excellent, the static coefficient of friction for PEEK-filled PTFE is slightly higher than that of virgin PTFE. If the application demands the absolute lowest friction possible with minimal load, pure PTFE is superior.

Chemical Purity and Compatibility

The presence of the PEEK filler means the material is no longer pure Polytetrafluoroethylene. For applications in ultra-pure chemical or semiconductor manufacturing, the potential for the filler to be a contaminant may make virgin PTFE a better choice.

Cost and Machinability

Filled grades of PTFE are generally more expensive than their virgin counterparts. The added hardness can also increase tool wear during machining processes, potentially adding to fabrication costs.

Making the Right Choice for Your Application

Selecting the correct material requires a clear understanding of your primary engineering goal.

- If your primary focus is the lowest possible friction for a static or low-load part: Virgin PTFE is the unmatched choice due to its exceptionally low coefficient of friction.

- If your primary focus is durability for dynamic seals, bearings, or wear rings: PEEK-filled PTFE provides the necessary hardness, wear resistance, and resistance to cold flow.

- If your primary focus is broad chemical resistance in a high-load mechanical part: PEEK-filled PTFE offers an excellent balance, combining mechanical strength with the inertness of PTFE.

By understanding these key differences, you can confidently select the material that delivers the precise performance your design demands.

Summary Table:

| Characteristic | PEEK-Filled PTFE | Virgin PTFE |

|---|---|---|

| Primary Strength | High wear resistance & hardness | Lowest coefficient of friction |

| Best For | Dynamic seals, bearings, high-load parts | Static, low-load, ultra-pure applications |

| Key Limitation | Slightly higher friction, higher cost | Prone to cold flow/deformation under load |

Need a high-performance material solution?

PEEK-filled PTFE from KINTEK combines the chemical resistance of PTFE with the mechanical strength of PEEK, making it ideal for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Whether you require custom prototypes or high-volume production of seals, liners, or labware, our precision manufacturing ensures your components meet the highest standards for durability and performance.

Contact KINTEK today to discuss your specific requirements and get a quote for your project.

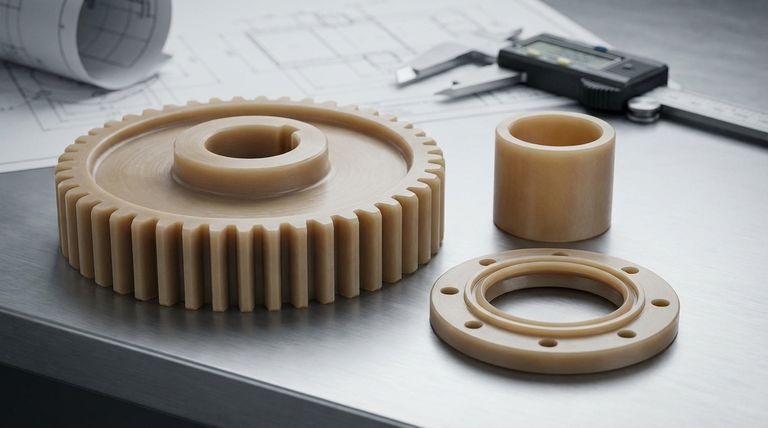

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F