At its core, a torque check is a critical maintenance procedure for PTFE-lined butterfly valves that ensures all fasteners are tightened to the correct specification. This process is essential for maintaining the integrity of the seal, preventing leaks that can arise from operational stresses like vibration and thermal cycling.

The central challenge with PTFE butterfly valves is the material itself. While PTFE offers superior chemical resistance, it is prone to "cold flow" or "creep," where it slowly deforms under constant pressure. Regular torque checks are the primary defense against this, ensuring the clamping force remains consistent and the seal remains intact.

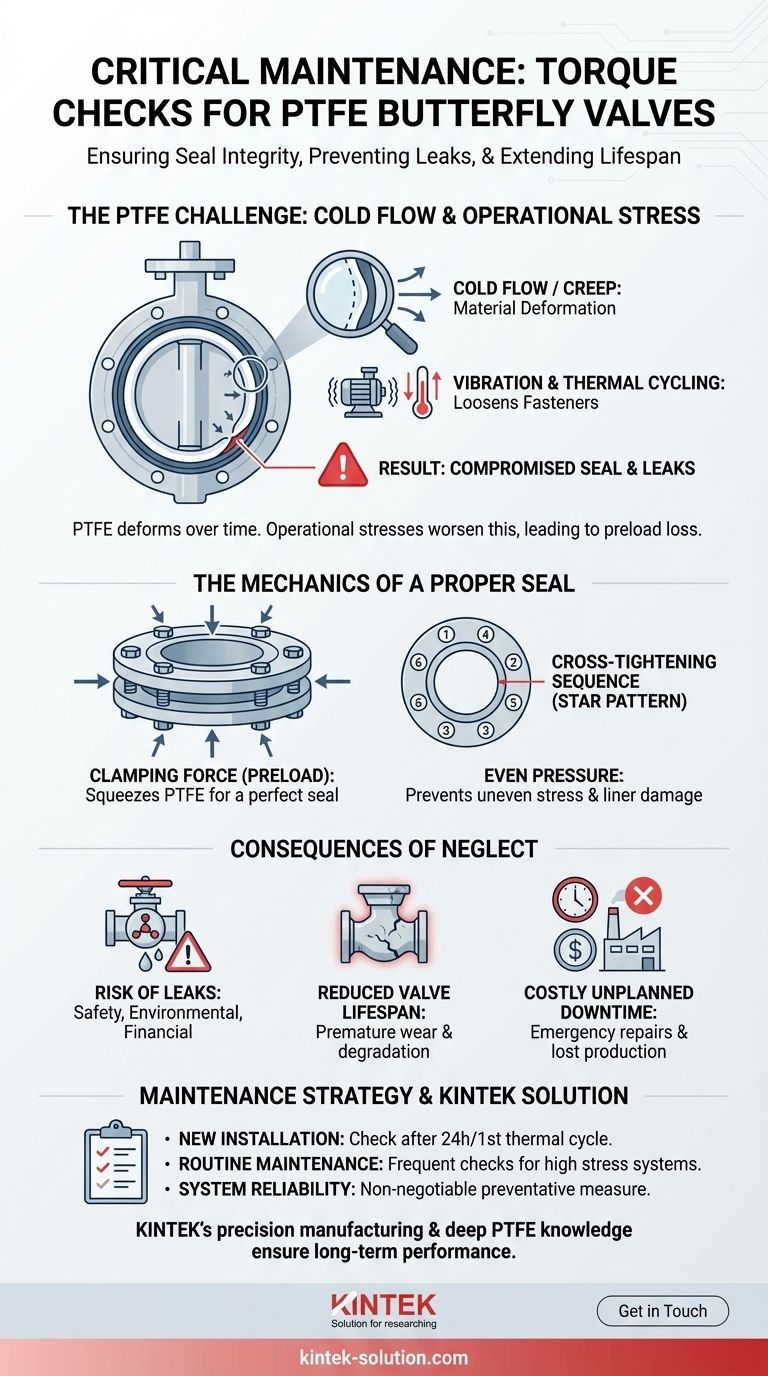

Why Sealing a PTFE Valve is a Unique Challenge

To understand the importance of torque checks, we first need to understand the material at the heart of the valve and the forces acting upon it.

The Benefit of a PTFE Lining

The primary advantage of a PTFE lining is its exceptional chemical resistance. It acts as a protective barrier, shielding the valve's core components from corrosion and damage when handling harsh or abrasive materials.

This non-stick property also ensures smooth operation and prevents material buildup within the valve.

The Concept of "Cold Flow" in PTFE

The most critical factor to understand is that PTFE is a relatively soft material. Under the constant compressive force exerted by flange bolts, the PTFE can slowly deform or "flow" over time, a phenomenon known as cold flow or creep.

This material relaxation causes a loss of bolt preload, which is the tension that holds the seal tight. A torque check is designed specifically to detect and correct this loss of tension.

The Impact of Vibration and Thermal Cycles

Industrial piping systems are rarely static. Vibrations from pumps and motors, along with the thermal cycling (expansion and contraction) caused by temperature changes, can gradually work fasteners loose.

When combined with the natural cold flow of PTFE, these operational stresses significantly increase the risk of a compromised seal and subsequent leaks.

The Mechanics of a Proper Seal

A successful torque check isn't just about making bolts tight; it's about applying a precise and even clamping force to create a durable, leak-proof connection.

What is Clamping Force?

When you apply torque to a bolt, you are creating a specific clamping force, or preload. This is the force that squeezes the valve body between the pipe flanges.

It is this precise amount of force that compresses the PTFE lining just enough to create a perfect seal without damaging the material.

Maintaining Even Pressure

Applying the correct torque is only half the battle. The force must be applied evenly across the entire flange.

This is achieved by following a specific cross-tightening sequence, ensuring that one side of the valve isn't subjected to more stress than another, which could lead to an uneven seal or damage to the lining.

The Consequences of Neglect

Skipping or improperly performing torque checks introduces significant operational risks that far outweigh the cost of the maintenance task itself.

The Inevitable Risk of Leaks

The most immediate consequence of insufficient clamping force is a leak. Given that PTFE valves are often used for corrosive chemicals, a leak poses a serious safety, environmental, and financial risk.

Reduced Valve Lifespan

An improper or uneven seal places undue stress on the PTFE lining and other valve components. This can lead to premature wear, degradation of the material, and ultimately, a shorter operational lifespan for the entire valve assembly.

Costly Unplanned Downtime

A leak forces an immediate, unplanned shutdown of the system for repair. A proactive, scheduled torque check is a minor and predictable maintenance cost, whereas an emergency shutdown results in significant losses from lost production and emergency repair costs.

Making the Right Choice for Your Goal

Integrating torque checks into your maintenance strategy is fundamental to ensuring the long-term reliability of your piping system.

- If your primary focus is a new installation: Always perform a follow-up torque check after the first 24 hours of operation or the first thermal cycle to compensate for the initial settling of the PTFE material.

- If your primary focus is routine maintenance: Schedule periodic checks based on system conditions; systems with high vibration or frequent temperature swings require more frequent attention.

- If your primary focus is overall system reliability: Treat torque checks as a non-negotiable part of your preventative maintenance program to ensure safety and avoid costly failures.

Ultimately, consistent torque management transforms a potential point of failure into a reliable and secure component of your operation.

Summary Table:

| Key Factor | Why It Matters for Torque Checks |

|---|---|

| PTFE Cold Flow | PTFE deforms over time, reducing clamping force; checks restore the proper seal. |

| Vibration & Thermal Cycling | Operational stresses loosen bolts; checks ensure fasteners remain tight. |

| Clamping Force | Correct torque creates the precise pressure needed for a leak-proof seal. |

| Even Pressure Distribution | A cross-tightening sequence prevents damage and ensures a uniform seal. |

Ensure the reliability of your PTFE components with KINTEK's precision manufacturing.

Our deep understanding of PTFE's properties, like cold flow, ensures that the seals, liners, and labware we manufacture for the semiconductor, medical, laboratory, and industrial sectors are built for long-term performance under demanding conditions. We offer custom fabrication from prototypes to high-volume orders, prioritizing the precision that your critical applications demand.

Contact us today to discuss how our PTFE solutions can enhance your system's safety and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability