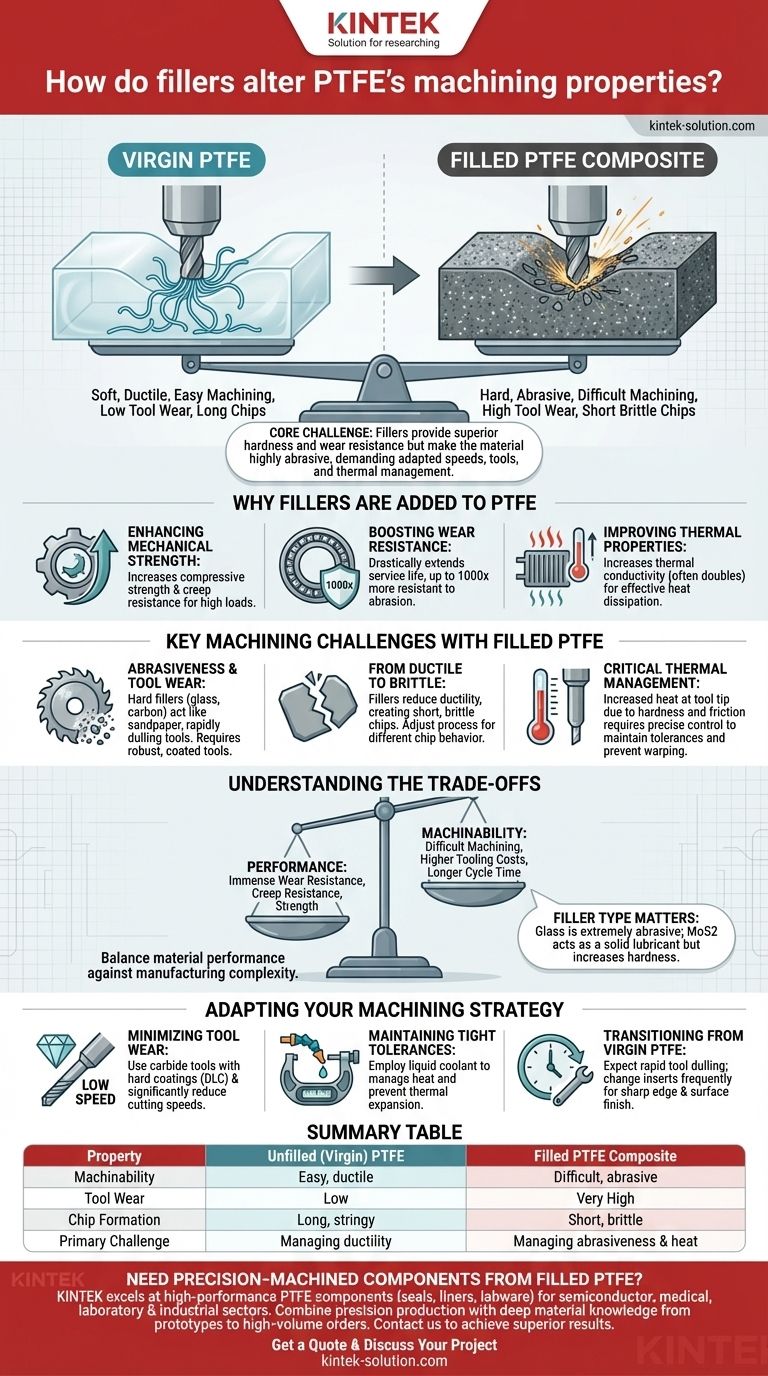

Adding fillers to PTFE fundamentally transforms it from a soft, compliant polymer into a harder, more abrasive composite. This shift dramatically improves its mechanical properties for demanding applications but requires significant adjustments in machining strategy. Machinists must use lower cutting speeds and specialized tooling to manage accelerated tool wear and altered thermal behavior.

The core challenge of machining filled PTFE stems from a single trade-off: the very fillers that provide superior hardness and wear resistance also make the material highly abrasive, demanding adapted speeds, tools, and thermal management to prevent rapid tool failure and maintain dimensional accuracy.

Why Fillers are Added to PTFE

Unfilled, or "virgin," PTFE is known for its low friction and chemical inertness, but it is mechanically soft. Fillers are introduced to create a composite material with enhanced engineering properties.

Enhancing Mechanical Strength

Fillers like carbon, bronze, and glass fibers significantly increase the compressive strength and creep resistance of PTFE. This allows the material to withstand higher loads and maintain its shape over time, which is critical in components like seals and bearings.

Boosting Wear Resistance

The most dramatic improvement is in wear and abrasion resistance. Some studies show that filled PTFE can be up to 1000 times more resistant to abrasion than its unfilled counterpart, drastically extending the service life of dynamic components.

Improving Thermal Properties

Fillers increase the thermal conductivity of PTFE, often doubling it. This allows the material to dissipate heat more effectively, which is crucial for reducing surface temperatures in high-speed, high-pressure applications and improving overall durability.

Key Machining Challenges with Filled PTFE

The properties that make filled PTFE a superior engineering material also make it more challenging to machine compared to virgin PTFE.

The Problem of Abrasiveness and Tool Wear

Fillers, particularly glass and carbon, are highly abrasive. During machining, these hard particles act like fine sandpaper against the cutting edge of the tool, causing it to dull very quickly. This necessitates the use of more robust and often more expensive coated tools.

From Ductile to Brittle: Managing Chip Formation

Virgin PTFE is ductile and tends to produce long, continuous, stringy chips during machining. In contrast, the fillers in filled PTFE reduce its ductility, causing it to produce shorter, more brittle chips. Machinists must adjust their process to account for this different chip behavior.

The Critical Role of Thermal Management

While filled PTFE has better thermal conductivity, the increased hardness and friction during cutting can generate more heat at the tool tip. This, combined with a modified coefficient of thermal expansion, means that precise thermal control is essential to hold tight tolerances and prevent part warping.

Understanding the Trade-offs

Choosing to use and machine filled PTFE involves balancing material performance against manufacturing complexity.

Performance vs. Machinability

The primary trade-off is clear: you gain immense improvements in wear resistance, creep resistance, and strength at the cost of significantly more difficult and demanding machining. The material is harder on tooling and less forgiving of incorrect parameters.

Cost of Tooling and Cycle Time

The abrasive nature of filled PTFE leads to shorter tool life, increasing tooling costs. To mitigate this, machinists must reduce cutting speeds, which in turn increases the cycle time for each part and raises production costs.

Filler Type Matters

Different fillers create different machining challenges. Glass is extremely abrasive, while fillers like molybdenum disulfide (MoS2) can act as a solid lubricant, slightly reducing friction at the tool tip even as they increase hardness.

Adapting Your Machining Strategy

Success with filled PTFE requires a deliberate approach that acknowledges its composite nature. Use the following guidelines to tailor your process.

- If your primary focus is minimizing tool wear: Use carbide tools with specialized, hard coatings (like diamond-like carbon) and reduce cutting speeds significantly compared to virgin PTFE.

- If your primary focus is maintaining tight tolerances: Employ a liquid coolant to manage heat at the cutting interface and prevent thermal expansion from affecting dimensional accuracy.

- If you are transitioning from virgin PTFE: Expect rapid tool dulling and be prepared to change inserts or tools far more frequently to maintain a sharp cutting edge and good surface finish.

Ultimately, treating filled PTFE not as a plastic but as a composite abrasive is the key to machining it successfully.

Summary Table:

| Property | Unfilled (Virgin) PTFE | Filled PTFE Composite |

|---|---|---|

| Machinability | Easy, ductile | Difficult, abrasive |

| Tool Wear | Low | Very High |

| Chip Formation | Long, stringy | Short, brittle |

| Primary Challenge | Managing ductility | Managing abrasiveness & heat |

Need precision-machined components from filled PTFE?

Machining filled PTFE composites requires specialized expertise to manage extreme abrasiveness and maintain dimensional accuracy. KINTEK excels at manufacturing high-performance PTFE components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors.

We combine precision production with deep material knowledge to navigate the challenges of filled PTFE, from custom prototypes to high-volume orders.

Contact us today to discuss your project and achieve superior results with your most demanding polymer composites.

Get a Quote & Discuss Your Project

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support