In short, PTFE lined check valves are ideal for commercial environments because of their near-total immunity to chemical corrosion. This allows them to reliably manage highly aggressive fluids, like strong acids and alkalis, without degrading, which ensures the safety, purity, and longevity of the entire fluid system.

The core value of a PTFE lining is that it creates an inert, non-reactive barrier between the valve's metal body and the process fluid. This isolates the structural components from corrosive attack, guaranteeing system integrity and preventing contamination in sensitive applications.

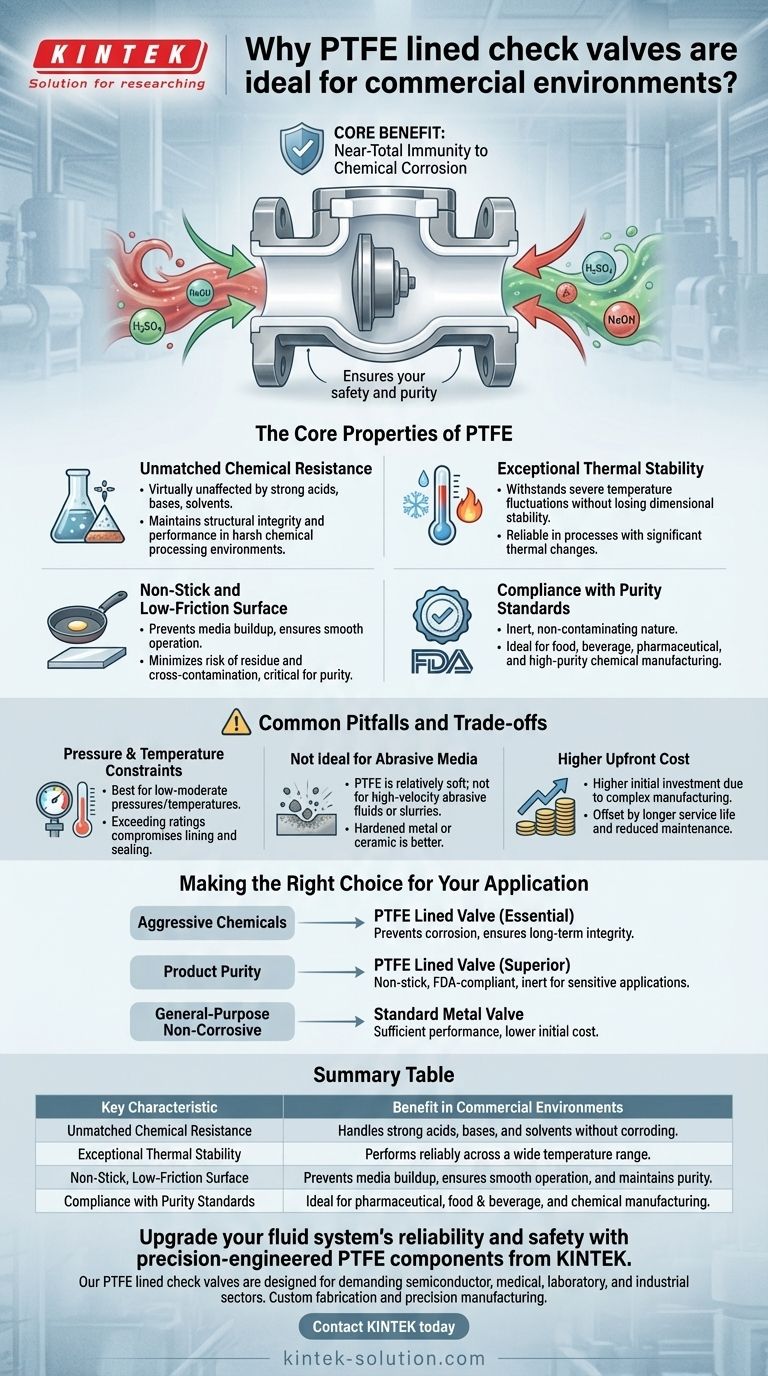

The Core Properties of PTFE

The effectiveness of PTFE (Polytetrafluoroethylene) in demanding commercial settings stems from a unique combination of physical and chemical characteristics.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. It is virtually unaffected by strong acids, bases, solvents, and other aggressive agents that would quickly corrode even specialized metal alloys.

This resistance ensures the check valve maintains its structural integrity and performance over a long service life, even in the harshest chemical processing environments.

Exceptional Thermal Stability

PTFE maintains its key properties across a wide temperature range. It can withstand severe operating temperatures, both high and low, without losing its dimensional stability or chemical resistance.

This makes PTFE lined valves a reliable choice for processes that involve significant temperature fluctuations.

Non-Stick and Low-Friction Surface

The material is famous for its non-stick, low-friction surface. In a check valve, this prevents process media from adhering to internal components, ensuring smooth and reliable valve operation.

This property is also critical for maintaining fluid purity, as it minimizes the risk of residue buildup and cross-contamination.

Compliance with Purity Standards

Because of its inertness and non-contaminating nature, PTFE is often compliant with strict industry standards, including those from the FDA for food and beverage applications.

This makes it the material of choice for industries where product purity is non-negotiable, such as pharmaceutical production, food processing, and high-purity chemical manufacturing.

Common Pitfalls and Trade-offs

While highly effective, PTFE lined valves are a specialized solution. Understanding their limitations is key to proper application.

Pressure and Temperature Constraints

Although PTFE has excellent thermal stability, specific valve designs are best suited for systems operating at relatively low to moderate pressures and temperatures.

Exceeding the manufacturer's specified pressure-temperature rating can compromise the integrity of the lining and the valve's sealing capability.

Not Ideal for Abrasive Media

PTFE is a relatively soft material compared to metals. It is not designed for applications involving high-velocity fluids containing abrasive particles or slurries, as this can physically wear away the lining over time.

In such cases, a valve made from hardened metal or featuring a ceramic lining would be a more appropriate choice.

Higher Upfront Cost

PTFE lined valves typically have a higher initial cost compared to standard all-metal valves. This is due to the more complex manufacturing process required to bond the lining to the valve body.

However, this cost is frequently offset by a significantly longer service life, reduced maintenance, and the prevention of costly failures in corrosive service.

Making the Right Choice for Your Application

Selecting the correct valve material is a critical decision that directly impacts system reliability and safety.

- If your primary focus is handling aggressive chemicals: A PTFE lined valve is essential for preventing corrosion and ensuring long-term system integrity.

- If your primary focus is ensuring product purity: The non-stick, inert, and FDA-compliant nature of PTFE makes it the superior choice for food, beverage, and pharmaceutical applications.

- If your primary focus is a general-purpose, non-corrosive system: A standard stainless steel or other suitable metal valve may provide sufficient performance at a lower initial cost.

Ultimately, choosing a PTFE lined check valve is an investment in reliability and safety for any system handling corrosive or high-purity fluids.

Summary Table:

| Key Characteristic | Benefit in Commercial Environments |

|---|---|

| Unmatched Chemical Resistance | Handles strong acids, bases, and solvents without corroding. |

| Exceptional Thermal Stability | Performs reliably across a wide temperature range. |

| Non-Stick, Low-Friction Surface | Prevents media buildup, ensures smooth operation, and maintains purity. |

| Compliance with Purity Standards | Ideal for pharmaceutical, food & beverage, and chemical manufacturing. |

Upgrade your fluid system's reliability and safety with precision-engineered PTFE components from KINTEK.

Our PTFE lined check valves are designed for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision manufacturing and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Invest in long-term performance and prevent costly downtime. Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments