For selecting the right PTFE valve, direct support is available from dedicated teams of professionals who specialize in high-purity fluid handling. These experts help analyze your specific liquid transfer requirements to determine the ideal valve design and size for your application.

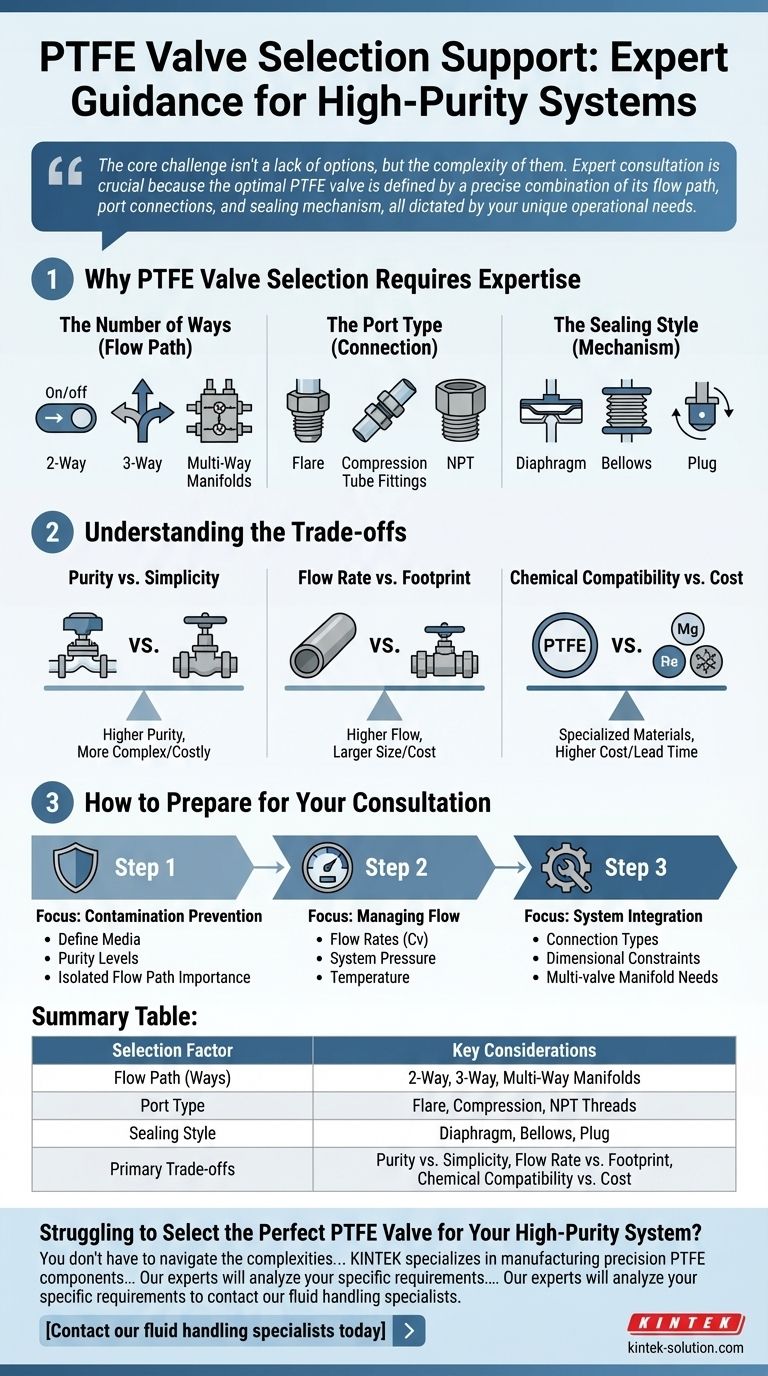

The core challenge isn't a lack of options, but the complexity of them. Expert consultation is crucial because the optimal PTFE valve is defined by a precise combination of its flow path, port connections, and sealing mechanism, all dictated by your unique operational needs.

Why PTFE Valve Selection Requires Expertise

Choosing a PTFE valve is not a one-size-fits-all process. The ideal component for one high-purity system could be a point of failure in another. The selection process is a technical assessment of your system's specific demands.

The Number of Ways (Flow Path)

A valve's "ways" determine how it directs fluid. A 2-Way valve provides simple on/off control. A 3-Way valve can divert flow between two paths or mix two inputs. For more complex routing, manifolded multi-way designs integrate multiple valve functions into a single block.

The Port Type (Connection)

The port type dictates how the valve connects to your tubing. Flare ports are common in high-purity semiconductor applications for their secure, clean seal. Compression tube fittings offer a robust mechanical grip, while NPT (National Pipe Taper) ports are a standard for threaded connections.

The Sealing Style (Mechanism)

The internal sealing mechanism is critical for performance and purity. A diaphragm seal isolates the fluid path from the valve's actuator, offering superior purity. A bellows seal provides a similar high-purity barrier with a long cycle life. A plug seal is a simpler, more compact design for less critical applications.

Understanding the Trade-offs

Every design choice involves a compromise. Understanding these trade-offs is key to having a productive conversation with an application specialist and ensuring you get the right valve, not just an available one.

Purity vs. Simplicity

Valves with diaphragm or bellows seals offer the highest level of purity by completely isolating the media from the valve's mechanical parts. However, this often results in a more complex and costly design compared to simpler plug-style valves.

Flow Rate vs. Footprint

Larger orifice sizes and port connections allow for higher flow rates but increase the overall size and cost of the valve. In systems where space is at a premium, a more compact valve with a lower flow rate might be the necessary choice.

Chemical Compatibility vs. Cost

While PTFE offers excellent chemical resistance, specialized applications may require other high-performance materials for certain components. These material choices directly impact the valve's cost and lead time.

How to Prepare for Your Consultation

To make the most of expert support, you must first define your core requirements.

- If your primary focus is preventing contamination: Be prepared to discuss your media, required purity levels, and the importance of an isolated flow path.

- If your primary focus is managing flow: Know your required flow rates (Cv), system pressure, and temperature to properly size the valve's orifice and ports.

- If your primary focus is system integration: Have clear specifications for your connection types, dimensional constraints, and whether a multi-valve manifold could simplify your design.

Equipped with this information, you can collaborate effectively with specialists to select a valve that performs reliably for its intended lifespan.

Summary Table:

| Selection Factor | Key Considerations |

|---|---|

| Flow Path (Ways) | 2-Way (On/Off), 3-Way (Diversion/Mixing), Multi-Way Manifolds |

| Port Type | Flare Fittings, Compression Fittings, NPT Threads |

| Sealing Style | Diaphragm (Highest Purity), Bellows (Long Life), Plug (Compact) |

| Primary Trade-offs | Purity vs. Simplicity, Flow Rate vs. Footprint, Chemical Compatibility vs. Cost |

Struggling to Select the Perfect PTFE Valve for Your High-Purity System?

You don't have to navigate the complexities of flow path, port connections, and sealing mechanisms alone. KINTEK specializes in manufacturing precision PTFE components, including custom valves, for the semiconductor, medical, laboratory, and industrial sectors.

Our experts will analyze your specific requirements for contamination control, flow management, and system integration to recommend the ideal valve design and size. We provide custom fabrication from prototypes to high-volume orders, ensuring optimal performance and reliability.

Contact our fluid handling specialists today for a personalized consultation and let us help you solve your unique application challenge.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency