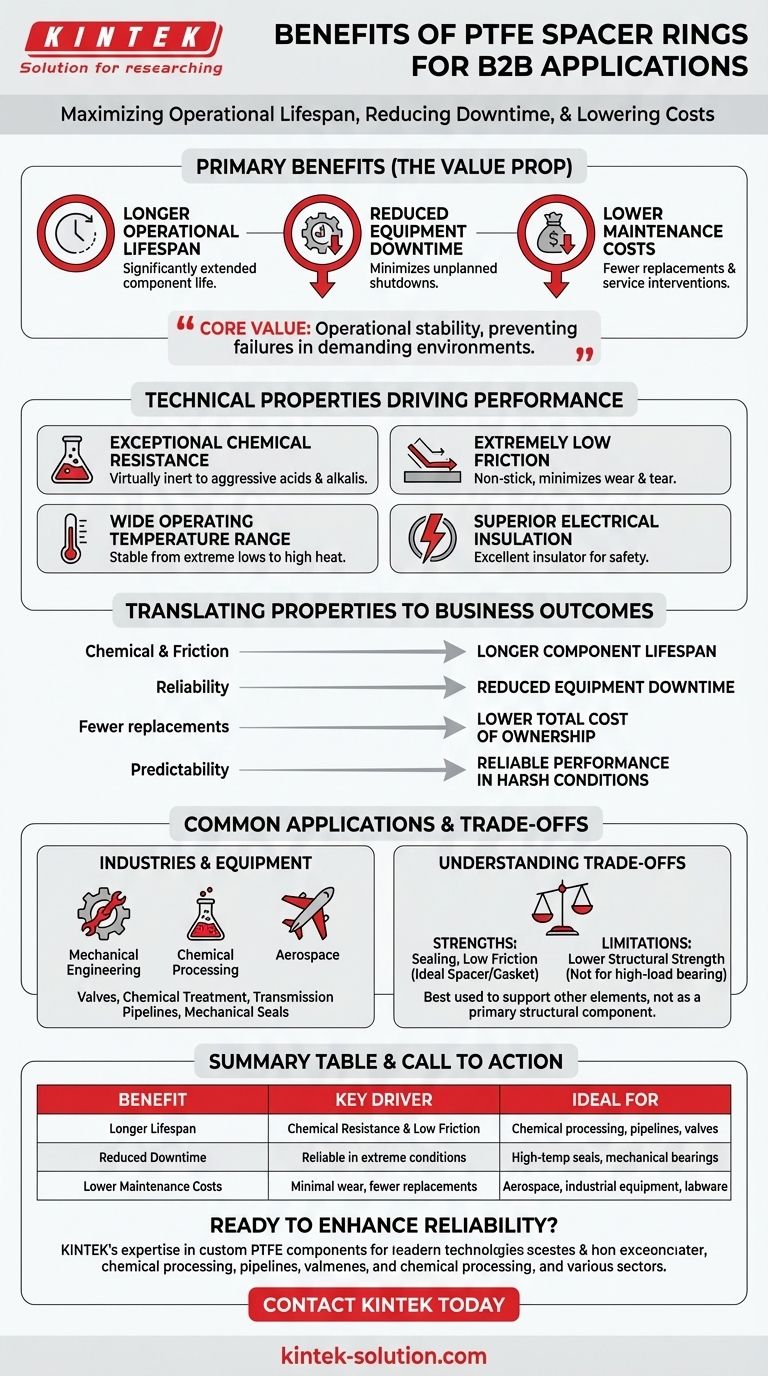

The primary benefits of PTFE spacer rings are a longer operational lifespan, significantly reduced equipment downtime, and lower overall maintenance costs. These advantages stem from their ability to deliver exceptionally reliable performance, especially in chemically aggressive and high-temperature environments.

The core value of PTFE spacer rings is not just the component itself, but the operational stability it provides. Its unique material properties directly translate into tangible business outcomes by preventing failures in the most demanding industrial applications.

The Technical Properties Driving the Benefits

The value of PTFE spacer rings comes from a unique combination of inherent material characteristics. Understanding these properties explains why they are such a reliable choice.

Exceptional Chemical Resistance

PTFE is virtually inert to most industrial chemicals, including aggressive acids and alkalis. This chemical stability prevents the material from degrading or corroding over time.

This makes PTFE rings ideal for seals in equipment like chemical pipelines, reaction kettles, and storage tanks, where exposure to corrosive substances is constant.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. Its non-stick surface minimizes resistance between moving parts.

This property is critical in applications like bearings, seals, and piston rings, where it reduces wear and tear, thereby extending the life of both the ring and the equipment it protects.

Wide Operating Temperature Range

PTFE maintains its integrity and performance across a vast temperature spectrum, from extreme lows to continuous high operating temperatures.

This thermal stability ensures reliable sealing and spacing in environments where other materials would become brittle or deform, guaranteeing consistent performance.

Superior Electrical Insulation

In addition to its mechanical properties, PTFE is an excellent electrical insulator. This adds value in applications where preventing electrical conductivity is a critical safety or operational requirement.

Translating Properties into Business Value

These technical attributes are not just abstract data points; they create clear and measurable advantages for any operation.

Longer Component Lifespan

Because PTFE resists chemical attack and minimizes frictional wear, components simply last longer. This reduces the frequency of replacement cycles.

Reduced Equipment Downtime

Reliable components that don't fail unexpectedly are the cornerstone of operational efficiency. Using PTFE in critical seals and joints minimizes unplanned shutdowns for repairs.

Lower Maintenance Costs

Fewer component replacements and less frequent service interventions directly lead to a lower total cost of ownership for the equipment.

Reliable Performance in Harsh Conditions

The ultimate benefit is predictability. PTFE provides peace of mind that a component will perform its function consistently, even when subjected to corrosive chemicals, high temperatures, and mechanical stress.

Common Applications Across Industries

The unique benefits of PTFE make it a preferred material in several demanding sectors.

Key Industrial Uses

PTFE spacer rings are widely adopted in mechanical engineering, chemical processing, and aerospace. Their reliability is proven in these high-stakes fields.

Specific Equipment Examples

You will find these components providing critical sealing and spacing in valves, chemical treatment equipment, transmission pipelines, and various high-performance mechanical seals.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Its primary strengths are in sealing and low-friction applications, not high-load structural roles.

Consider Mechanical Strength

PTFE is a relatively soft material with lower tensile strength and resistance to deformation under load (creep) compared to high-performance polymers like PEEK.

Best Used as a Sealing Component

It excels as a spacer, gasket, or backup ring that supports another sealing element. It is not typically used for components that bear significant structural or mechanical loads on their own.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your primary operational goal.

- If your primary focus is reliability in corrosive environments: PTFE is an ideal choice due to its unmatched chemical inertness.

- If your primary focus is reducing friction and wear in moving parts: PTFE's low friction coefficient directly translates to longer component life and lower maintenance needs.

- If your primary focus is performance across extreme temperatures: PTFE's wide operating range ensures stability and predictable performance where other materials would fail.

Ultimately, choosing PTFE spacer rings is a strategic decision for achieving operational excellence in demanding industrial applications.

Summary Table:

| Benefit | Key Driver | Ideal For |

|---|---|---|

| Longer Lifespan | Exceptional chemical resistance & low friction | Chemical processing, pipelines, valves |

| Reduced Downtime | Reliable performance in extreme conditions | High-temperature seals, mechanical bearings |

| Lower Maintenance Costs | Minimal wear and tear, fewer replacements | Aerospace, industrial equipment, labware |

Ready to enhance your equipment's reliability with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, spacer rings, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get components that deliver superior chemical resistance, reduce downtime, and lower your total cost of ownership.

Contact us today to discuss your specific application needs and get a solution tailored to your operational challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance