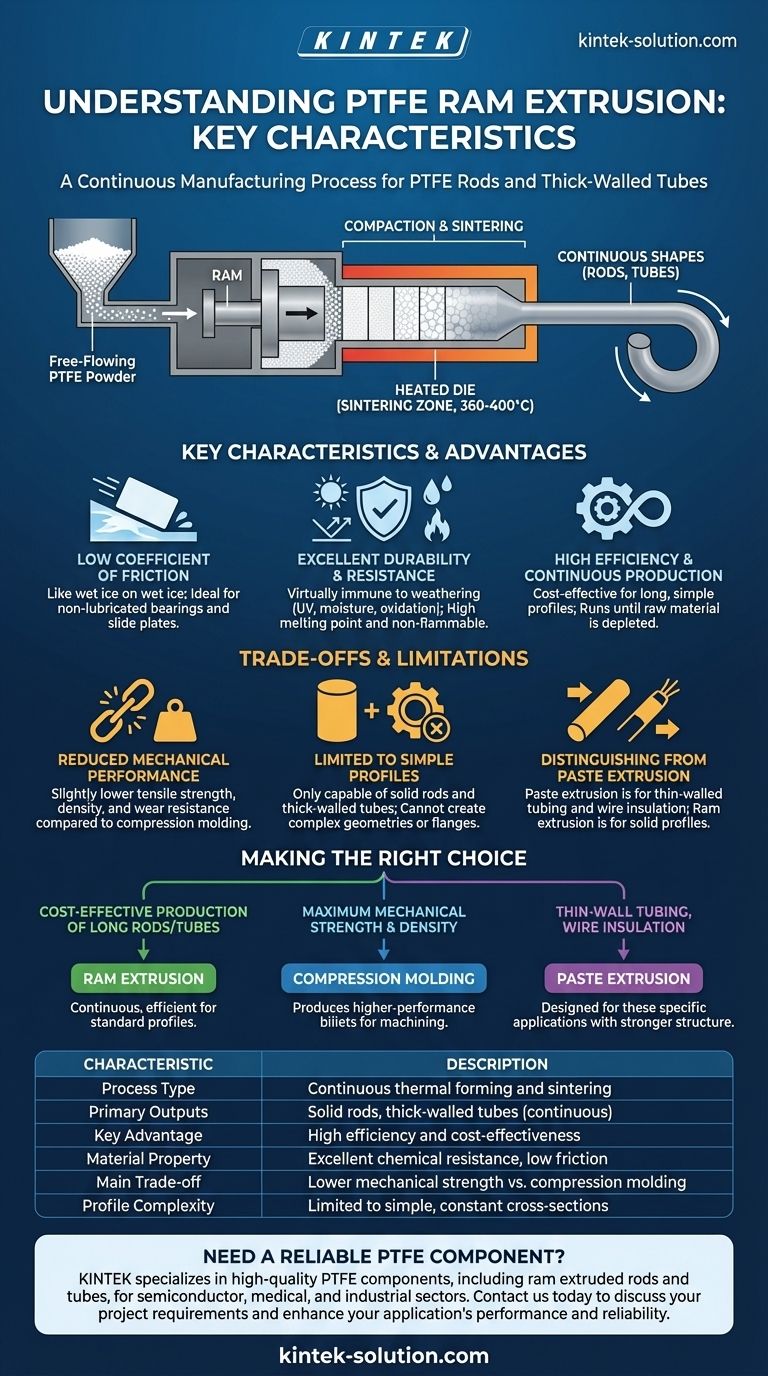

In essence, PTFE ram extrusion is a continuous manufacturing process that uses a reciprocating ram to compact free-flowing PTFE powder and push it through a heated die. This method simultaneously forms and sinters the material, making it highly efficient for producing long, simple shapes like solid rods and thick-walled tubes.

The central trade-off of ram extrusion is efficiency versus performance. While it is an excellent method for cost-effective, continuous production of standard PTFE profiles, the resulting parts typically exhibit lower mechanical properties than those produced by batch processes like compression molding.

The Mechanics of Ram Extrusion

To understand the characteristics of its output, you must first understand the process itself. Ram extrusion is a unique thermal forming process governed by a few key principles.

The Material: Free-Flowing Powder

The process begins with a specific grade of PTFE known as free-flowing or pre-sintered resin. Unlike the fine powders used in other methods, this granular material flows evenly into the machine without the need for processing aids or lubricants.

The Process: Compaction and Sintering

A hydraulic or pneumatic ram operates in a cycle, compacting a small charge of powder on each forward stroke. This action pushes the entire column of material incrementally through a long, heated die tube.

The die is heated to the sintering temperature of PTFE (around 360-400°C). As the compacted powder moves through this zone, the particles fuse together, creating a solid, homogenous profile that exits the machine.

The Output: Continuous Shapes

The primary advantage of this method is its ability to produce continuous, theoretically unending lengths of simple cylindrical profiles. The process runs until the machine is out of raw material, allowing for the creation of very long rods and tubes that are impractical with other methods.

Key Characteristics of Ram Extruded PTFE

The products made via ram extrusion inherit the fundamental properties of PTFE, but the manufacturing method imparts its own distinct qualities.

Low Coefficient of Friction

Extruded PTFE rods and tubes possess an exceptionally low coefficient of friction. This property, often compared to wet ice on wet ice, makes them ideal for bearings, slide plates, and other low-friction, non-lubricated applications.

Excellent Durability and Resistance

Like all PTFE, ram extruded parts are highly durable. They are virtually immune to weathering, including degradation from UV light, oxidation, and moisture.

They also exhibit a high melting point and are non-flammable, making them suitable for demanding outdoor, industrial, and long-term applications.

Understanding the Trade-offs

No single manufacturing process is perfect for every application. Objectivity requires acknowledging the limitations inherent in ram extrusion.

Reduced Mechanical Performance

The most significant trade-off is mechanical strength. Compared to parts made via compression molding, ram extruded profiles often have slightly lower tensile strength, density, and wear resistance.

The cyclical compaction can introduce minor variations in density along the length of the part, making it less suitable for the most critical, high-stress mechanical components.

Limited to Simple Profiles

Ram extrusion is only capable of producing simple, constant cross-section shapes. It is used exclusively for solid rods and thick-walled tubing and cannot create complex geometries, flanges, or intricate parts.

Distinguishing from Paste Extrusion

It is critical not to confuse ram extrusion with paste extrusion. Paste extrusion mixes fine PTFE powder with a lubricant to form a paste, which is then forced through a die to create thin-walled products like wire insulation or chemical hoses. This process creates a stronger, fibrillated molecular structure after the lubricant is baked off.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process is critical to achieving your desired balance of cost, performance, and form factor.

- If your primary focus is cost-effective production of long rods or thick-walled tubes: Ram extrusion is the ideal choice due to its continuous, efficient nature.

- If your primary focus is maximum mechanical strength and material density: You should specify compression molded PTFE, which produces higher-performance billets for machining.

- If your primary focus is creating thin-walled tubing, wire insulation, or flexible hose liners: PTFE paste extrusion is the correct process, as it is designed for these specific applications.

Ultimately, understanding these distinct characteristics allows you to select the PTFE manufacturing process that precisely aligns with your project's performance and economic requirements.

Summary Table:

| Characteristic | Description |

|---|---|

| Process Type | Continuous thermal forming and sintering |

| Primary Outputs | Solid rods, thick-walled tubes (continuous lengths) |

| Key Advantage | High efficiency and cost-effectiveness for simple profiles |

| Material Property | Excellent chemical resistance, low friction, non-flammable |

| Main Trade-off | Lower mechanical strength vs. compression molding |

| Profile Complexity | Limited to simple, constant cross-sections |

Need a reliable PTFE component for your application?

At KINTEK, we specialize in manufacturing high-quality PTFE components, including ram extruded rods and tubes, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right balance of performance and cost-efficiency for your specific needs.

Whether you require a standard profile or a custom fabrication from prototype to high-volume production, we prioritize precision and durability.

Contact us today to discuss your project requirements and discover how KINTEK's PTFE solutions can enhance your application's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments