The primary disadvantages of pure Polytetrafluoroethylene (PTFE) are its poor mechanical properties, specifically its low resistance to creep (deformation under load) and abrasion. These weaknesses, combined with significant manufacturing challenges and an inability to be easily bonded, limit its use in structural or high-wear applications without reinforcement.

While prized for its extreme chemical inertness and low friction, pure PTFE is fundamentally a soft material. Its key drawbacks stem from a lack of structural integrity and the complex, costly processes required to manufacture parts from it.

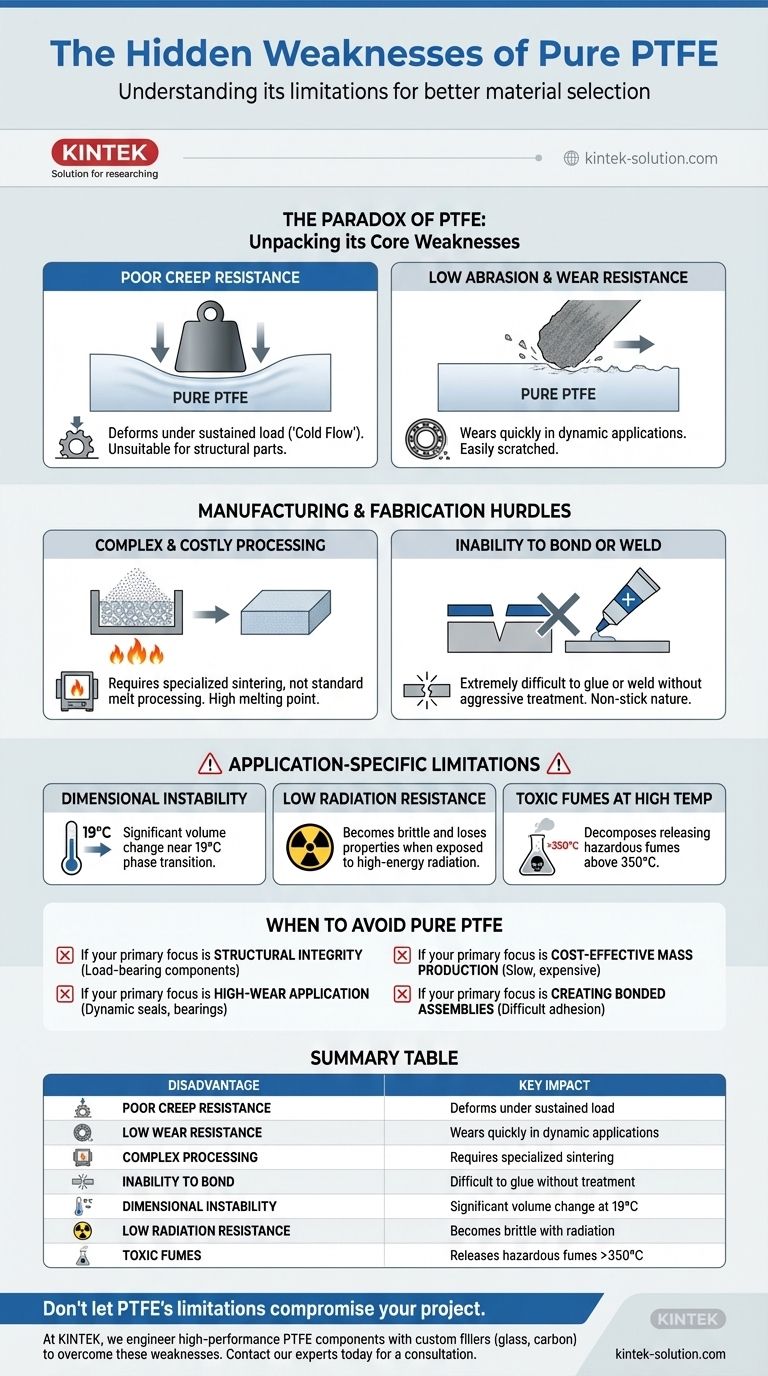

The Paradox of PTFE: Unpacking its Core Weaknesses

PTFE's most famous qualities—its slipperiness and chemical resistance—are also the source of some of its biggest challenges. Understanding these limitations is critical for successful material selection.

Poor Creep Resistance

Under a sustained load, even at room temperature, pure PTFE will slowly and permanently deform. This phenomenon, known as creep or "cold flow," makes it unsuitable for components that must hold a precise shape under constant pressure, such as structural supports or high-pressure seals.

Low Abrasion and Wear Resistance

Despite having the lowest coefficient of friction of any solid, pure PTFE is not highly resistant to wear. It is a relatively soft polymer that can be easily scratched and abraded, leading to rapid failure in dynamic applications like bearings or sliding parts that experience friction.

Manufacturing and Fabrication Hurdles

Working with PTFE is fundamentally different from working with common plastics like nylon or polycarbonate, which introduces significant cost and design constraints.

Complex and Costly Processing

PTFE has an extremely high melting point and viscosity, meaning it cannot be processed using conventional melt techniques like injection molding or extrusion. Instead, it must be manufactured using a specialized and more expensive sintering process, similar to how powdered metals are formed.

Inability to Bond or Weld

The famous non-stick property of PTFE means it is extremely difficult to bond to other materials—or even to itself—using conventional cements or adhesives. Achieving a strong bond requires aggressive and costly surface preparation techniques like chemical etching.

Application-Specific Limitations

Beyond its core mechanical and manufacturing issues, several other properties can disqualify PTFE from certain applications.

Dimensional Instability

PTFE undergoes a phase transition at 19°C (66°F). This causes a significant change in volume, which can compromise the integrity and precision of components designed for tight tolerances that operate near this temperature.

Low Radiation Resistance

Compared to other polymers, PTFE has very poor resistance to high-energy radiation. The material's polymer chains are easily broken down by radiation, causing it to become brittle and lose its useful properties.

Production of Toxic Fumes

While stable up to 260°C (500°F), PTFE will begin to decompose at very high temperatures (above 350°C). This decomposition can release toxic and corrosive fumes, posing a significant safety hazard in certain environments.

When to Avoid Pure PTFE

Making the right material choice requires matching the material's profile to your primary goal. Pure, unfilled PTFE is often the wrong choice in specific scenarios.

- If your primary focus is structural integrity: Pure PTFE is unsuitable for any load-bearing component due to its profound tendency to creep and deform under pressure.

- If your primary focus is a high-wear application: The material will wear down quickly in dynamic seals or bearings unless it is reinforced with fillers like glass, carbon, or bronze.

- If your primary focus is cost-effective mass production: The specialized sintering process makes PTFE more expensive and slower to manufacture than common thermoplastics.

- If your primary focus is creating bonded assemblies: Its inherent non-stick nature makes it exceptionally difficult to glue, requiring specialized and costly surface treatments for adhesion.

Understanding these limitations is the key to leveraging PTFE's remarkable strengths without falling victim to its inherent weaknesses.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Poor Creep Resistance | Deforms under sustained load, unsuitable for structural parts. |

| Low Abrasion/Wear Resistance | Wears quickly in dynamic applications like bearings or seals. |

| Complex & Costly Processing | Requires specialized sintering, not standard melt processing. |

| Inability to Bond Easily | Difficult to glue or weld without aggressive surface treatment. |

| Dimensional Instability | Significant volume change near its 19°C phase transition. |

| Low Radiation Resistance | Becomes brittle when exposed to high-energy radiation. |

| Toxic Fumes at High Temp | Decomposes above 350°C, releasing hazardous fumes. |

Don't let PTFE's limitations compromise your project.

At KINTEK, we specialize in manufacturing high-performance PTFE components (seals, liners, labware, etc.) that overcome these weaknesses. We engineer solutions with custom fillers (like glass or carbon) to enhance creep and wear resistance, and our precision production expertise ensures your parts meet exact specifications—from prototypes to high-volume orders.

Let us help you select or fabricate the right PTFE material for your needs in the semiconductor, medical, laboratory, or industrial sectors.

Contact our experts today for a consultation to discuss your application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers

- What is Teflon and what is its chemical name? Unpacking the Science of PTFE

- How was PTFE discovered and developed? From Lab Accident to Essential High-Performance Polymer