A PTFE envelope gasket is a composite seal designed to combine the exceptional chemical resistance of Polytetrafluoroethylene (PTFE) with the mechanical strength and resilience of a different core material. The gasket consists of a PTFE "envelope" that encases an inner ring, creating a seal that is both chemically inert and physically robust.

The central concept is that a PTFE envelope gasket is a two-part system. It uses a chemically inert PTFE outer layer to protect a mechanically resilient inner core, delivering a sealing solution that excels in corrosive environments where a standard gasket would fail.

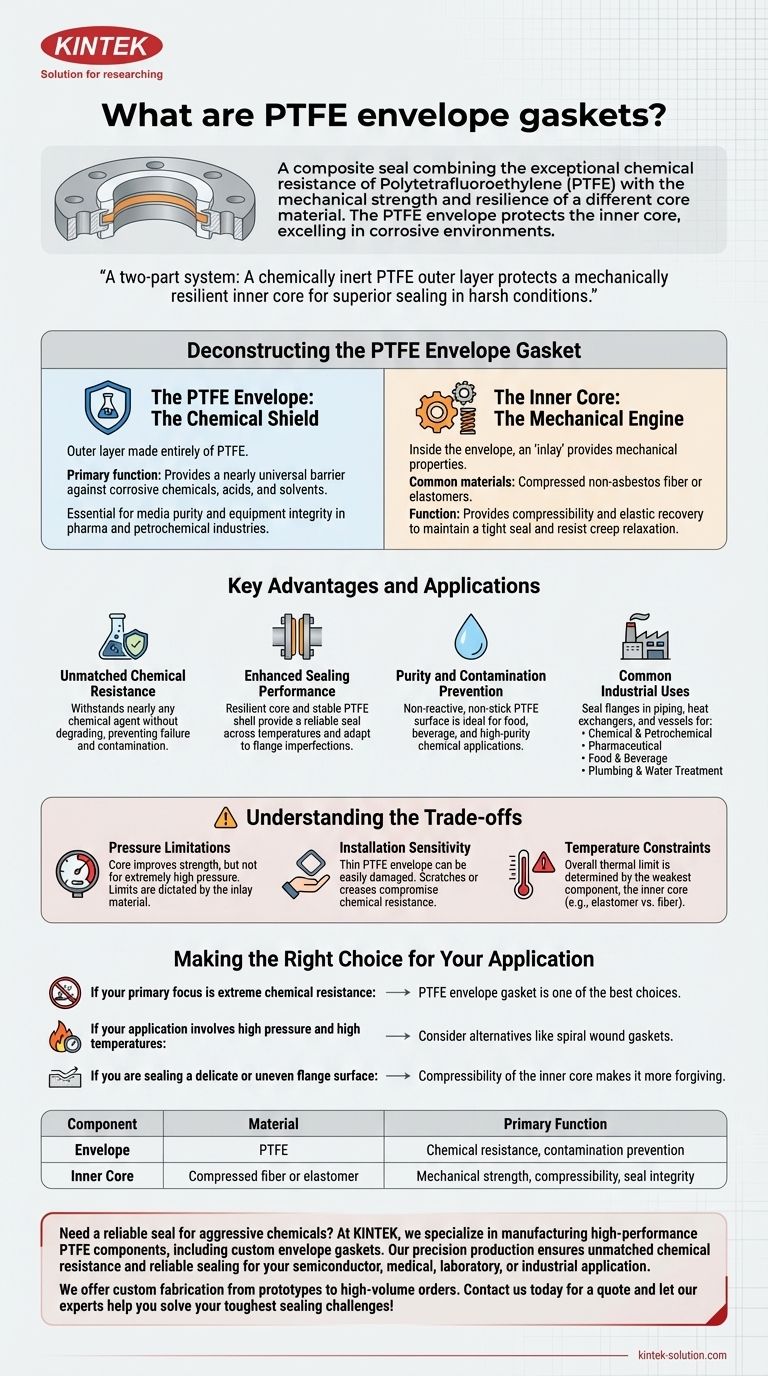

Deconstructing the PTFE Envelope Gasket

To understand why this design is so effective, we must look at its two distinct components and the roles they play.

The PTFE Envelope: The Chemical Shield

The outer layer is a thin envelope made entirely of PTFE, a fluoropolymer known for its remarkable properties. This envelope is the only part of the gasket that comes into contact with the process media.

Its primary function is to provide a nearly universal barrier against corrosive chemicals, acids, and solvents. This makes the gasket suitable for industries like pharmaceuticals and petrochemicals where media purity and equipment integrity are critical.

The Inner Core: The Mechanical Engine

Inside the PTFE envelope sits a core material, often called an inlay. This core provides the mechanical properties that pure PTFE lacks, such as compressibility and elastic recovery.

Common core materials include compressed non-asbestos fiber or various elastomers. This inner ring provides the physical force required to create and maintain a tight seal between two flange faces, preventing leaks and resisting creep relaxation over time.

Key Advantages and Applications

The dual-material design gives PTFE envelope gaskets a unique set of advantages that make them the preferred choice in specific scenarios.

Unmatched Chemical Resistance

The primary benefit is the gasket's ability to withstand nearly any chemical agent without degrading. This prevents both gasket failure and contamination of the product being processed.

Enhanced Sealing Performance

By combining a resilient core with a stable PTFE shell, these gaskets provide a reliable seal across a wide temperature range. The core material ensures the gasket can adapt to flange surface imperfections and maintain sealing pressure.

Purity and Contamination Prevention

Because the PTFE surface is non-reactive and non-stick, it is ideal for applications where product purity is paramount. This includes food processing, beverage production, and the manufacturing of high-purity chemicals.

Common Industrial Uses

These gaskets are frequently specified to seal flanges on piping, heat exchangers, and vessel openings in industries such as:

- Chemical and Petrochemical Processing

- Pharmaceutical Manufacturing

- Food and Beverage Production

- Plumbing and Water Treatment

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are a specialized solution with specific limitations that must be considered.

Pressure Limitations

The primary trade-off is pressure handling. While the core improves mechanical strength, these gaskets are generally not intended for extremely high-pressure applications. The operational limits are largely dictated by the inlay material.

Installation Sensitivity

The PTFE envelope is relatively thin and can be damaged if not handled and installed with care. A scratch or crease in the envelope can create a leak path, completely compromising the seal's chemical resistance.

Temperature Constraints

While PTFE has a broad service temperature range, the gasket's overall thermal limit is determined by its weakest component—the inner core. An elastomeric core, for example, will have a much lower maximum temperature rating than a compressed fiber core.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching its properties to your operational demands.

- If your primary focus is extreme chemical resistance: A PTFE envelope gasket is one of the best choices available, protecting your system from corrosive media.

- If your application involves high pressure and high temperatures: You may need to consider an alternative like a spiral wound gasket, as this is a common limitation for envelope designs.

- If you are sealing a delicate or uneven flange surface: The compressibility of the inner core makes this gasket type more forgiving than a solid, rigid gasket.

Understanding this two-part design is the key to deploying these gaskets effectively in demanding industrial environments.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Envelope | PTFE | Chemical resistance, contamination prevention |

| Inner Core | Compressed fiber or elastomer | Mechanical strength, compressibility, seal integrity |

Need a reliable seal for aggressive chemicals?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets. Our precision production ensures your gaskets provide unmatched chemical resistance and reliable sealing for your specific application in the semiconductor, medical, laboratory, or industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, delivering the exact solution you need.

Contact us today for a quote and let our experts help you solve your toughest sealing challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- In which industries are Teflon O-rings commonly used? Sealing Solutions for Extreme Conditions

- Why is mineral-filled PTFE used in medical and food industries? | Superior Durability Meets FDA-Compliant Safety

- What role does chemical stability play in the performance of Teflon gland fillers? Ensure Long-Term Reliability in Harsh Environments

- What are the advantages of ePTFE's microporous structure? Achieve Selective Permeability for Your Product

- What are the key properties of PTFE oil seals? Superior Performance for Extreme Environments

- What are the key features of spiral PTFE backup rings? Superior Extrusion Protection for High-Pressure Seals

- What additional qualities make PTFE energized seals suitable for aerospace use? Ensuring Reliability in Extreme Environments

- What is the alternative to PTFE gaskets that combines its advantages with better sealing properties? Discover Enhanced Sealing Solutions