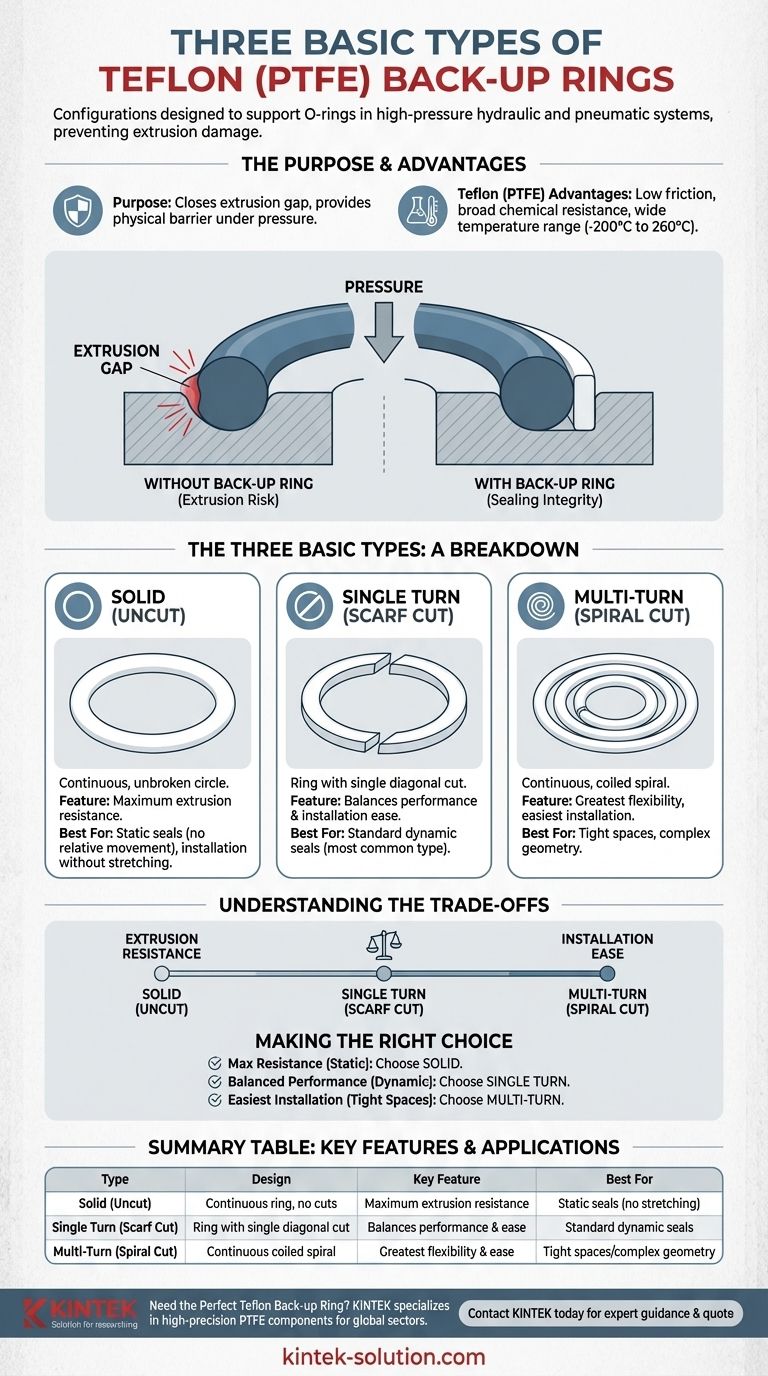

The three fundamental types of Teflon back-up rings are solid (uncut), single turn (scarf cut), and multi-turn (spiral cut). These configurations are designed to support O-rings in high-pressure hydraulic and pneumatic systems, preventing the O-ring from being damaged or forced into the clearance gap between sealing surfaces, a failure known as extrusion. The choice between them depends entirely on the specific demands of the application.

The decision between a solid, single-turn, or spiral-cut ring is a direct trade-off between maximizing extrusion resistance and simplifying installation. Your application—whether it is static or dynamic—will be the primary factor in determining the correct design.

The Purpose of a Teflon Back-up Ring

Why Back-up Rings are Necessary

In any sealing system, there is a small gap between the moving and stationary parts, known as the extrusion gap. When system pressure increases, the O-ring is forced against this gap. If the pressure is high enough, the O-ring material can be pushed into the gap, causing it to be nibbled, sheared, and ultimately fail.

A back-up ring is a rigid, precisely machined ring that sits in the groove alongside the O-ring. It is made of a harder material than the O-ring and serves as a physical barrier, closing off the extrusion gap and providing crucial support under pressure.

The Advantages of Teflon (PTFE)

Teflon, or Polytetrafluoroethylene (PTFE), is the most common material for back-up rings for several key reasons.

Its extremely low coefficient of friction minimizes wear in dynamic applications, while its broad chemical resistance ensures it won't degrade when exposed to aggressive hydraulic fluids or chemicals. Furthermore, its wide operating temperature range (-200°C to 260°C) makes it suitable for demanding environments.

A Breakdown of the Three Basic Types

The three core designs each offer a different balance of sealing integrity and installation flexibility.

Solid (Uncut) Rings

Solid rings are continuous, unbroken circles of PTFE. Because they have no cuts or splits, they provide the absolute maximum resistance to extrusion. The entire surface of the ring is uniform, leaving no potential path for the O-ring to be forced through.

This design is the superior choice for static applications where the two sealed components do not move relative to each other and installation does not require the ring to be stretched.

Single Turn (Scarf Cut) Rings

This is the most common type of back-up ring. It is essentially a solid ring with a single diagonal cut (a "scarf cut") through its cross-section.

This cut allows the ring to be slightly opened and expanded, making installation much easier, especially in dynamic applications where the ring must be fitted over a piston rod or into a cylinder bore. The angled cut helps ensure the ends overlap smoothly once installed, minimizing the extrusion path.

Multi-Turn (Spiral Cut) Rings

A spiral cut ring is machined from PTFE as a continuous, coiled spiral, similar to a spring. This design provides the greatest flexibility and ease of installation.

It can be easily wound into a gland or stretched over a shaft without the risk of permanent deformation. This makes it ideal for installations in tight spaces or where the ring must be maneuvered around complex component geometry.

Understanding the Trade-offs

Choosing the right back-up ring requires acknowledging the compromises inherent in each design.

Extrusion Resistance vs. Installation Ease

The fundamental trade-off is simple: a solid ring offers the best possible seal but is the most difficult to install. Any cut introduced to the ring simplifies installation but creates a potential, albeit small, path for extrusion.

A scarf cut is a balanced compromise, while a spiral cut prioritizes installation flexibility above all else.

Static vs. Dynamic Applications

This is the most critical deciding factor. For a static face seal where the ring can be dropped into place, a solid ring is always the preferred choice for its superior performance.

For dynamic seals, such as on a moving piston or rod, installation requires stretching the ring. A solid ring cannot be used here, making scarf-cut or spiral-cut rings the necessary and correct solution.

Specialized Configurations

The three basic types are often modified for specific needs. You may encounter versions labeled "heavy duty" with a thicker cross-section for higher pressures or "contoured" rings with a curved face that perfectly matches the shape of the O-ring. These are simply adaptations of the three fundamental solid, scarf-cut, and spiral designs.

Making the Right Choice for Your Application

Use your system's requirements to guide your selection.

- If your primary focus is maximum extrusion resistance in a static seal: Choose a solid (uncut) back-up ring for its gap-free construction.

- If your primary focus is a standard dynamic seal requiring a balance of performance and simple installation: A single turn (scarf cut) ring is the most common and effective choice.

- If your primary focus is installation in a restricted space or over components with large diameters: A multi-turn (spiral cut) ring offers the most flexibility to prevent installation damage.

By understanding these core designs, you can select the precise back-up ring that ensures the integrity and longevity of your sealing system.

Summary Table:

| Type | Design | Key Feature | Best For |

|---|---|---|---|

| Solid (Uncut) | Continuous ring with no cuts | Maximum extrusion resistance | Static seals where installation doesn't require stretching |

| Single Turn (Scarf Cut) | Ring with a single diagonal cut | Balances performance and installation ease | Standard dynamic seals (most common type) |

| Multi-Turn (Spiral Cut) | Continuous, coiled spiral | Greatest flexibility and easiest installation | Tight spaces or complex component geometry |

Need the Perfect Teflon Back-up Ring for Your Application?

KINTEK specializes in manufacturing high-precision PTFE components, including custom back-up rings for the semiconductor, medical, laboratory, and industrial sectors. We ensure your sealing systems perform reliably under pressure, from prototype to high-volume production.

Contact KINTEK today for expert guidance and a quote tailored to your specific needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications