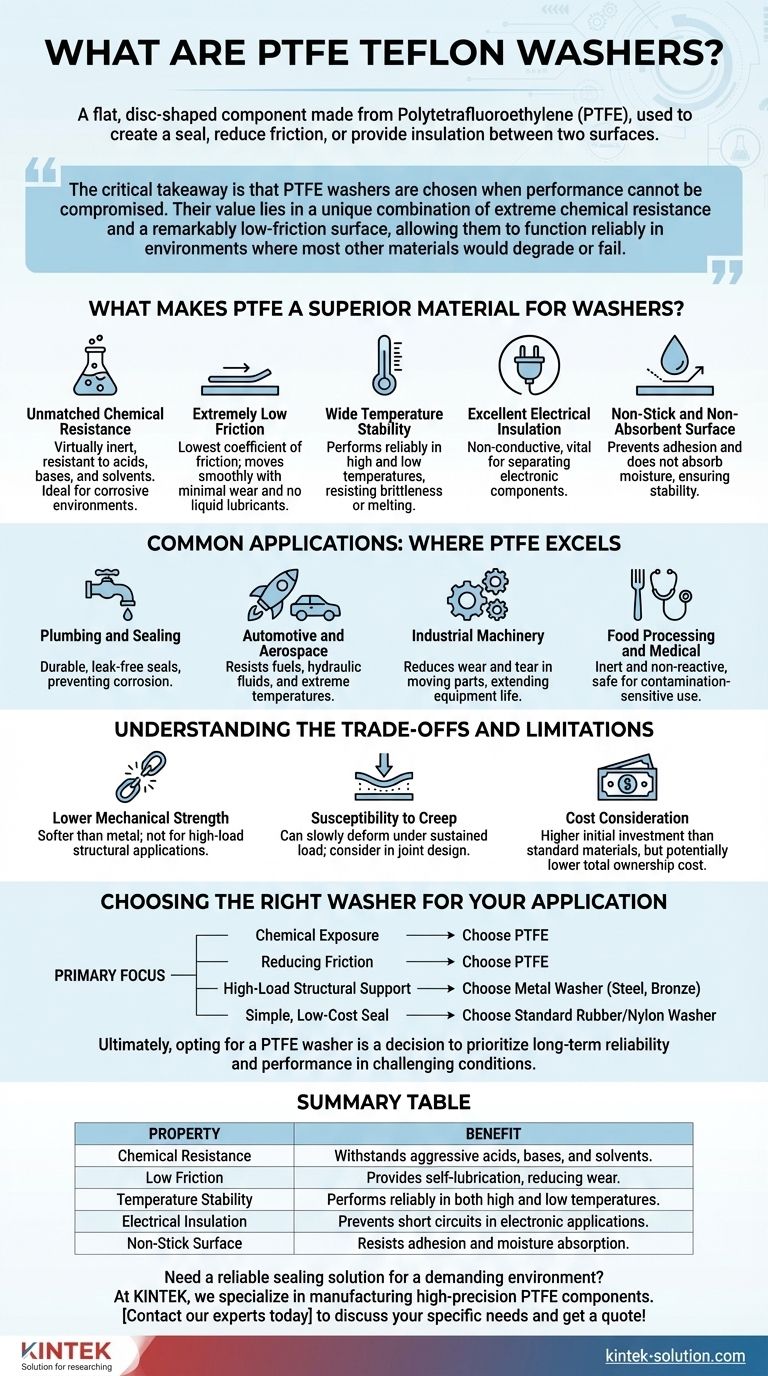

At its core, a PTFE Teflon washer is a flat, disc-shaped component made from the polymer Polytetrafluoroethylene (PTFE). It is used to create a seal, reduce friction, or provide insulation between two surfaces. These washers are valued for their unique combination of properties, making them indispensable in applications from common plumbing fixtures to high-performance aerospace machinery.

The critical takeaway is that PTFE washers are chosen when performance cannot be compromised. Their value lies in a unique combination of extreme chemical resistance and a remarkably low-friction surface, allowing them to function reliably in environments where most other materials would degrade or fail.

What Makes PTFE a Superior Material for Washers?

The effectiveness of a PTFE washer is not due to a single characteristic, but rather a powerful combination of several inherent properties of the material itself. This makes it a go-to solution for demanding engineering challenges.

Unmatched Chemical Resistance

PTFE is virtually inert, meaning it shows tremendous resistance to a wide spectrum of chemicals, including aggressive acids, bases, and solvents. This prevents it from reacting with or degrading in corrosive environments. This property is crucial in chemical processing plants and laboratories.

Extremely Low Friction

Often compared to wet ice on wet ice, PTFE has one of the lowest coefficients of friction of any solid material. This allows parts to move smoothly against each other with minimal wear and without the need for liquid lubricants.

Wide Temperature Stability

These washers perform reliably across a broad range of temperatures. They are ideal for many low-temperature applications and can withstand significant heat, maintaining their integrity where many plastics or rubbers would become brittle or melt.

Excellent Electrical Insulation

PTFE is a non-conductive material, making it an excellent electrical insulator. This property is vital for separating electronic components and preventing short circuits in electrical and aerospace applications.

Non-Stick and Non-Absorbent Surface

The non-stick surface of Teflon prevents other materials from adhering to it. Furthermore, PTFE does not absorb moisture, ensuring its dimensions and properties remain stable even in humid conditions.

Common Applications: Where PTFE Excels

The unique properties of PTFE washers make them a critical component across numerous industries where reliability and durability are paramount.

Plumbing and Sealing

Their chemical inertness and water resistance make them perfect for creating durable, leak-free seals in faucets and pipe fittings, preventing corrosion over time.

Automotive and Aerospace

In these industries, washers are exposed to fuels, hydraulic fluids, and extreme temperatures. PTFE's resistance to these conditions and its low-friction properties ensure parts operate smoothly and safely.

Industrial Machinery

For machinery that involves moving parts, PTFE washers reduce wear and tear, extending the life of the equipment and reducing the need for maintenance and lubrication.

Food Processing and Medical

Because PTFE is inert and non-reactive, it is safe for use in equipment for food processing and medical devices where contamination must be avoided.

Understanding the Trade-offs and Limitations

While versatile, PTFE washers are not the universal solution for every application. Understanding their limitations is key to using them effectively.

Lower Mechanical Strength

Compared to metal washers, PTFE is a much softer material. It is not suitable for high-load structural applications where immense compressive strength is the primary requirement.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time, a phenomenon known as "creep." This must be accounted for in the design of joints that will be under high pressure for long periods.

Cost Consideration

High-performance materials often come with a higher price tag. While their longevity can lead to a lower total cost of ownership, the initial investment for PTFE washers is typically greater than for standard rubber or nylon alternatives.

Choosing the Right Washer for Your Application

Selecting the correct material is about matching its properties to the demands of the environment.

- If your primary focus is chemical exposure: Choose PTFE for its unmatched inertness against acids, bases, and solvents.

- If your primary focus is reducing friction in moving parts: PTFE is the ideal choice for creating a smooth, self-lubricating surface.

- If your primary focus is high-load structural support: A metal washer (like steel or bronze) is a more appropriate choice.

- If your primary focus is a simple, low-cost seal for a non-corrosive environment: A standard rubber or nylon washer may be sufficient.

Ultimately, opting for a PTFE washer is a decision to prioritize long-term reliability and performance in challenging conditions.

Summary Table:

| Property | Benefit |

|---|---|

| Chemical Resistance | Withstands aggressive acids, bases, and solvents. |

| Low Friction | Provides self-lubrication, reducing wear. |

| Temperature Stability | Performs reliably in both high and low temperatures. |

| Electrical Insulation | Prevents short circuits in electronic applications. |

| Non-Stick Surface | Resists adhesion and moisture absorption. |

Need a reliable sealing solution for a demanding environment?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Our expertise ensures your parts meet the highest standards for chemical resistance, temperature stability, and low friction, critical for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, delivering the precision and reliability your application demands.

Contact our experts today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What makes PTFE seats suitable for demanding environments in butterfly valves? Unlock Chemical & Thermal Resilience

- What are some specific applications of CNC machined Teflon parts? Essential Components for Demanding Industries

- What considerations are important when selecting Teflon for CNC machining? Master Its Unique Challenges

- How do PTFE control valves contribute to industrial safety? Prevent Leaks & Ensure Process Integrity

- What are PTFE Bellows and what material are they made from? Discover the Key to Chemical Resistance & Flexibility

- What are the typical applications of PTFE bearing pads? Managing Movement in Bridges and Large Structures

- What are the tolerances for PTFE balls? Achieve Precision in Your Application

- What makes PTFE reducing flanges an excellent choice for piping systems? Achieve Superior Corrosion Resistance and Reliability