In essence, PTFE control valves significantly enhance industrial safety by creating a chemically inert and reliable barrier against hazardous materials. Their primary contributions are preventing catastrophic corrosion that can lead to leaks and ensuring a tight, dependable seal that contains aggressive or high-purity media.

The core safety benefit of PTFE in control valves stems from a powerful combination of properties: its near-universal chemical resistance prevents material failure, while its non-stick, durable nature ensures consistent sealing performance, minimizing both immediate leak risks and long-term maintenance hazards.

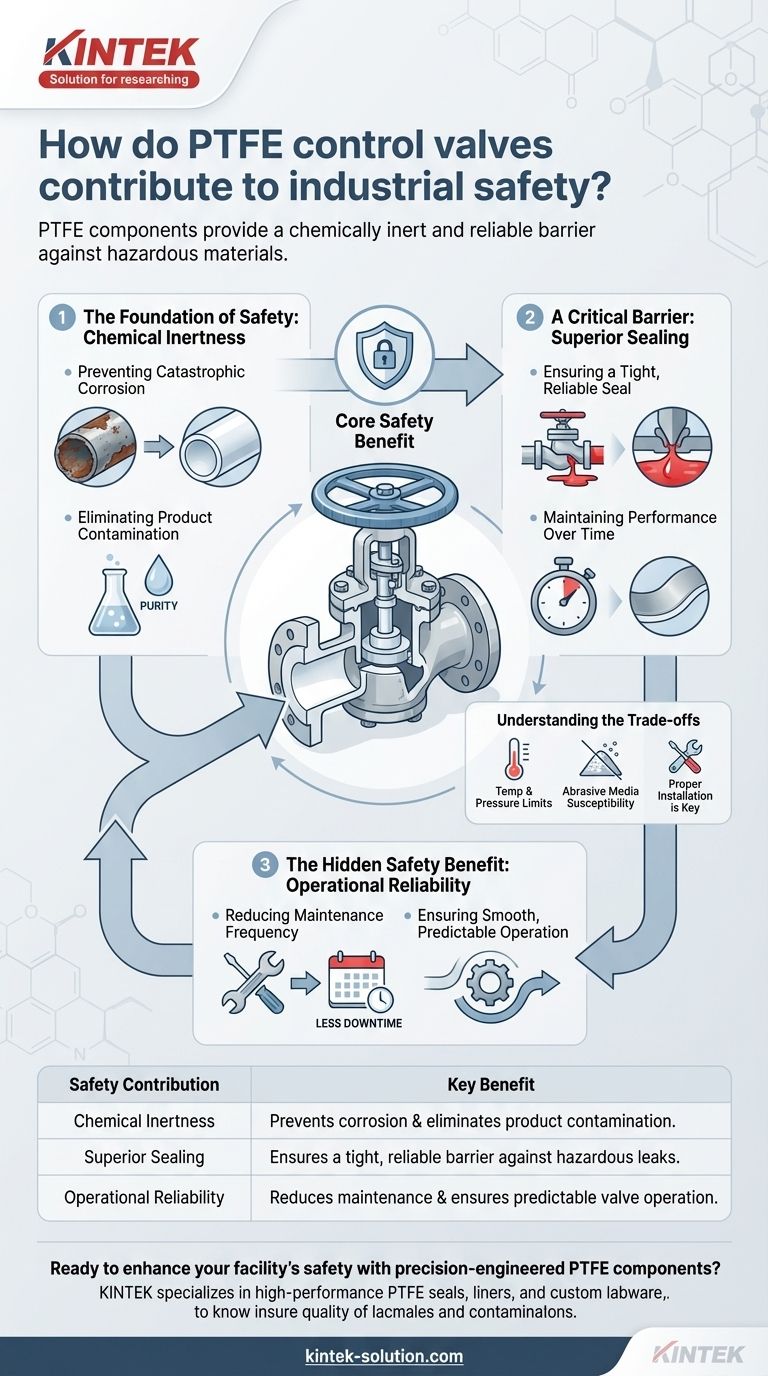

The Foundation of Safety: Chemical Inertness

The first line of defense in any industrial process is material integrity. When a valve's material cannot withstand the process media, the foundation of safety is compromised. PTFE's unique chemical properties provide this foundational stability.

Preventing Catastrophic Corrosion

Most industrial accidents involving fluid handling are rooted in material failure, often caused by corrosion. Aggressive acids, caustics, and solvents can eat away at standard metal components, leading to valve failure and uncontrolled releases.

PTFE is chemically inert to nearly all industrial chemicals. By using it for wetted parts—the surfaces that directly contact the process fluid—you effectively eliminate corrosion as a failure point.

Eliminating Product Contamination

In industries like pharmaceuticals, food processing, and semiconductors, safety isn't just about containment; it's about purity. Product contamination can pose a direct threat to consumers.

The non-stick, non-reactive surface of PTFE ensures that the valve does not leach materials into the process media or allow substances to accumulate on its surface, preserving product integrity.

A Critical Barrier: Superior Sealing

A valve's most basic function is to control flow, which requires the ability to seal perfectly. This is especially critical when the media is toxic, flammable, or otherwise hazardous.

Ensuring a Tight, Reliable Seal

PTFE's properties make it an exceptional material for liners, seats, and seals within a valve. It creates a tight barrier that effectively prevents the escape of dangerous substances into the surrounding environment.

This robust sealing capability is the most direct way PTFE components prevent safety incidents, protecting both personnel and equipment from exposure.

Maintaining Performance Over Time

The non-stick, low-friction nature of PTFE prevents process media from sticking to and building up on the valve's internal surfaces.

This is crucial because material accumulation can cause a valve to seize or fail to close completely, compromising the seal and creating a significant operational hazard.

Understanding the Trade-offs

While highly effective, PTFE components are not a universal solution. Acknowledging their limitations is key to using them safely and effectively.

Temperature and Pressure Limitations

PTFE has specific operating temperature and pressure ceilings. Exceeding these limits can lead to material degradation and mechanical failure. It is critical to select a valve rated for your specific process conditions.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. While durable, it can be susceptible to wear and damage in applications with highly abrasive slurries or solids, which could eventually compromise sealing integrity.

The Importance of Proper Installation

The performance of any sealing component is highly dependent on correct installation. Improperly torqued flanges or misaligned parts can create leak paths, negating the benefits of the material itself.

The Hidden Safety Benefit: Operational Reliability

A truly safe system is not only robust but also reliable. PTFE contributes to safety by enhancing the long-term operational stability of the valve and the system as a whole.

Reducing Maintenance Frequency

The durability and wear-resistance of PTFE mean that valves require less frequent service, repair, or replacement.

Reducing maintenance cycles directly improves safety by minimizing the need for personnel to intervene in potentially hazardous process lines.

Ensuring Smooth, Predictable Operation

PTFE's low-friction surface ensures that the valve actuates smoothly and consistently without sticking. This reliability is vital for precise process control and for ensuring the valve will function as designed during an emergency shutdown.

Making the Right Choice for Your Goal

To leverage PTFE effectively, align your component selection with your primary safety objective.

- If your primary focus is handling highly corrosive chemicals: Prioritize valves with fully PTFE-lined wetted parts to create a complete barrier between the aggressive media and the valve body.

- If your primary focus is preventing product contamination: Select valves where PTFE's non-stick, high-purity surface ensures no material can accumulate or leach into your process fluid.

- If your primary focus is maximizing operational uptime and worker safety: The low-maintenance, high-reliability nature of PTFE components will reduce system downtime and limit personnel exposure to hazardous environments.

Ultimately, integrating PTFE control valves is a strategic decision to build a more resilient, predictable, and fundamentally safer industrial process.

Summary Table:

| Safety Contribution | Key Benefit |

|---|---|

| Chemical Inertness | Prevents corrosion and eliminates product contamination from aggressive media. |

| Superior Sealing | Ensures a tight, reliable barrier against toxic or hazardous substance leaks. |

| Operational Reliability | Reduces maintenance frequency and ensures predictable, safe valve operation. |

Ready to enhance your facility's safety with precision-engineered PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are designed to provide the chemical resistance and reliable sealing you need to protect your personnel, processes, and products.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit for your specific safety requirements.

Contact KINTEK today to discuss your application and discover how our PTFE solutions can build a safer, more reliable process for you.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How are PTFE seals used in medical device and life sciences applications? Essential for Sterility & Precision

- What should be considered when milling Teflon? Master Machining for Precision PTFE Parts

- What are common applications of machined Teflon (PTFE) parts? Solve Demanding Engineering Challenges

- What role do PTFE lined ball valves play in natural gas transmission? Ensuring Safety and Reliability

- What processing methods are typically used for PTFE? Mastering the Unique Path from Powder to Precision Part

- How do you use a Teflon sheet for heat press applications? Protect Your Projects and Equipment

- What are the common applications of PTFE beyond non-stick cookware? Unlock High-Performance Solutions

- What are the advantages of square rings over O-rings in static applications? Achieve Superior High-Pressure Sealing