At its core, the suitability of Polytetrafluoroethylene (PTFE) seats for demanding environments in butterfly valves stems from a unique combination of three properties: exceptional chemical inertness, high thermal stability, and an extremely low coefficient of friction. This trifecta allows PTFE to create a reliable, non-reactive seal that withstands aggressive media and operational stress where other materials would quickly fail.

The fundamental advantage of PTFE is its ability to act as an impermeable and non-stick barrier. It effectively isolates the valve's metal components from corrosive chemicals and extreme temperatures, ensuring both the integrity of the valve and the purity of the media passing through it.

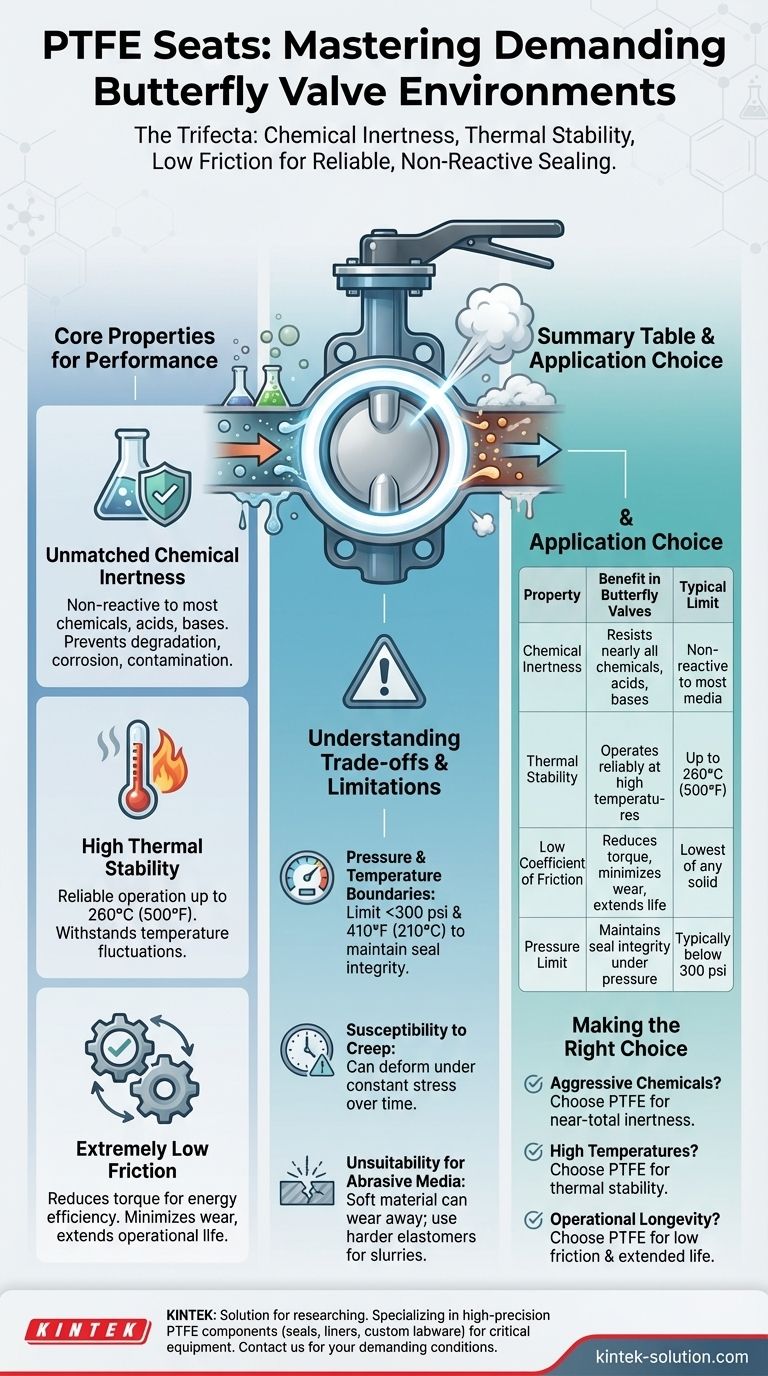

The Core Properties of PTFE in Valve Design

To understand why PTFE is a default choice for harsh applications, we must examine how its intrinsic characteristics translate directly to valve performance and longevity.

Unmatched Chemical Inertness

PTFE is renowned for being non-reactive to nearly all industrial chemicals, acids, and bases. This chemical inertness is its most critical feature for industries like chemical processing and pharmaceuticals.

This property prevents the valve seat from degrading, swelling, or corroding upon contact with aggressive substances. It ensures the valve maintains its sealing capability and prevents contamination of the process media.

High Thermal Stability

PTFE seats can operate reliably across a wide temperature range, with a general upper limit of around 260°C (500°F). This allows them to be used in processes involving hot fluids or steam that would cause other elastomers to break down.

The material's stability ensures the seal remains consistent and effective, even when subjected to significant temperature fluctuations.

Extremely Low Coefficient of Friction

Often described as having a "non-stick" surface, PTFE has one of the lowest friction coefficients of any solid material. This property has two major benefits in a butterfly valve.

First, it significantly reduces the torque required to open and close the valve, which allows for smaller, more energy-efficient actuators. Second, it minimizes wear and tear on the seat and the valve disc, drastically increasing the operational life of the valve and reducing maintenance needs.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its operational boundaries and potential weaknesses.

Pressure and Temperature Boundaries

Despite its high-temperature tolerance, PTFE's performance is interdependent with pressure. In high-performance butterfly valves, it is typically specified for conditions below 300 psi and 410°F (210°C). Exceeding these combined limits can compromise the integrity of the seal.

Susceptibility to Creep

PTFE is a softer material that can be subject to "creep" or cold flow. Under high, constant mechanical stress (like a tightly closed valve under pressure), the material can slowly deform over time. This can eventually affect the long-term quality of the seal in high-pressure applications.

Unsuitability for Abrasive Media

The non-stick surface of PTFE is not optimized for handling abrasive slurries. Hard, sharp particles in the media can physically wear away the soft PTFE material, leading to premature seat failure and leakage. In such cases, a harder elastomer like EPDM might be a more durable choice.

Making the Right Choice for Your Application

Selecting the correct valve seat material requires matching the material's properties to the specific demands of your system.

- If your primary focus is handling aggressive chemicals: PTFE is the industry standard due to its near-total chemical inertness, which prevents valve corrosion and media contamination.

- If your primary focus is high-temperature media (within limits): PTFE's thermal stability provides a reliable seal in processes where common elastomers would degrade and fail.

- If your primary focus is operational longevity and low maintenance: PTFE's low-friction surface minimizes wear and reduces actuation torque, extending the valve's service life.

Ultimately, choosing PTFE is a decision to prioritize chemical and thermal resilience for complex and demanding fluid control systems.

Summary Table:

| Property | Benefit in Butterfly Valves | Typical Limit |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals, acids, and bases | Non-reactive to most media |

| Thermal Stability | Operates reliably at high temperatures | Up to 260°C (500°F) |

| Low Coefficient of Friction | Reduces torque, minimizes wear, extends valve life | One of the lowest of any solid |

| Pressure Limit | Maintains seal integrity under pressure | Typically below 300 psi |

Need a PTFE component that stands up to your most demanding conditions?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your butterfly valves and other critical equipment perform reliably, even when faced with aggressive chemicals, extreme temperatures, and rigorous operational stress.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and durability to meet your exact specifications.

Contact us today to discuss how our PTFE solutions can enhance your valve performance and system reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech