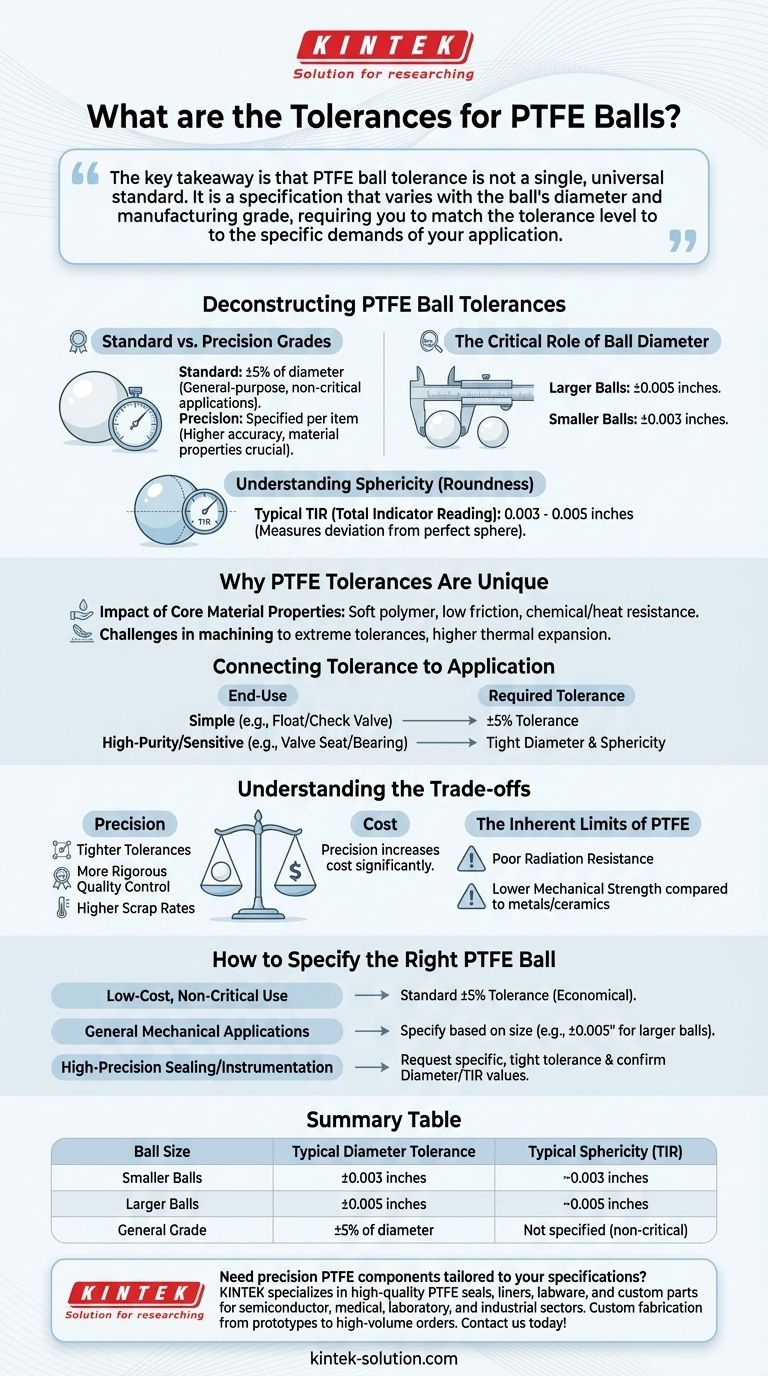

The tolerance for a PTFE ball depends directly on its size and the required precision grade. A general-purpose standard tolerance is often cited as ±5% of the diameter, but for most engineering applications, more specific values apply: larger balls typically hold a tolerance of ±0.005 inches, while smaller balls can achieve a tighter tolerance of ±0.003 inches.

The key takeaway is that PTFE ball tolerance is not a single, universal standard. It is a specification that varies with the ball's diameter and manufacturing grade, requiring you to match the tolerance level to the specific demands of your application.

Deconstructing PTFE Ball Tolerances

Understanding the numbers requires looking at the different ways tolerance is specified and the factors that influence it. The broad range exists because PTFE balls are used in everything from low-cost fillers to precision instrumentation.

Standard vs. Precision Grades

The most frequently quoted tolerance is ±5% of the diameter. This is best understood as a general-purpose or non-critical specification, often suitable for applications where the ball's exact size is less important than its material properties.

For applications requiring greater accuracy, you must look at precision-grade tolerances, which are specified per item by the manufacturer.

The Critical Role of Ball Diameter

In precision manufacturing, tolerance is heavily dependent on the size of the component. This is a fundamental principle that applies directly to PTFE balls.

Typically, larger diameter balls are manufactured to a tolerance of ±0.005 inches.

Smaller diameter balls, by contrast, can often be ground to a much tighter tolerance, commonly around ±0.003 inches.

Understanding Sphericity (Roundness)

Beyond diameter, sphericity (or roundness) is a critical measure of a ball's quality. This is often measured as TIR (Total Indicator Reading), which quantifies the deviation from a perfect sphere.

A typical TIR for a PTFE ball is between 0.003 and 0.005 inches. As with diameter, smaller balls often achieve better sphericity.

Why PTFE Tolerances Are Unique

The tolerances for PTFE are directly linked to its unique set of material properties. Understanding why you choose PTFE in the first place helps explain the manufacturing realities and its performance characteristics.

Impact of Core Material Properties

PTFE is not a rigid metal; it is a relatively soft polymer with a very low coefficient of friction. Its excellent chemical resistance and high-temperature performance make it invaluable.

However, these same properties mean it can be more challenging to machine to the extreme tolerances possible with materials like steel or ceramics. Its thermal expansion rate is also higher, which can affect its dimensional stability in fluctuating temperatures.

Connecting Tolerance to Application

The required tolerance is dictated entirely by the end-use. A PTFE ball used as a float or in a simple check valve may function perfectly with a ±5% tolerance.

Conversely, a ball used as a valve seat in a high-purity chemical pump or as a bearing in a sensitive instrument demands a tightly controlled diameter and excellent sphericity to ensure proper sealing and smooth operation.

Understanding the Trade-offs

Selecting the right component involves balancing performance requirements with practical constraints. PTFE is an excellent material, but it's essential to recognize its limitations.

Precision vs. Cost

The relationship between tolerance and cost is direct and unavoidable. Tighter tolerances on diameter and sphericity require more precise manufacturing processes, more rigorous quality control, and result in higher scrap rates.

Therefore, specifying a tolerance tighter than your application truly requires will significantly and unnecessarily increase the cost of the component.

The Inherent Limits of PTFE

While its chemical and thermal properties are superb, PTFE has limitations. Its radiation resistance is poor, and its mechanical strength is low compared to other engineering materials.

These factors are not directly related to tolerance but are critical trade-offs to consider when choosing PTFE for an application.

How to Specify the Right PTFE Ball

Use your application's primary goal to guide your specification. Over-specifying tolerance is a common and costly mistake.

- If your primary focus is low-cost, non-critical use (e.g., filler material): A standard tolerance of ±5% is likely sufficient and the most economical choice.

- If your primary focus is general mechanical applications (e.g., light-load bearings, check valves): Specify a tolerance based on size, such as ±0.005" for larger balls, and consult the manufacturer's standard datasheet.

- If your primary focus is high-precision sealing or instrumentation: You must request a specific, tighter tolerance and confirm both the diameter and TIR values directly from the supplier's technical specifications.

By matching the tolerance to the true need of your design, you ensure optimal performance without over-engineering the solution.

Summary Table:

| Ball Size | Typical Diameter Tolerance | Typical Sphericity (TIR) |

|---|---|---|

| Smaller Balls | ±0.003 inches | ~0.003 inches |

| Larger Balls | ±0.005 inches | ~0.005 inches |

| General Grade | ±5% of diameter | Not specified (non-critical) |

Need precision PTFE components tailored to your specifications? KINTEK specializes in manufacturing high-quality PTFE seals, liners, labware, and custom parts for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring the exact tolerances your application requires. Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What materials are processed into CNC PTFE parts? A Guide to Stock Shapes and Grades

- What are the benefits of PTFE with Carbon-Graphite Fill? Superior Wear Resistance in Fluid Applications

- What are the key properties of Teflon (PTFE) balls? Essential Guide for Chemical & Thermal Applications

- Why is PTFE particularly suitable for high-speed rotary shaft seals? Achieve Superior Performance and Reliability

- In what forms are Metal-Polymer Bronze Backed PTFE Plain Bearings available? Choose the Right Form for Your Load

- What are the material properties of PTFE relevant to CNC machining? Mastering Softness & Heat for Precision

- What is the temperature range for welded PTFE bellow seals? Unlock Extreme Thermal Performance

- How do PTFE valves perform under high temperatures? Unmatched Thermal Stability for Extreme Environments