In demanding industrial applications, a PTFE reducing flange is an excellent choice because it combines near-universal chemical resistance, a wide operational temperature range, and inherent non-stick properties. These attributes work together to create a highly reliable connection point that enhances system safety, minimizes maintenance, and ensures process efficiency.

The core value of a PTFE reducing flange is not just its material properties, but its ability to solve the fundamental challenges of corrosion, contamination, and flow disruption. This translates directly to a more durable, safer, and cost-effective piping system over its entire operational life.

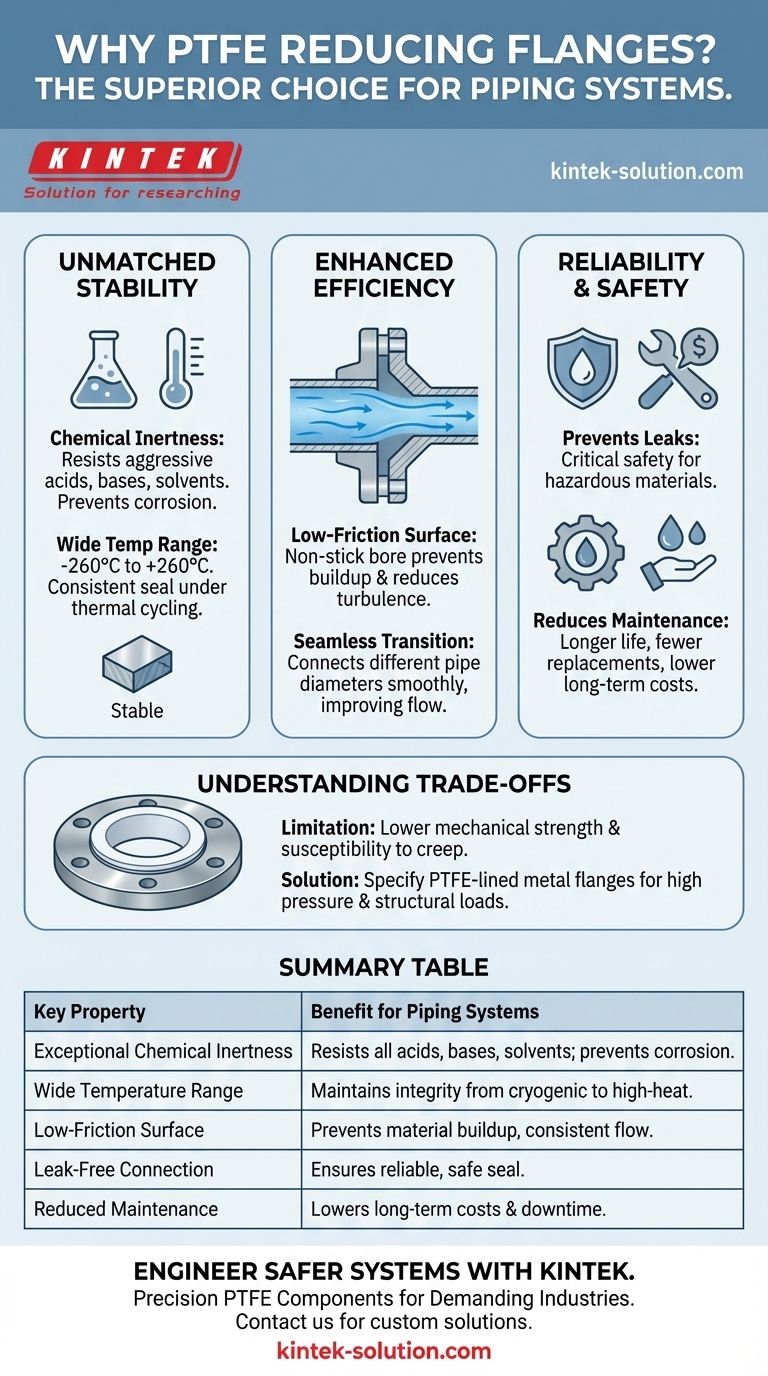

The Foundation: Unmatched Chemical and Thermal Stability

The primary advantages of PTFE (Polytetrafluoroethylene) stem from its unique molecular structure, which gives it extreme resilience in harsh environments.

Exceptional Chemical Inertness

PTFE is one of the most chemically inert materials known. It is virtually immune to attack from aggressive acids, bases, solvents, and other corrosive agents.

This property is critical for preventing corrosion-related failures at the flange connection, which is often a vulnerable point in a piping system. It also ensures the purity of the process fluid by preventing leaching or contamination.

Wide Operational Temperature Range

PTFE maintains its integrity and performance across a vast spectrum of temperatures, from cryogenic levels up to approximately 260°C (500°F).

This outstanding thermal stability means the flange will not become brittle in the cold or degrade in high-heat applications, ensuring a consistent and reliable seal under severe thermal cycling.

Enhancing System Performance and Efficiency

Beyond simple resistance, PTFE actively contributes to the smooth and efficient operation of the piping system.

The Role of a Low-Friction Surface

PTFE has an exceptionally low coefficient of friction, creating a non-stick surface on the wetted parts of the flange.

This smooth bore prevents material buildup, reduces turbulence, and helps maintain consistent flow rates. This is particularly beneficial in processes where product purity and unimpeded flow are essential for productivity.

Seamless Connection and Flow Transition

As a reducing flange, its function is to connect pipes of different diameters. The use of PTFE ensures this transition is smooth and chemically resistant.

By providing a reliable, leak-free joint between different pipe sizes, it improves overall system efficiency and simplifies piping design.

The Practical Impact on Reliability and Safety

The material properties of PTFE translate directly into tangible benefits for system longevity and operator safety.

Preventing Leaks and Failures

The combination of chemical resistance and stable sealing performance drastically reduces the risk of leaks.

In systems handling hazardous materials, this is a non-negotiable safety feature that protects personnel, equipment, and the environment.

Reducing Maintenance and Downtime

Because PTFE resists both chemical attack and material adhesion, components last longer and require less frequent cleaning or replacement.

This inherent durability lowers long-term maintenance costs and minimizes costly unplanned shutdowns, preserving structural integrity and operational uptime.

Understanding the Trade-offs

While highly effective, PTFE is not the solution for every single application. Understanding its limitations is key to proper specification.

Mechanical Strength and Pressure Limits

PTFE is a relatively soft material compared to metals. It has lower tensile strength and is not designed for high-pressure structural loads on its own.

For this reason, PTFE reducing flanges are most often constructed as PTFE-lined metal flanges. This design combines the structural integrity and high-pressure rating of a carbon steel or stainless steel body with the superior chemical resistance of the PTFE liner.

Susceptibility to Creep

Under sustained mechanical load, especially at elevated temperatures, PTFE can be subject to "creep" or cold flow.

This means that over time, the material can slowly deform. It requires careful attention to bolt torque specifications during installation and may require periodic re-torquing to maintain a perfect seal.

Making the Right Choice for Your System

Selecting the correct flange material depends entirely on the specific demands of your process.

- If your primary focus is handling highly corrosive media: PTFE's chemical inertness is the industry gold standard for preventing corrosion and ensuring product purity.

- If your primary focus is operational reliability and reduced maintenance: The durable, non-stick nature of PTFE minimizes failures and cleaning cycles, lowering total cost of ownership.

- If you are dealing with a high-pressure or structurally demanding system: Specify a PTFE-lined metallic flange to gain the benefits of PTFE without compromising on mechanical strength.

By leveraging PTFE's unique properties, you can engineer a piping system that is not only effective but fundamentally safer and more reliable.

Summary Table:

| Key Property | Benefit for Piping Systems |

|---|---|

| Exceptional Chemical Inertness | Resists virtually all acids, bases, and solvents; prevents corrosion and contamination. |

| Wide Temperature Range (-260°C to 260°C) | Maintains integrity and seal from cryogenic to high-heat applications. |

| Low-Friction, Non-Stick Surface | Prevents material buildup, reduces turbulence, and maintains consistent flow. |

| Leak-Free Connection | Ensures a reliable, safe seal between pipes of different diameters. |

| Reduced Maintenance | Lowers long-term costs and minimizes unplanned downtime. |

Engineer a safer, more reliable piping system with precision PTFE components from KINTEK.

If your operations in the semiconductor, medical, laboratory, or industrial sectors demand the superior chemical resistance and non-stick performance of PTFE, our expertise is your solution. KINTEK specializes in the custom fabrication of high-quality PTFE components—including seals, liners, labware, and reducing flanges—from prototypes to high-volume orders.

We prioritize precision production to ensure your equipment meets the highest standards of durability and performance, directly translating to enhanced system safety, reduced maintenance, and lower total cost of ownership.

Contact KINTEK today to discuss your specific requirements and discover how our PTFE solutions can solve your most challenging application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How is PTFE applied in the medical field? Enhancing Patient Care with Biocompatible Solutions

- What are the advantages of PTFE gaskets in terms of chemical resistance? Achieve Unmatched Sealing in Corrosive Environments

- How can PTFE packing be enhanced for specific applications? Tailor Performance with Fillers & Braids

- What are the key characteristics of PTFE coated fasteners? Enhance Durability in Harsh Environments

- What is the preferred composition for PTFE wear resistant material and why? Achieve Superior Performance with Bronze-Filled PTFE

- How do PTFE balls perform against various chemicals? Unmatched Chemical Resistance for Harsh Environments

- What industries benefit the most from using PTFE gaskets? Ensure Reliability in Critical Applications

- What are the main strengths of virgin PTFE? Achieve Unmatched Chemical Purity and Thermal Stability