The defining strengths of virgin PTFE are its extreme chemical inertness, wide thermal stability, excellent electrical insulation, and exceptionally low coefficient of friction. Because it contains no fillers or additives, it also offers a level of purity that is critical for sensitive applications in the medical, pharmaceutical, and food processing industries.

While often chosen for its famous non-stick properties, the core value of virgin Polytetrafluoroethylene (PTFE) lies in its unparalleled chemical and thermal resilience. Understanding its mechanical softness is the key to deploying it effectively.

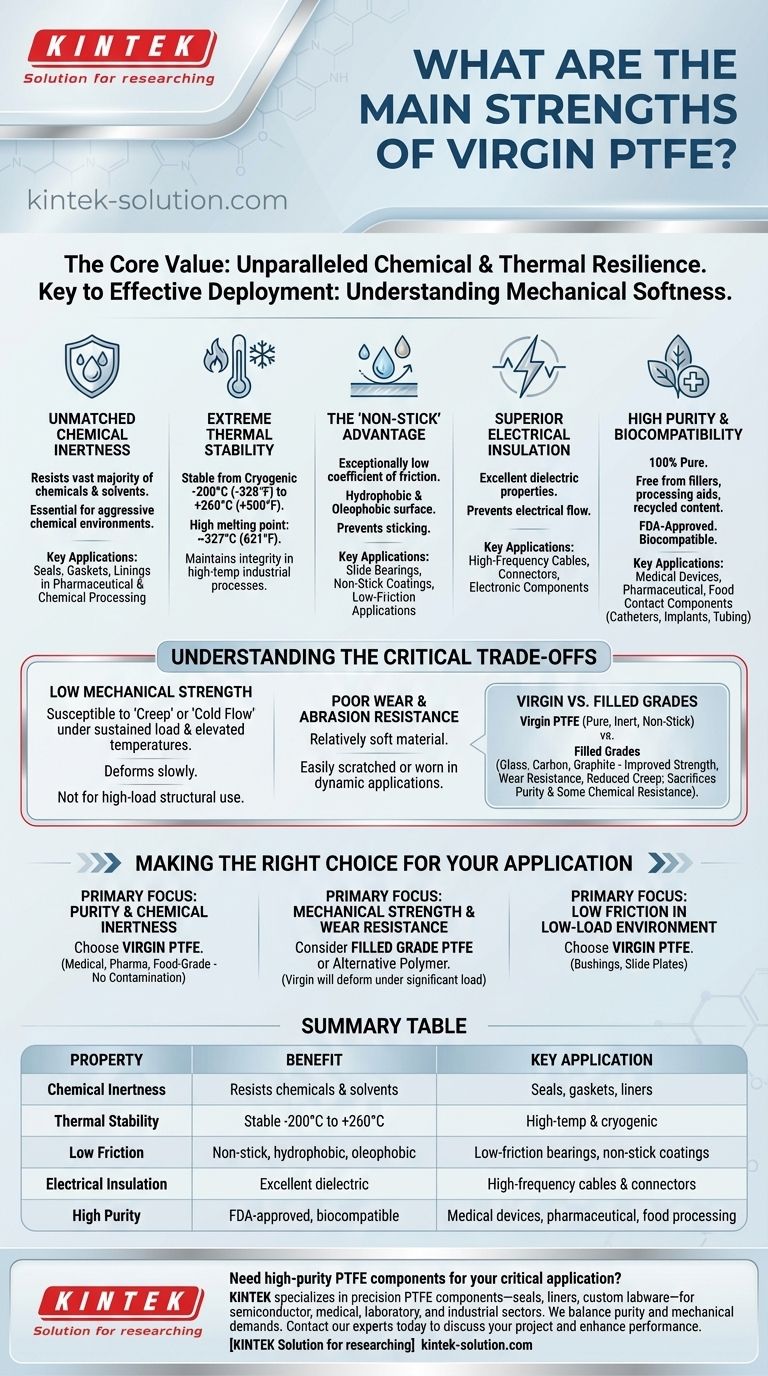

The Defining Properties of Virgin PTFE

Virgin PTFE is a fluoropolymer composed of 100% pure polytetrafluoroethylene. This purity is the source of its most valued characteristics, setting it apart from filled or compounded grades of the material.

Unmatched Chemical Inertness

Virgin PTFE is almost completely inert, meaning it does not react with the vast majority of chemicals and solvents. This makes it an essential material for components used in aggressive chemical environments.

Its high insolubility and resistance to corrosion are why it is heavily relied upon in the pharmaceutical and chemical processing sectors for seals, gaskets, and linings.

Extreme Thermal Stability

The material maintains its properties across an exceptionally wide range of temperatures. It remains stable and functional from cryogenic conditions around -200°C (-328°F) up to +260°C (+500°F).

With a high melting point of approximately 327°C (621°F), it will not degrade or lose integrity in most high-temperature industrial processes.

The "Non-Stick" Advantage

PTFE has one of the lowest coefficients of friction of any known solid material, often compared to wet ice on wet ice. This results in its famous non-stick (anti-adhesion) surface.

Its surface is both hydrophobic (repels water) and oleophobic (repels oil), preventing materials from sticking and making it ideal for low-friction applications like slide bearings or non-stick coatings.

Superior Electrical Insulation

Virgin PTFE possesses excellent electrical insulating properties, highlighted by a very low dielectric constant. This means it can effectively prevent the flow of electricity.

This characteristic makes it a first-choice material for insulating high-frequency cables, connectors, and other critical electronic components where signal integrity is paramount.

High Purity and Biocompatibility

The term "virgin" signifies that the material is free from any recycled content, processing aids, or reinforcing fillers. This absolute purity makes it suitable for direct contact with food and is FDA-approved.

Its biocompatibility also makes it a staple in the medical field for components like catheters, surgical implants, and medical tubing where contamination risk must be eliminated.

Understanding the Critical Trade-offs

No material is perfect. To use virgin PTFE effectively, you must be aware of its inherent limitations, which are often the reason for specifying a filled or alternative grade.

Low Mechanical Strength

The most significant weakness of virgin PTFE is its poor mechanical performance, particularly its susceptibility to creep or "cold flow."

Under a sustained compressive load, especially at elevated temperatures, the material will slowly deform. This makes it unsuitable for high-load structural applications where dimensional stability is critical.

Poor Wear and Abrasion Resistance

The same low-friction quality that makes PTFE non-stick also contributes to its poor resistance to wear and abrasion. It is a relatively soft material that can be easily scratched or worn away in dynamic applications with abrasive contact.

Virgin vs. Filled Grades

To overcome these mechanical weaknesses, fillers like glass fiber, carbon, or graphite are often added to PTFE. These filled grades offer vastly improved strength, wear resistance, and reduced creep, but they do so at the cost of the absolute purity and some of the chemical resistance of the virgin material.

Making the Right Choice for Your Application

Selecting the correct material requires balancing its strengths against the specific demands of your project.

- If your primary focus is purity and chemical inertness: Virgin PTFE is the ideal choice for medical, pharmaceutical, or food-grade applications where contamination is not an option.

- If your primary focus is mechanical strength and wear resistance: You must consider a filled grade of PTFE or a different engineering polymer, as virgin PTFE will likely deform or wear out under significant load.

- If your primary focus is low friction in a low-load environment: The non-stick surface and high flexibility of virgin PTFE are among the best available for components like bushings or slide plates.

Ultimately, choosing virgin PTFE is a decision to prioritize chemical purity and thermal stability over raw mechanical strength.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Resists almost all chemicals and solvents | Seals, gaskets, and liners in chemical processing |

| Thermal Stability | Stable from -200°C to +260°C | High-temperature and cryogenic environments |

| Low Friction | Non-stick, hydrophobic, and oleophobic surface | Low-friction bearings, non-stick coatings |

| Electrical Insulation | Excellent dielectric properties | High-frequency cables and connectors |

| High Purity | FDA-approved, biocompatible, no fillers | Medical devices, pharmaceutical, and food processing |

Need high-purity PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between the unmatched purity of virgin PTFE and the mechanical demands of your application. Whether you require prototypes or high-volume production, our custom fabrication expertise ensures you get the right part for the job.

Contact our experts today to discuss your project requirements and discover how our PTFE solutions can enhance your product's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE used in electrical components? Unmatched Insulation for Extreme Environments

- What are the primary applications of PTFE Teflon washers in plumbing? Ensure Leak-Proof Seals in Harsh Environments

- What are the main advantages of PTFE gaskets over ordinary rubber gaskets? Superior Chemical & Thermal Resistance

- How do spring-loaded lift check valves operate? The Key to Preventing Backflow and Water Hammer

- What are the basic shapes of molded PTFE materials available? A Guide to Stock Forms & Machining

- What toolpath strategies benefit thin-wall PTFE machining? Master Precision with Helical Paths and Low-Stress Techniques

- How does Teflon contribute to contamination control in sensitive environments? A Guide to Purity & Performance

- What industries commonly use PTFE envelope gaskets? Solve Sealing Challenges in Harsh & Pure Environments