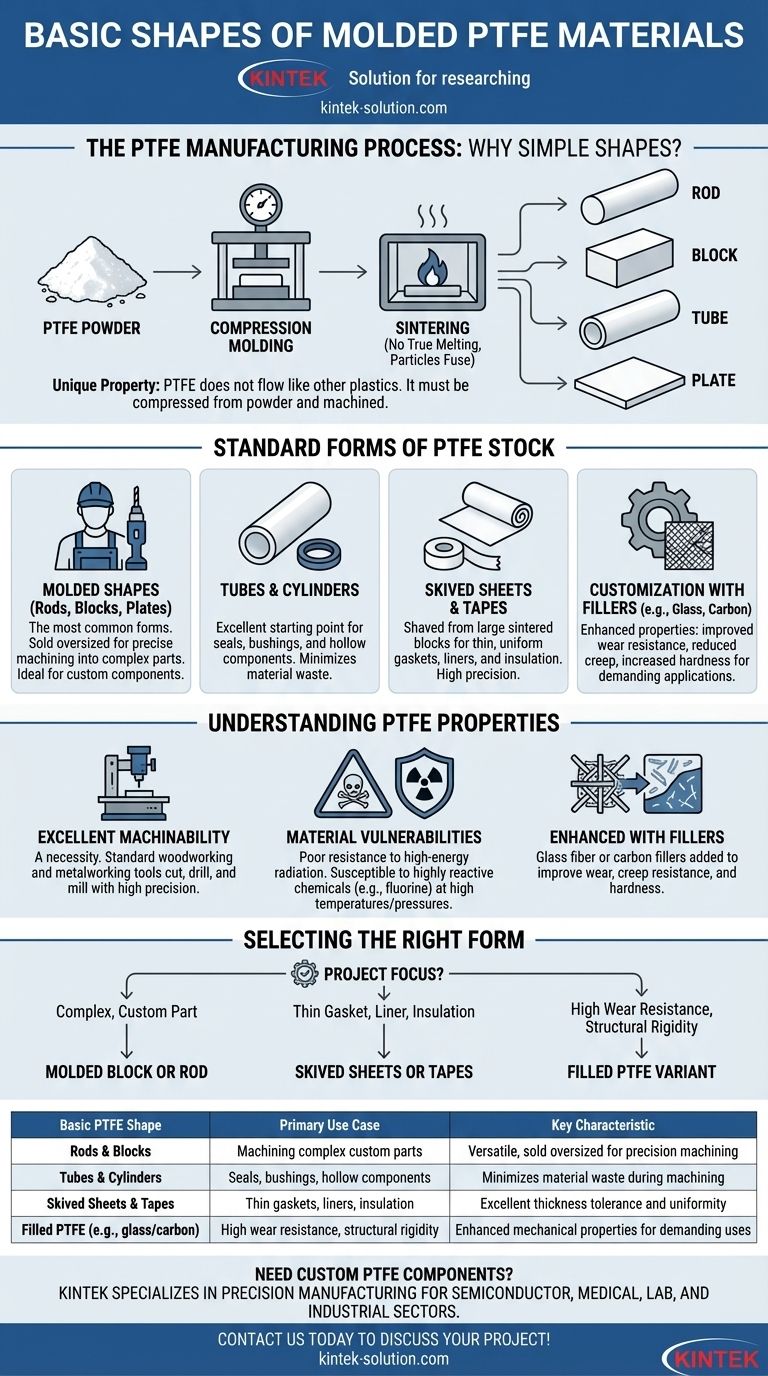

To put it simply, molded Polytetrafluoroethylene (PTFE) is commercially available in basic stock shapes like rods, tubes, plates, and blocks. These fundamental forms exist because PTFE has a unique property: it does not truly melt and flow like other plastics. Instead, it is compressed from a powder into a solid shape, which is then machined into a final, custom component.

The core principle to grasp is that PTFE's inability to be melt-molded into complex geometries is not a limitation but a defining characteristic. This dictates its supply in simple, oversized stock shapes that are prized for their exceptional machinability.

Why PTFE is Limited to Basic Shapes

Understanding the manufacturing process is key to understanding why you can't buy intricate, pre-molded PTFE parts. It behaves fundamentally differently from common thermoplastics.

A Unique Manufacturing Process

PTFE exists as a waxy, powder-like substance. To create a solid form, this powder is compressed under high pressure into a basic shape, a process often called compression molding.

This compressed form is then heated in a sintering oven, where the particles fuse together without ever passing through a true liquid state.

Compression, Not Injection Molding

Unlike materials used in injection molding, PTFE powder cannot be melted and forced into a complex mold cavity. It lacks the necessary flow characteristics.

This is why you must start with a solid block, rod, or plate and remove material to achieve your desired geometry, much like working with wood or metal.

The Standard Forms of PTFE Stock

While the shapes are simple, they come in several variations tailored for different applications.

Molded Shapes (Rods, Blocks, and Plates)

These are the most common forms. They are created by compressing PTFE powder into a mold of the desired basic shape and then sintering it.

These stock materials are intentionally sold slightly oversized. This provides machinists with extra material to ensure they can achieve precise final dimensions after trimming and machining.

Tubes and Cylinders

Tubes are another primary shape, available in both molded and extruded forms. They serve as an excellent starting point for creating seals, bushings, or other hollow components, minimizing the amount of material that needs to be machined away.

Skived Sheets and Tapes

For applications requiring thin, precise sheets, skived PTFE is the solution. This process involves shaving a thin layer from a large, sintered block of PTFE, resulting in a highly uniform and consistent product often used for gaskets or liners.

Understanding the Trade-offs and Limitations

Working with PTFE requires acknowledging its specific properties and how they impact design and application.

Excellent Machinability is a Requirement

The ease with which PTFE can be machined is not just a benefit; it's a necessity. Standard woodworking and metalworking equipment can be used to cut, drill, and mill PTFE with high precision.

Material Vulnerabilities

PTFE is known for its chemical resistance, but it is not invincible. It has poor resistance to high-energy radiation, which can break down its molecular structure.

It is also susceptible to attack from highly reactive chemicals like chlorine trifluoride, elemental fluorine, and other strong fluorinating agents, particularly at high temperatures and pressures.

Customization with Fillers

To enhance specific properties, PTFE is often blended with filler materials. Common fillers like glass fiber or carbon can be added to the powder before molding to improve wear resistance, reduce creep, and increase hardness for more demanding applications.

Selecting the Right PTFE Form for Your Project

Choosing the correct starting shape is the first step in an efficient and cost-effective manufacturing process.

- If your primary focus is machining a complex, custom part: Begin with a molded block or rod, as these provide the most versatile stock for creating intricate geometries.

- If your primary focus is creating a thin gasket, liner, or insulating layer: Specify skived sheets or tapes to ensure you get the best thickness tolerance and surface consistency.

- If your primary focus is high wear resistance or structural rigidity: Request a filled PTFE variant (e.g., glass-filled or carbon-filled) in the appropriate stock shape for your application.

By understanding how PTFE's unique properties dictate its form, you can confidently select the right stock material to machine your perfect component.

Summary Table:

| Basic PTFE Shape | Primary Use Case | Key Characteristic |

|---|---|---|

| Rods & Blocks | Machining complex custom parts | Versatile, sold oversized for precision machining |

| Tubes & Cylinders | Seals, bushings, hollow components | Minimizes material waste during machining |

| Skived Sheets & Tapes | Thin gaskets, liners, insulation | Excellent thickness tolerance and uniformity |

| Filled PTFE (e.g., glass/carbon) | High wear resistance, structural rigidity | Enhanced mechanical properties for demanding uses |

Need a custom PTFE component machined to your exact specifications?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your component meets the highest standards for performance and durability.

Contact us today to discuss your project and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications