In any plumbing system, the primary applications of PTFE (Teflon) washers are to create exceptionally durable, leak-proof seals in demanding environments. They are specifically chosen for their ability to resist degradation from harsh chemicals and to maintain their integrity under high temperatures, making them essential for both industrial and specialized residential plumbing.

The core reason for using a PTFE washer is not just to stop a leak, but to ensure that the seal will last in conditions where other materials like rubber or fiber would quickly fail. Its value comes from its unique combination of chemical inertness, temperature stability, and low-friction properties.

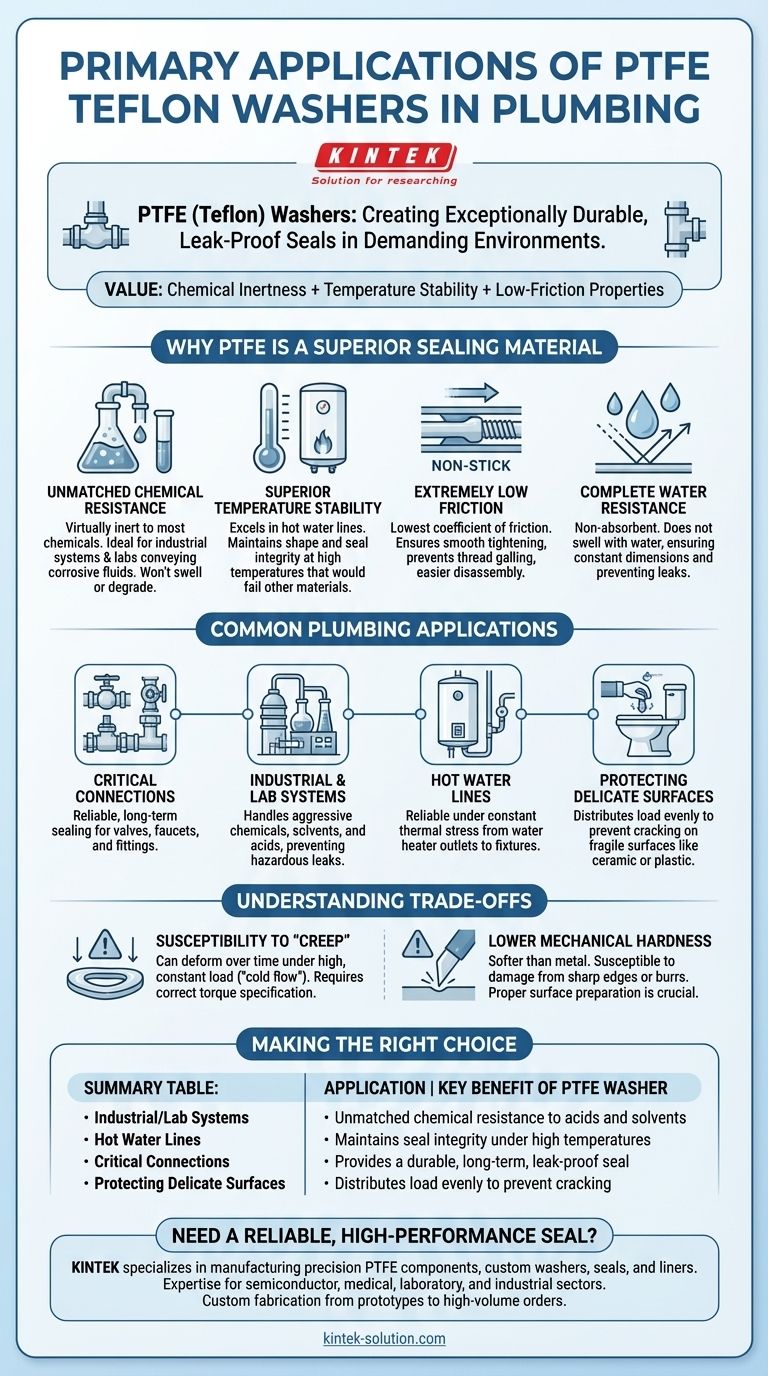

Why PTFE is a Superior Sealing Material

The effectiveness of PTFE washers in plumbing stems from a unique set of material properties. Unlike a standard rubber washer, which is a general-purpose solution, a PTFE washer is a specialized component chosen for its resilience.

Unmatched Chemical Resistance

PTFE is virtually inert, meaning it does not react with most chemicals. This makes it the default choice for industrial plumbing systems that convey corrosive fluids, such as those found in chemical processing plants and laboratories.

This property ensures the washer will not swell, soften, or degrade over time, maintaining a perfect seal where other materials would dissolve or fail.

Superior Temperature Stability

Standard plumbing systems often involve hot water lines. PTFE washers excel in these conditions, maintaining their shape and sealing capability at temperatures that would cause rubber or other plastics to become brittle or deform.

This dimensional stability is critical for preventing leaks in hot water heaters, high-end fixtures, and commercial plumbing applications.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a "non-stick" quality. In plumbing, this allows a connection to be tightened smoothly, creating a secure seal without galling threads or damaging delicate fixture surfaces.

This property also prevents the washer from binding or sticking to the surfaces it's sealing, making disassembly for maintenance much easier.

Complete Water Resistance

PTFE is non-absorbent, meaning it will not absorb water and swell over time. This guarantees that its dimensions and mechanical properties remain constant throughout its service life, preventing potential leaks that can arise from material expansion or degradation.

Common Plumbing Applications

While versatile, PTFE washers are deployed in specific plumbing scenarios where their unique advantages are most needed.

Sealing Critical Connections

They are frequently used in compression fittings, valve assemblies, and faucet connections where a reliable, long-term seal is paramount.

Industrial and Laboratory Systems

Their primary application is in systems handling aggressive chemicals, solvents, or acids. The washer ensures the integrity of the connection and prevents hazardous leaks.

Hot Water Lines

PTFE washers are ideal for any connection on a hot water supply line, from the water heater outlet to the fixture connections, ensuring reliability under constant thermal stress.

Protecting Delicate Surfaces

When fastening a metal fitting to a more fragile material like ceramic or plastic, a PTFE washer is used to distribute the compressive load evenly. Its low-friction surface prevents the fitting from cracking or damaging the surface as it's tightened.

Understanding the Trade-offs

While highly effective, PTFE washers are not a universal solution. Understanding their limitations is key to using them correctly.

Susceptibility to "Creep"

PTFE can slowly deform over time if placed under a constant, high load—a phenomenon known as "creep" or "cold flow." This means it is essential to tighten fittings to the correct torque specification without over-compressing the washer.

Lower Mechanical Hardness

Compared to a metal washer, PTFE is soft. While this is beneficial for sealing, it also means the washer can be easily damaged by sharp edges or burrs on pipes and fittings. Proper surface preparation is crucial.

Cost and Application Specificity

For a simple, non-critical cold water connection, a standard rubber washer is often sufficient and more economical. PTFE washers are a higher-performance component, and their cost is justified in applications where their unique properties are required to prevent failure.

Making the Right Choice for Your Goal

To select the correct washer, you must match the material to the demands of the plumbing environment.

- If your primary focus is handling corrosive chemicals or industrial fluids: PTFE is the essential choice for its unparalleled chemical inertness.

- If your primary focus is sealing hot water lines or high-temperature systems: PTFE provides the necessary stability where standard elastomers would degrade.

- If your primary focus is fastening a fitting to a delicate ceramic or plastic surface: A PTFE washer is the best option to prevent cracking by distributing the load evenly.

- If your primary focus is a general-purpose, cold-water connection: A less expensive rubber or fiber washer is typically adequate, though PTFE offers superior durability.

Ultimately, choosing a PTFE washer is an investment in long-term reliability for the most critical connections in your plumbing system.

Summary Table:

| Application | Key Benefit of PTFE Washer |

|---|---|

| Industrial/Lab Systems | Unmatched chemical resistance to acids and solvents |

| Hot Water Lines | Maintains seal integrity under high temperatures |

| Critical Connections (Valves, Faucets) | Provides a durable, long-term, leak-proof seal |

| Protecting Delicate Surfaces | Distributes load evenly to prevent cracking |

Need a reliable, high-performance seal for your demanding application?

KINTEK specializes in manufacturing precision PTFE components, including custom washers, seals, and liners. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures a leak-proof solution that withstands corrosive chemicals and extreme temperatures.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech