The primary advantages of PTFE gaskets over ordinary rubber lie in their profound chemical inertness, exceptional performance across a vast temperature range, and non-contaminating nature. Unlike rubber, which degrades when exposed to aggressive chemicals or extreme temperatures, PTFE provides a durable, long-lasting seal in the most demanding industrial environments.

While rubber gaskets are a cost-effective choice for general-purpose applications, their limitations are quickly reached. PTFE gaskets represent a significant step-up in material science, engineered specifically for critical applications where chemical, thermal, or purity failures are not an option.

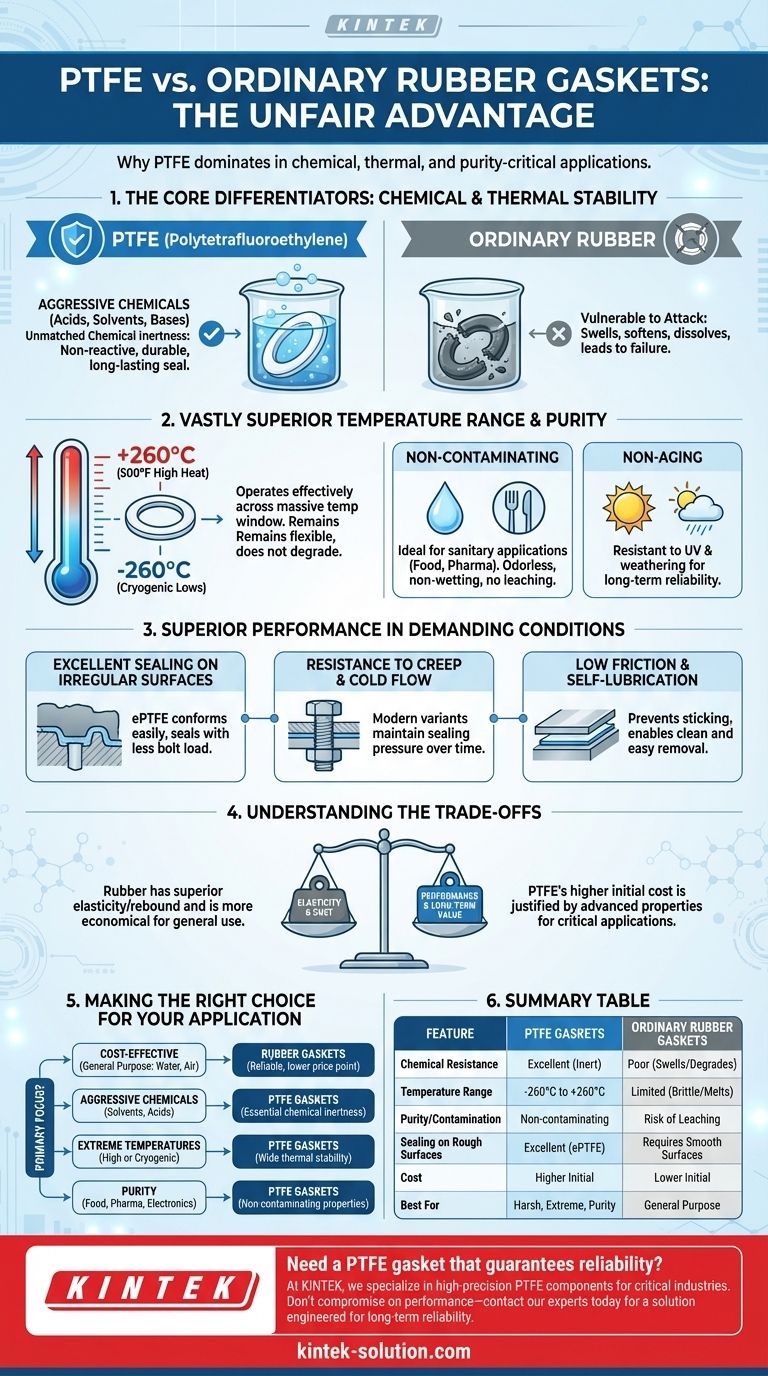

The Core Differentiators: Chemical and Thermal Stability

The fundamental choice between rubber and PTFE often comes down to the operating environment. PTFE was designed to succeed where traditional elastomers like rubber fail.

Unmatched Chemical Inertness

PTFE is renowned for being non-reactive to nearly all chemicals, including aggressive acids, solvents, and bases. This makes it an essential material in chemical processing, pharmaceuticals, and manufacturing.

In contrast, an ordinary rubber gasket can swell, soften, or dissolve when exposed to incompatible chemicals or oils, leading to seal failure and potential leaks.

A Vastly Superior Temperature Range

PTFE gaskets operate effectively in a massive temperature window, from cryogenic lows up to 260°C (500°F). They remain flexible at low temperatures where rubber becomes brittle and do not degrade at high temperatures where rubber would melt or harden.

This stability ensures a reliable seal in applications involving steam, thermal fluids, or extreme environmental conditions.

Non-Contaminating and Non-Aging Properties

Being non-wetting, non-contaminating, and odorless, virgin PTFE is an ideal choice for sanitary applications in the food, beverage, and pharmaceutical industries. It will not impart taste, color, or contaminants into the product.

Furthermore, PTFE is resistant to UV radiation and weathering, giving it excellent non-aging characteristics for long-term reliability, especially in outdoor or exposed equipment.

Superior Performance in Demanding Conditions

Beyond its core stability, PTFE offers unique physical properties that enhance its performance as a sealing material.

Excellent Sealing on Irregular Surfaces

A key variant, expanded PTFE (ePTFE), is exceptionally soft and flexible. It conforms easily to rough or damaged flange surfaces, creating a tight seal with less bolt load than is required for many other gasket materials.

This adaptability can prevent leaks in older equipment and extends the service life of flanges by requiring less clamping force.

Resistance to Creep and Cold Flow

While standard PTFE can be prone to "creep" (deforming slowly under load), modern variants like filled or expanded PTFE offer superior creep resistance. This ensures the gasket maintains its sealing pressure over long periods, reducing the need for re-tightening bolts.

Low Friction and Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property is beneficial in dynamic applications and prevents the gasket from sticking to flange surfaces, making removal clean and easy.

Understanding the Trade-offs

No material is perfect for every situation. Understanding the limitations of PTFE is critical for making an informed decision.

Elasticity and Rebound

Rubber gaskets generally possess superior elasticity and compression memory. They can often seal effectively even after being unbolted and re-torqued.

PTFE, being less elastic, can be more of a "one-time use" gasket. Once compressed, it does not rebound to its original shape as effectively as rubber.

The Cost Factor

For simple, non-demanding applications like sealing water or air at ambient temperatures, rubber gaskets are significantly more economical.

The higher cost of PTFE is justified only when its advanced chemical, thermal, or purity properties are genuinely required to ensure safety and operational integrity.

Making the Right Choice for Your Application

Selecting the correct gasket material is a balance of performance requirements and cost. Your decision should be guided by the specific demands of the service environment.

- If your primary focus is cost-effectiveness for general-purpose sealing (water, air): Rubber gaskets provide reliable performance at a much lower price point.

- If your primary focus is sealing aggressive chemicals, solvents, or acids: PTFE is the essential choice for its near-total chemical inertness.

- If your primary focus is operating in extreme temperatures (high or cryogenic): PTFE's wide thermal stability is required where rubber would quickly fail.

- If your primary focus is purity for food, pharma, or electronics: PTFE's non-contaminating and non-wetting properties are critical to prevent product contamination.

Choosing the right material ensures you are engineering a solution for long-term safety and reliability, not just a temporary fix.

Summary Table:

| Feature | PTFE Gaskets | Ordinary Rubber Gaskets |

|---|---|---|

| Chemical Resistance | Excellent (inert to most chemicals) | Poor (swells, degrades) |

| Temperature Range | -260°C to +260°C | Limited (becomes brittle or melts) |

| Purity/Contamination | Non-contaminating, ideal for sensitive industries | Can leach additives, risk contamination |

| Sealing on Rough Surfaces | Excellent (ePTFE conforms easily) | Requires smooth, even surfaces |

| Cost | Higher initial cost | Lower initial cost |

| Best For | Harsh chemicals, extreme temps, high purity | General purpose, low cost, non-demanding environments |

Need a PTFE gasket that guarantees reliability in your most demanding applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates safely and efficiently, even when exposed to aggressive chemicals, extreme temperatures, or stringent purity requirements.

We offer custom fabrication from prototypes to high-volume orders, tailored to your exact specifications. Don't compromise on performance—contact our experts today to discuss your specific needs and receive a solution engineered for long-term reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs