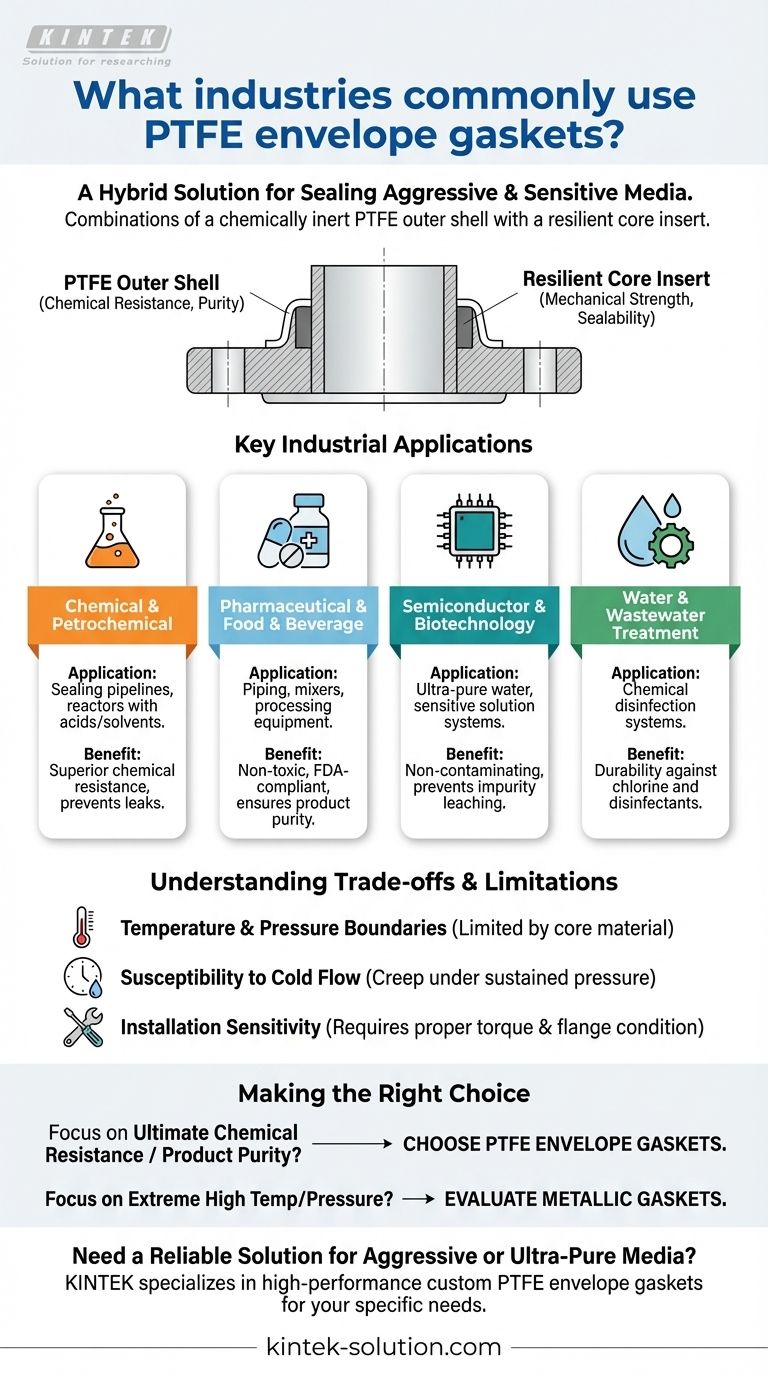

PTFE envelope gaskets are most commonly used in the chemical processing, pharmaceutical, food and beverage, and petrochemical industries. Their unique construction allows them to provide a chemically inert sealing surface for applications involving aggressive media or requiring high purity, where a standard gasket would quickly degrade or contaminate the system.

The core value of a PTFE envelope gasket lies in its composite design: it combines the superior chemical resistance and purity of a PTFE outer shell with the mechanical resilience and compressibility of a core insert material. This makes it the ideal solution for sealing aggressive fluids in systems that cannot tolerate contamination.

The Core Problem: Sealing Aggressive and Sensitive Media

Many industrial processes involve fluids that are either highly corrosive or must remain exceptionally pure. Finding a gasket material that can create a reliable seal without reacting with or contaminating the process media is a significant engineering challenge.

A Hybrid Solution

A PTFE envelope gasket solves this by using two distinct materials. An outer "envelope" or shell is made from PTFE (Polytetrafluoroethylene), which handles all contact with the process fluid.

This envelope encases a softer, more compressible insert material, such as non-asbestos fiber or a specialized rubber like EPDM or FKM.

The PTFE Advantage: Unmatched Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually immune to attack from strong acids, bases, solvents, and other corrosive substances. This property is essential for preventing gasket degradation and leaks in harsh chemical environments.

Furthermore, PTFE is non-toxic and can be manufactured to meet FDA standards, making it safe for direct contact with food and pharmaceutical products.

The Insert's Role: Resilience and Sealability

While PTFE is chemically robust, it can be rigid and susceptible to "cold flow" or creep under pressure. The inner core material provides the mechanical strength and resilience needed to conform to flange imperfections and maintain a tight seal over time.

This inner core compresses under bolt load, creating the necessary "push-back" against the flanges that the PTFE shell alone cannot provide effectively.

Key Industrial Applications Explained

The unique properties of PTFE envelope gaskets make them indispensable in several specific sectors.

For Chemical and Petrochemical Processing

These industries handle a vast range of aggressive chemicals. PTFE envelope gaskets are used to seal flanges on pipelines, reactors, and vessels containing everything from strong acids to volatile solvents, preventing leaks and ensuring operational safety.

For Pharmaceuticals and Food & Beverage

Purity is the primary concern here. The non-toxic and non-contaminating surface of the PTFE envelope ensures that the final product remains unadulterated. These gaskets are frequently used in piping systems, mixers, and processing equipment where cleanliness is paramount.

For Semiconductor and Biotechnology

Similar to pharmaceuticals, these fields demand extreme purity. The non-reactive nature of PTFE prevents it from leaching impurities into the ultra-pure water or sensitive biological solutions used in these manufacturing processes.

For Water & Wastewater Treatment

Treatment facilities use a variety of chemicals to purify water. PTFE envelope gaskets provide durable, long-lasting seals in the presence of chemicals like chlorine and other disinfectants that would quickly destroy standard rubber gaskets.

Understanding the Trade-offs and Limitations

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is key to using them correctly.

Temperature and Pressure Boundaries

The operating temperature of the gasket is often limited by the inner core material, not the PTFE itself. While PTFE can handle high temperatures, the insert material may degrade, compromising the seal. They are generally not suited for the extreme pressure and temperature combinations where metallic gaskets excel.

Susceptibility to Cold Flow

Under sustained high pressure and temperature, PTFE can slowly deform or "creep." This can lead to a loss of bolt torque over time, potentially requiring periodic re-tightening to maintain a reliable seal.

Installation Sensitivity

Proper installation is critical. Uneven or excessive bolt torque can damage the thin PTFE envelope, creating a leak path. The condition of the flange surfaces must be excellent to ensure the gasket can seal effectively.

Making the Right Choice for Your Goal

Selecting the correct gasket requires matching its properties to your primary operational need.

- If your primary focus is ultimate chemical resistance: PTFE envelope gaskets are an excellent choice for sealing aggressive media in applications with moderate temperatures and pressures.

- If your primary focus is product purity and non-contamination: The inert, FDA-compliant nature of these gaskets makes them the standard for pharmaceutical, food, and semiconductor processes.

- If your primary focus is extreme high temperature or pressure: You should evaluate more robust options like spiral wound or ring type joint (RTJ) metallic gaskets, which are designed for those severe conditions.

Ultimately, understanding the unique hybrid nature of the PTFE envelope gasket empowers you to solve sealing challenges that no single material could handle on its own.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Chemical & Petrochemical | Sealing pipelines, reactors with acids/solvents | Superior chemical resistance, prevents leaks |

| Pharmaceutical & Food & Beverage | Piping, mixers, processing equipment | Non-toxic, FDA-compliant, ensures product purity |

| Semiconductor & Biotechnology | Ultra-pure water, sensitive solution systems | Non-contaminating, prevents impurity leaching |

| Water & Wastewater Treatment | Chemical disinfection systems | Durability against chlorine and disinfectants |

Need a reliable sealing solution for aggressive or ultra-pure media?

KINTEK specializes in manufacturing high-performance PTFE components, including custom PTFE envelope gaskets for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a gasket that meets your exact chemical resistance, purity, and durability requirements.

Contact us today to discuss your application and get a tailored solution that protects your process and products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are PTFE oil seals and what makes them unique? Superior Sealing for Extreme Conditions

- How does PTFE's soft nature affect surface finish quality during machining? Mastering the Slice, Not Tear, Process

- What are the advantages of using a PTFE lined ball valve? Achieve Superior Corrosion Resistance & Leak-Proof Sealing

- What factors should be considered when choosing a filler for PTFE? Enhance Performance for Your Application

- What are the key characteristics of PTFE coated fasteners? Enhance Durability in Harsh Environments

- What makes PTFE gaskets suitable for aerospace applications? Unmatched Reliability in Extreme Conditions

- How is expanded PTFE (ePTFE) produced? A Guide to the Controlled Stretching Process

- What are the limitations of PTFE in terms of fabrication? Navigating Manufacturing Challenges