To be direct, the primary fabrication limitations of Polytetrafluoroethylene (PTFE) stem from its exceptional chemical inertness and high melting point. Unlike common thermoplastics, PTFE cannot be processed using conventional melt techniques like injection molding, and its low-friction surface makes it extremely difficult to glue or weld into more complex assemblies.

The very properties that make PTFE uniquely valuable—its extreme chemical resistance and high-temperature stability—are the same properties that prevent it from being fabricated with the ease and speed of other polymers. Success with PTFE requires embracing alternative, often slower, manufacturing processes.

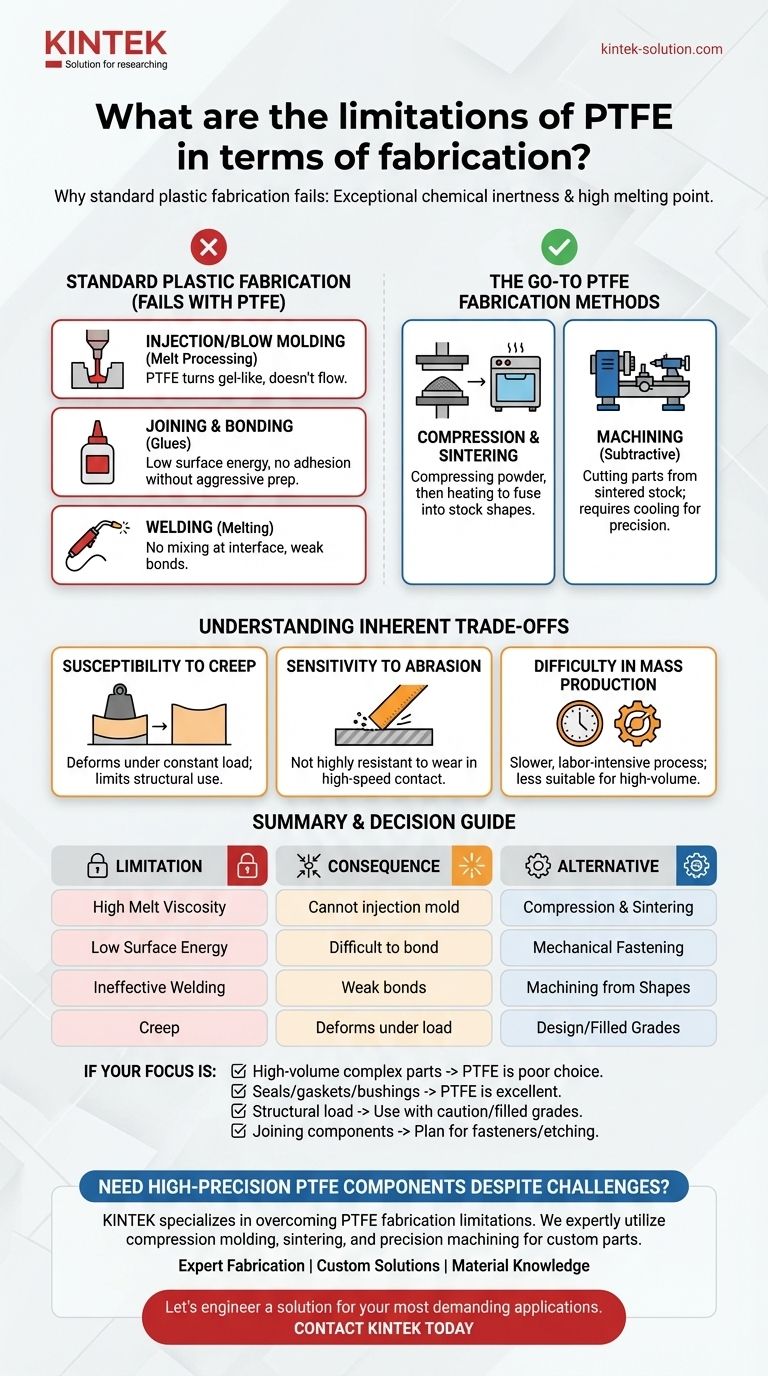

Why Standard Plastic Fabrication Fails with PTFE

Most high-volume plastic parts are made by melting polymer pellets and forcing the liquid into a mold. This entire approach is fundamentally incompatible with the molecular nature of PTFE.

The Problem with Melt Processing

Even when heated above its melting point of approximately 327°C, PTFE does not flow like a typical liquid. It maintains an extremely high melt viscosity, turning into a gel-like substance rather than a fluid that can be easily injected into a mold.

This behavior effectively rules out common fabrication methods like injection molding and blow molding, making high-volume production of complex parts difficult and costly.

The Challenge of Joining and Bonding

PTFE is famous for its non-stick properties, which are a result of its extremely low surface energy. This means that common adhesives have nothing to adhere to.

Achieving a strong adhesive bond requires aggressive surface preparation, such as chemical etching with powerful agents, to create microscopic anchor points for a specialized adhesive to grip. This adds significant complexity and cost to any assembly process.

The Ineffectiveness of Welding

Welding thermoplastics involves melting the surfaces of two pieces so they can flow together and form a monolithic bond upon cooling.

Because PTFE does not truly flow when melted, traditional polymer welding techniques are ineffective. The material will not mix at the interface, resulting in an extremely weak or non-existent bond.

The Go-To Fabrication Methods for PTFE

Given the limitations above, fabricating parts from PTFE relies on a completely different set of techniques, more akin to those used in metallurgy or woodworking than in plastics processing.

Compression and Sintering

This is the primary method for creating stock PTFE shapes like rods, sheets, and tubes. The process involves compressing granular PTFE powder into the desired form (a "preform") and then heating it in a controlled oven below its melting point.

This heating process, known as sintering, causes the individual polymer particles to fuse together into a solid mass.

Machining

Once a stock shape has been created through sintering, it can be machined into a final part using standard equipment like lathes and mills.

PTFE is relatively soft and machines easily, though its low thermal conductivity can lead to localized overheating. For high-precision work, chilling the material before machining can improve dimensional stability and surface finish.

Understanding the Inherent Trade-offs

Choosing PTFE for its performance means accepting several critical design and production compromises that are directly tied to its fabrication methods.

Susceptibility to Creep

PTFE is a soft material that can deform over time when subjected to a constant load, a phenomenon known as creep. This lack of sturdiness under pressure must be accounted for in the design phase, as it cannot be easily fabricated into reinforcing structures.

Sensitivity to Abrasion

While PTFE has an exceptionally low coefficient of friction, it is not highly resistant to abrasion or wear. This limits its use in applications with high-speed contact against rough surfaces.

Difficulty in Mass Production

The multi-step process of sintering and machining is inherently slower and more labor-intensive than a fully automated process like injection molding. This makes PTFE a less suitable choice for applications requiring millions of identical, low-cost parts.

Making the Right Choice for Your Application

Selecting the right material requires balancing performance needs with manufacturing realities. Consider your primary goal to determine if PTFE is the correct path.

- If your primary focus is on high-volume, complex parts: PTFE is likely a poor choice due to its incompatibility with injection molding.

- If your primary focus is on seals, gaskets, or bushings with extreme chemical resistance: PTFE is an excellent choice, provided the design can be machined from standard stock shapes.

- If your primary focus is on a structural component under constant load: Use standard PTFE with caution and consider filled grades (e.g., glass or carbon-filled PTFE) to mitigate its natural tendency to creep.

- If your primary focus is on joining multiple components: Be prepared to incorporate mechanical fasteners or invest in complex and costly surface etching processes for adhesive bonding.

Ultimately, working with PTFE means designing for its manufacturing process, not just for its exceptional material properties.

Summary Table:

| Limitation | Consequence | Common Alternative Method |

|---|---|---|

| Extremely High Melt Viscosity | Cannot be injection molded or blow molded | Compression Molding & Sintering |

| Very Low Surface Energy | Difficult to bond or glue without aggressive surface prep | Mechanical Fastening |

| Ineffective Welding | Cannot form strong monolithic bonds by melting | Machining from Sintered Shapes |

| Susceptibility to Creep | Deforms under constant load; limits structural use | Design Accommodation / Filled Grades |

Need High-Precision PTFE Components Despite the Challenges?

KINTEK specializes in overcoming the fabrication limitations of PTFE. We expertly utilize compression molding, sintering, and precision machining to manufacture custom PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Fabrication: We navigate PTFE's unique properties to deliver parts that meet your exact specifications.

- Custom Solutions: From prototypes to high-volume orders, we tailor our approach to your project's needs.

- Material Knowledge: We help you select the right PTFE grade (including filled compounds) to optimize performance and mitigate limitations like creep.

Let's engineer a solution for your most demanding applications. Contact KINTEK today to discuss your project and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments