At its core, the production of expanded PTFE (ePTFE) is a process of controlled mechanical stretching. Unlike foamed plastics, no gas or chemical blowing agent is used; instead, solid Polytetrafluoroethylene (PTFE) is physically pulled apart under precise conditions to create a strong, microporous material.

The critical insight is that ePTFE is not a different chemical, but a different physical structure of PTFE. The manufacturing process transforms solid PTFE into a microscopic web of nodes and fibrils, which is the source of its unique and valuable properties like breathability and enhanced strength.

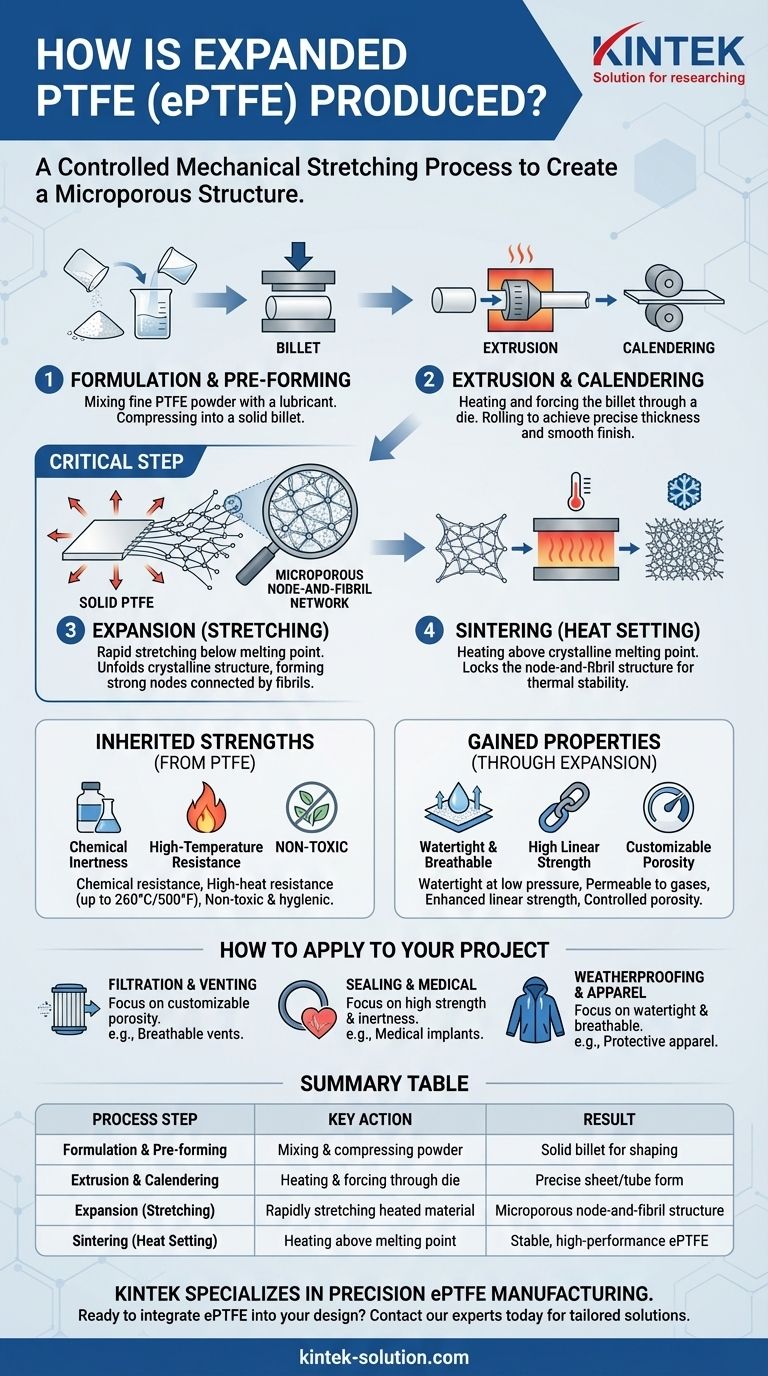

The ePTFE Manufacturing Process: A Step-by-Step Breakdown

The creation of ePTFE is a multi-stage physical transformation. Each step is designed to manipulate the molecular structure of the PTFE to achieve the desired final properties.

Step 1: Formulation and Pre-forming

The process begins by mixing fine PTFE powder with a lubricant or processing aid.

This mixture is then compressed under high pressure into a solid cylindrical shape known as a billet or preform. This initial compaction is crucial for the next stage.

Step 2: Extrusion and Calendering

The lubricated preform is heated and forced through a die in a process called extrusion. This forms the material into a basic shape, like a sheet or a tube.

The extruded shape may then be passed through rollers (calendered) to achieve a precise thickness and smooth surface finish.

Step 3: The Expansion Phase (Stretching)

This is the most critical step and is what differentiates ePTFE from standard PTFE. The material is heated again, well below its melting point, and stretched rapidly in one or more directions.

This rapid stretching does not break the material. Instead, it causes the crystalline structure of the PTFE to unfold and form a network of solid nodes connected by extremely thin, strong fibers called fibrils.

Step 4: Sintering (Heat Setting)

After stretching, the newly formed microporous structure is unstable. The material is heated to a temperature above the crystalline melting point of the PTFE (a process known as sintering) and then cooled.

This heat treatment locks the node-and-fibril structure into place, creating a thermally stable material that will not shrink or change its shape.

Why This Process Unlocks Unique Properties

The expansion process fundamentally re-engineers the material's physical form, giving it capabilities that solid PTFE lacks while retaining its core chemical advantages.

Inherited Strengths from PTFE

The base material is still PTFE, so ePTFE retains its outstanding chemical inertness and resistance to nearly all chemicals.

It also keeps its high-temperature resistance, capable of performing continuously at temperatures up to 260°C (500°F), along with its non-toxic and hygienic properties.

Properties Gained Through Expansion

The creation of the node-and-fibril network is the source of ePTFE's new benefits.

The microscopic pores make the material watertight at low pressure but permeable to gases, enabling its use in breathable vents and waterproof-breathable fabrics. The size of these pores can be precisely controlled by adjusting the stretching parameters, resulting in customizable porosity (low, medium, or high density).

The fibrils give the material exceptional linear strength, making it far stronger and more creep-resistant than its non-expanded counterpart.

How to Apply This to Your Project

Understanding the manufacturing process helps you specify the right material for your goal.

- If your primary focus is filtration or venting: The customizable porosity, controlled during the expansion phase, is the most critical property to define for your application.

- If your primary focus is high-strength seals or medical implants: The high linear strength created by the fibrillated structure, combined with PTFE's chemical inertness, is the key advantage.

- If your primary focus is weatherproofing or protective apparel: The combination of being watertight while remaining breathable—a direct result of the microporous structure—is the central benefit.

By grasping how ePTFE is made, you can better leverage its unique structure to solve complex engineering challenges.

Summary Table:

| Process Step | Key Action | Result |

|---|---|---|

| Formulation & Pre-forming | Mixing PTFE powder with a lubricant and compressing it. | Creates a solid billet ready for shaping. |

| Extrusion & Calendering | Heating and forcing the billet through a die, then rolling it. | Forms the material into a precise sheet or tube. |

| Expansion (Stretching) | Rapidly stretching the heated material. | Forms the microporous node-and-fibril structure. |

| Sintering (Heat Setting) | Heating above the melting point to lock the structure. | Creates a stable, high-performance ePTFE material. |

Leverage the unique properties of ePTFE for your application.

Now that you understand how expanded PTFE is made, you can see its potential for solving complex challenges in filtration, sealing, medical devices, and protective apparel.

KINTEK specializes in the precision manufacturing of PTFE and ePTFE components. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for porosity, strength, and chemical resistance.

Ready to integrate ePTFE into your design? Contact our experts today to discuss how our tailored solutions can enhance your product's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers