The primary factors to consider when choosing a filler for PTFE are the specific application requirements for mechanical strength, wear resistance, thermal properties, and chemical compatibility. Selecting the right filler is a process of tailoring the base PTFE material to overcome its inherent limitations and excel in a specific operating environment.

Pure PTFE is an exceptional material for its chemical inertness and low friction, but it often lacks the structural integrity for demanding applications. Fillers are not merely additives; they are functional components that transform PTFE into a high-performance material engineered for a specific purpose.

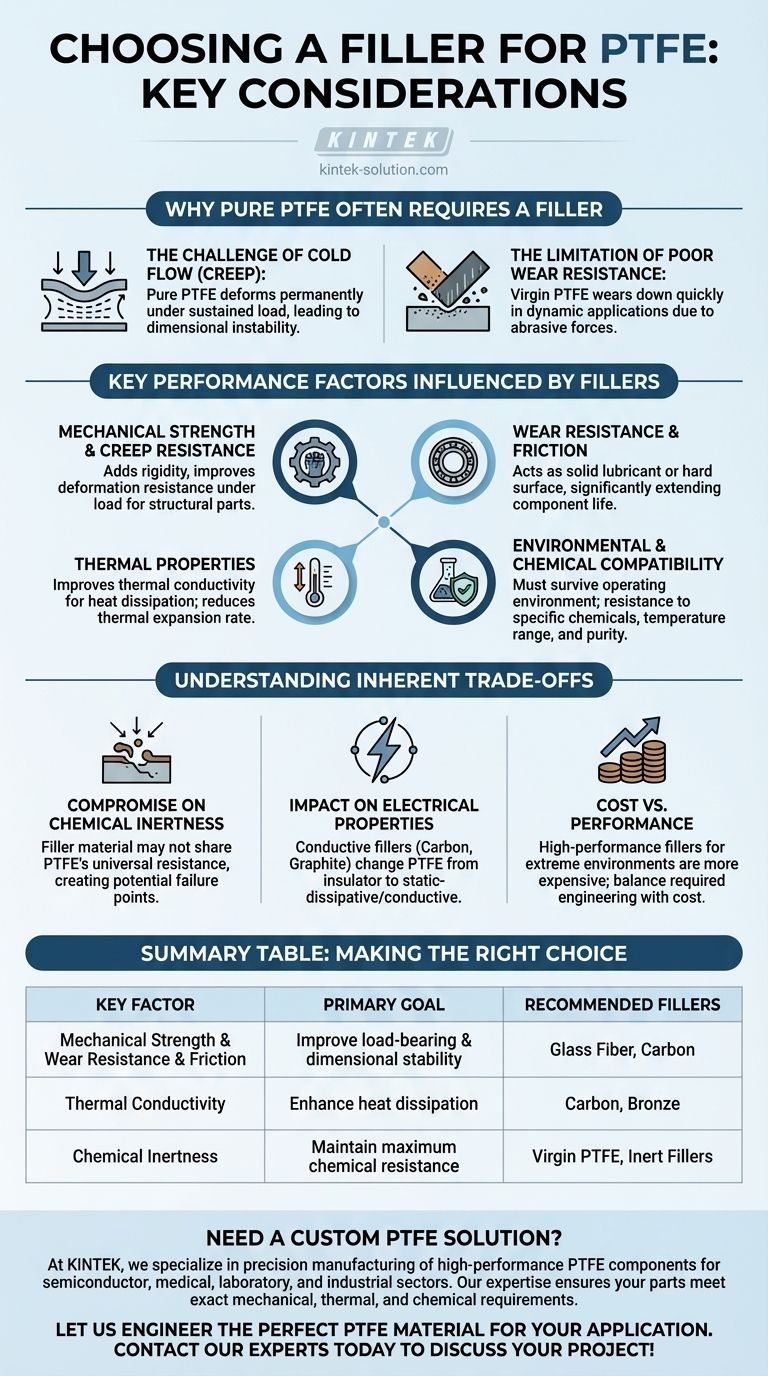

Why Pure PTFE Often Requires a Filler

Unfilled, or "virgin," PTFE is a soft material. While this makes it highly conformable for applications like seals, it also makes it susceptible to two major weaknesses.

The Challenge of Cold Flow (Creep)

Cold flow, or creep, is the tendency of a material to deform permanently under a sustained load, even at room temperature. Pure PTFE has poor creep resistance, meaning it will slowly change shape when compressed, which is a significant issue for gaskets and structural components that need to maintain dimensional stability.

The Limitation of Poor Wear Resistance

In dynamic applications involving friction, such as bearings or piston rings, virgin PTFE wears down very quickly. Its soft nature does not hold up well to abrasive forces, leading to a short service life.

Key Performance Factors Influenced by Fillers

Adding a filler is a strategic decision to enhance one or more of PTFE's properties. The choice depends entirely on which performance characteristic is most critical for your application.

Mechanical Strength and Creep Resistance

This is the most common reason to add a filler. By introducing a harder, more rigid material into the PTFE matrix, you dramatically improve its ability to resist deformation under load. This is essential for any structural or high-pressure sealing application.

Wear Resistance and Friction

For moving parts, improving wear resistance is critical. Certain fillers act as a solid lubricant or simply provide a harder surface, significantly extending the component's life. While fillers can slightly increase the coefficient of friction compared to virgin PTFE, the trade-off is almost always a massive gain in durability.

Thermal Properties

Fillers can significantly alter how filled PTFE responds to heat. They can improve thermal conductivity, allowing the material to dissipate heat away from friction points more effectively. They also reduce the thermal expansion rate, ensuring the component remains dimensionally stable across a wider temperature range.

Environmental and Chemical Compatibility

The filler must be able to survive the operating environment. You must consider its resistance to the specific chemicals it will encounter, its suitability for the required temperature range, and any purity requirements for industries like food processing or medical devices.

Understanding the Inherent Trade-offs

There is no universal solution, and every filler introduces a compromise. Understanding these trade-offs is fundamental to making the right choice.

The Compromise on Chemical Inertness

One of PTFE's most valued properties is its near-universal chemical resistance. However, the filler material itself may not share this quality. A filler can create a point of failure if it is attacked by a chemical that pure PTFE would easily resist.

The Impact on Electrical Properties

Virgin PTFE is an excellent electrical insulator. Many common fillers, such as carbon and graphite, are electrically conductive. Adding them will change the material's properties from an insulator to a static-dissipative or conductive material.

Cost vs. Performance

The cost of the final material is directly influenced by the type and percentage of filler used. High-performance fillers designed for extreme environments will be more expensive. You must balance the required engineering performance against the cost-effectiveness of the material.

Making the Right Choice for Your Goal

Your selection should be driven by the single most important performance demand of your application.

- If your primary focus is creep resistance and load-bearing: Choose a filler that adds rigidity and structural integrity, like glass fiber or carbon.

- If your primary focus is wear resistance in dynamic seals or bearings: Choose a filler known for its durability and low friction, such as graphite or bronze.

- If your primary focus is thermal conductivity: Select a filler that excels at heat dissipation, like carbon or bronze.

- If your primary focus is maintaining maximum chemical resistance: Use virgin PTFE or a material with a highly inert filler that is proven to be compatible with your specific chemical environment.

Ultimately, selecting the right filler transforms PTFE from a general-purpose polymer into a precision-engineered component designed for success.

Summary Table:

| Key Factor | Primary Goal | Recommended Fillers |

|---|---|---|

| Mechanical Strength & Creep Resistance | Improve load-bearing & dimensional stability | Glass Fiber, Carbon |

| Wear Resistance & Friction | Extend life in dynamic applications | Graphite, Bronze |

| Thermal Conductivity | Enhance heat dissipation | Carbon, Bronze |

| Chemical Inertness | Maintain maximum chemical resistance | Virgin PTFE, Inert Fillers |

Need a Custom PTFE Solution?

At KINTEK, we specialize in precision manufacturing of high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom filler selection and fabrication ensures your parts meet exact mechanical, thermal, and chemical requirements—from prototypes to high-volume production.

Let us engineer the perfect PTFE material for your application. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection