In high-performance sealing, a Polytetrafluoroethylene (PTFE) oil seal is a specialized component engineered for environments where standard rubber seals would quickly fail. What makes PTFE seals unique is their material composition—a fluoropolymer with exceptionally strong carbon-fluorine bonds—which grants them an unparalleled combination of chemical inertness, extreme temperature stability, and a very low-friction surface.

PTFE oil seals are not a universal upgrade over traditional elastomer seals. They are a purpose-built solution for demanding applications where the high cost is justified by their superior performance under conditions of extreme heat, aggressive chemicals, or high operational speeds.

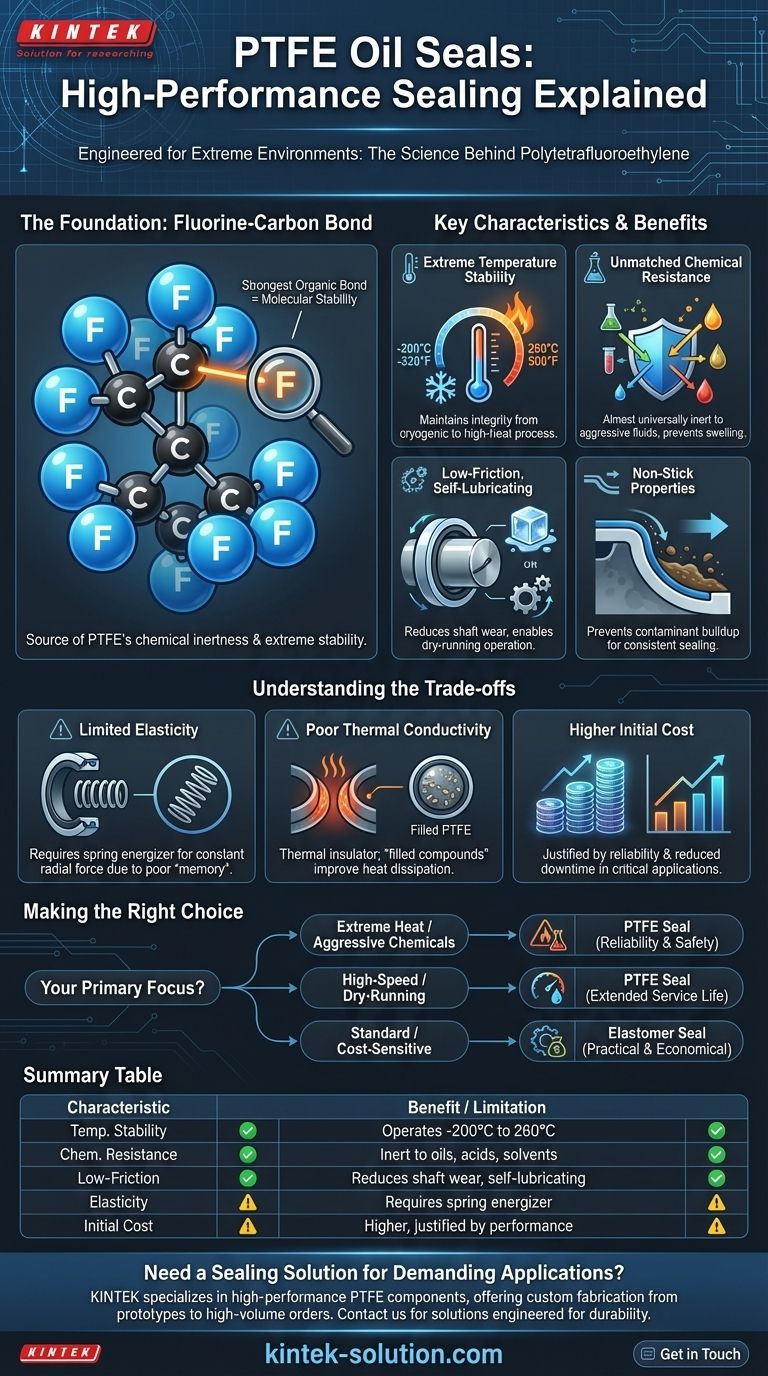

The Foundation: Why PTFE is Different

The remarkable properties of PTFE all originate from its unique molecular structure. Understanding this is key to understanding its practical applications.

The Power of the Fluorine-Carbon Bond

At its core, PTFE is a polymer with a simple backbone of carbon atoms completely shielded by fluorine atoms.

The bond between carbon and fluorine is exceptionally strong and stable. This molecular stability is the direct source of PTFE's signature characteristics.

Key Characteristics of PTFE Seals

These fundamental properties translate into tangible benefits in demanding industrial and mechanical applications.

Extreme Temperature Stability

PTFE seals operate effectively across a vast temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This allows them to maintain their integrity and sealing capability in applications involving cryogenic liquids or high-temperature engine and industrial processes where most elastomers would become brittle or degrade.

Unmatched Chemical Resistance

The stable molecular structure makes PTFE almost universally inert.

It can withstand exposure to a wide array of aggressive fluids, including oils, acids, solvents, and bases, that would cause conventional rubber seals to swell, soften, or dissolve.

Low-Friction, Self-Lubricating Surface

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice.

This self-lubricating property reduces wear on the rotating shaft, minimizes heat generation, and allows the seal to function effectively in dry-running or minimally lubricated conditions.

Non-Stick Properties

The material's non-stick surface prevents contaminants, sludge, or other media from adhering to the seal lip. This ensures the seal maintains a clean, effective contact point with the shaft, preventing premature wear and failure.

Understanding the Trade-offs

While powerful, PTFE is not without its limitations. Acknowledging these trade-offs is critical for proper application.

Limited Elasticity

Compared to rubber, PTFE is a relatively rigid material with poor "memory." It does not spring back into shape as readily after being deformed.

To counteract this, many PTFE seals incorporate a metal spring energizer that provides the constant radial force needed to maintain a tight seal against the shaft.

Poor Thermal Conductivity

PTFE is a thermal insulator, meaning it does not dissipate heat well. In very high-speed applications, friction can cause heat to build up at the sealing point.

This is often mitigated by using filled PTFE compounds, which include additives like copper or graphene to improve thermal conductivity.

Higher Initial Cost

PTFE seals are significantly more expensive to manufacture than their common elastomer counterparts.

Their use is justified in critical applications where the cost of seal failure—in terms of equipment damage, downtime, and safety—far exceeds the initial investment in a more durable component.

Making the Right Choice for Your Application

Selecting the correct seal material is a strategic engineering decision based on operating conditions and performance requirements.

- If your primary focus is reliability in extreme heat or with aggressive chemicals: A PTFE seal is often the only viable option, and its cost is justified by preventing catastrophic system failure.

- If your primary focus is high-speed or dry-running applications: The self-lubricating nature of PTFE is a key advantage, extending the service life of both the seal and the equipment.

- If your primary focus is a standard, cost-sensitive application with moderate temperatures and non-aggressive fluids: A conventional elastomer seal remains the more practical and economical choice.

Ultimately, choosing a PTFE seal is a decision to engineer for durability and reliability where other materials simply cannot perform.

Summary Table:

| Key Characteristic | Benefit / Limitation |

|---|---|

| Extreme Temperature Stability | Operates from -200°C to 260°C (-328°F to 500°F) |

| Unmatched Chemical Resistance | Inert to oils, acids, solvents, and bases |

| Low-Friction & Self-Lubricating | Reduces shaft wear, suitable for dry-running conditions |

| Limited Elasticity | Often requires a metal spring energizer for proper sealing force |

| Higher Initial Cost | Justified by superior performance and reliability in critical applications |

Need a Sealing Solution for Demanding Applications?

If your operations involve extreme temperatures, aggressive chemicals, or high-speed environments, a standard seal may not be enough. KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a seal engineered for durability and reliability.

Contact us today to discuss how our PTFE seals can solve your most challenging sealing problems: Get in Touch

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions