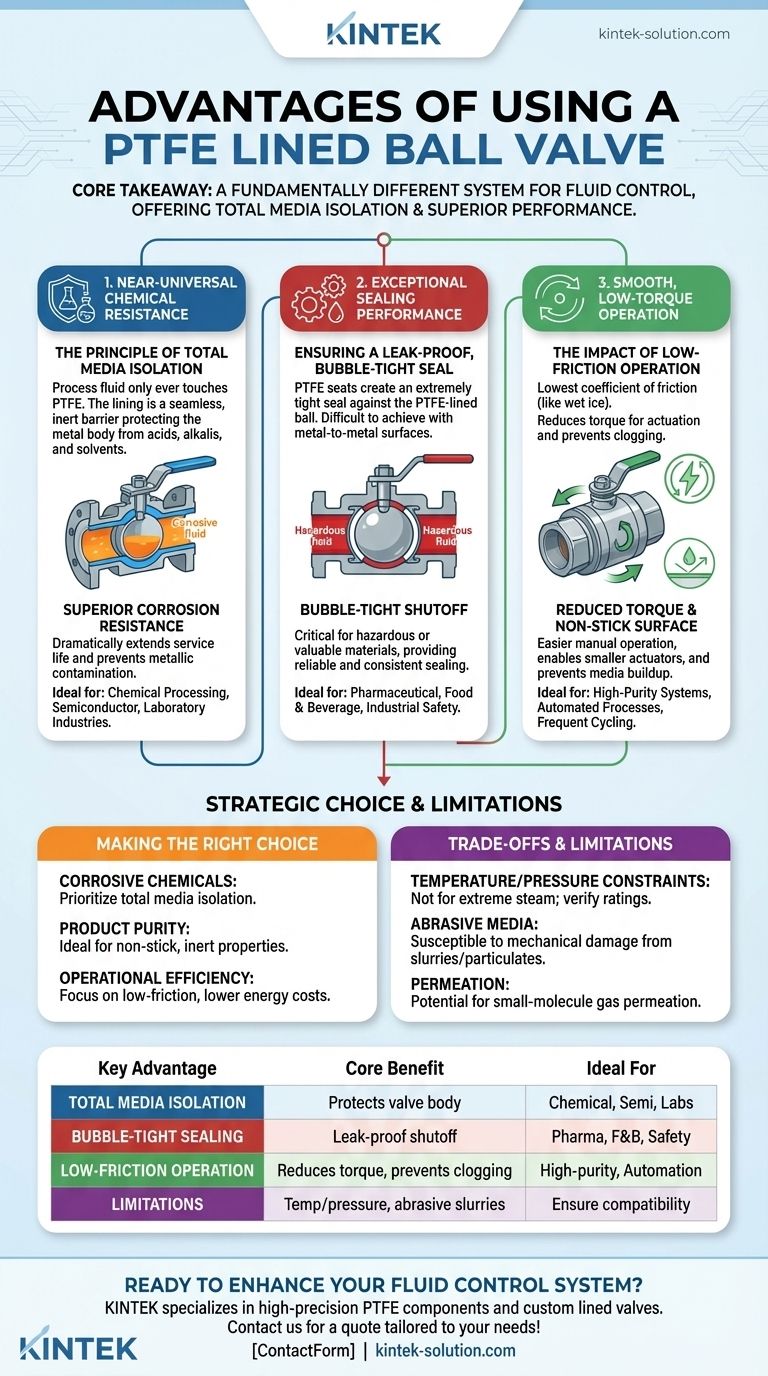

At its core, a PTFE lined ball valve offers three primary advantages: near-universal chemical resistance, exceptional sealing performance, and smooth, low-torque operation. By encasing the valve's internal components in an inert Polytetrafluoroethylene (PTFE) layer, it effectively isolates corrosive or high-purity media from the valve's metal body, ensuring both system longevity and fluid integrity.

The crucial takeaway is that a PTFE lined valve isn't just a component with a protective coating; it is a fundamentally different system for fluid control. It creates a completely inert, non-stick, and low-friction flow path, making it the default choice for safely handling the most aggressive and sensitive industrial fluids.

How a PTFE Lining Transforms Valve Performance

A standard metal ball valve is vulnerable to chemical attack and wear. The addition of a PTFE lining addresses these failure points directly, transforming the valve's capability and reliability in demanding environments.

The Principle of Total Media Isolation

The defining feature of this valve is that the process fluid only ever touches PTFE. The lining acts as a seamless, chemically inert barrier protecting the structural metal body (typically carbon or stainless steel) from acids, alkalis, solvents, and other aggressive chemicals.

This isolation is the source of its superior corrosion resistance, which dramatically extends the valve's service life and prevents metallic contamination of the process media.

Ensuring a Leak-Proof, Bubble-Tight Seal

PTFE is a relatively soft and pliable material. The valve seats, also made of PTFE, create an extremely tight seal against the PTFE-lined ball when the valve is closed.

This design ensures bubble-tight shutoff, a critical requirement for preventing leaks of hazardous or valuable materials. It provides a reliable and consistent sealing performance that is difficult to achieve with metal-to-metal seating surfaces.

The Impact of Low-Friction Operation

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This property has two major operational benefits.

First, it reduces the torque required to open and close the valve, making manual operation easier and allowing for smaller, more energy-efficient actuators in automated systems.

Second, its non-stick surface prevents media from building up or adhering to the ball and body. This ensures smooth flow, prevents clogging, and makes the valve ideal for high-purity applications where cleanliness is paramount.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined valves are not a universal solution. Understanding their limitations is critical for proper application.

Temperature and Pressure Constraints

PTFE has a distinct operating temperature range. It is not suitable for extremely high-temperature services, such as high-pressure steam, where the lining can degrade or fail. Always verify the manufacturer's pressure-temperature rating against your specific process conditions.

Susceptibility to Abrasive Media

PTFE is a soft polymer. It is not designed for abrasive slurries or fluids containing hard particulates. These materials can mechanically damage the lining through erosion or scoring, leading to premature failure and loss of corrosion resistance.

Potential for Permeation

While excellent as a liquid barrier, PTFE can be permeable to certain small-molecule gases (like hydrogen or helium) over time, especially at higher temperatures. This is a crucial consideration for very high-vacuum or specific gas containment applications where zero permeation is required.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its core strengths to your primary operational goal.

- If your primary focus is handling highly corrosive chemicals: The complete media isolation from the PTFE lining is the single most important advantage, providing unmatched protection for the valve's structural components.

- If your primary focus is maintaining product purity: The inert, non-stick nature of the lining is ideal for food, beverage, and pharmaceutical applications, as it prevents contamination and media buildup.

- If your primary focus is operational efficiency: The low-friction design reduces wear and requires less energy for actuation, leading to a lower total cost of ownership over the valve's extended lifespan.

Ultimately, choosing a PTFE lined ball valve is a strategic decision to ensure system integrity, purity, and reliability when controlling challenging fluids.

Summary Table:

| Key Advantage | Core Benefit | Ideal For |

|---|---|---|

| Total Media Isolation | Protects valve body from corrosive acids, alkalis, and solvents. | Chemical processing, semiconductor, and laboratory industries. |

| Bubble-Tight Sealing | Ensures leak-proof shutoff for hazardous or high-purity media. | Pharmaceutical, food & beverage, and industrial safety applications. |

| Low-Friction Operation | Reduces torque, prevents clogging, and enables easy actuation. | High-purity systems, automated processes, and frequent cycling needs. |

| Limitations to Consider | Temperature/pressure constraints; not for abrasive slurries. | Ensure compatibility with your specific process conditions. |

Ready to enhance your fluid control system's integrity and reliability?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, labware, and custom PTFE lined ball valves—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your valves deliver unmatched corrosion resistance, purity, and performance.

Whether you need a custom prototype or high-volume production, we provide solutions tailored to your exact requirements. Contact us today to discuss your application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech