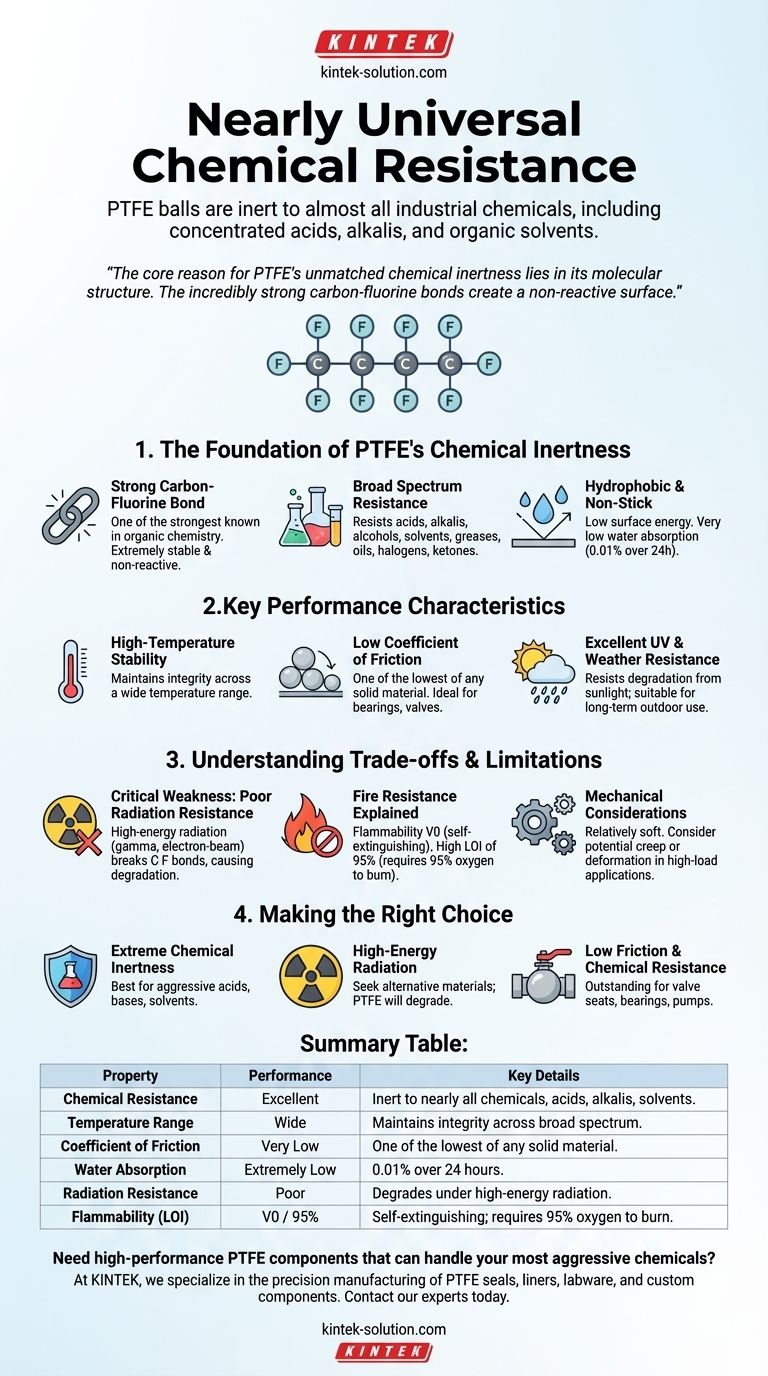

In short, Polytetrafluoroethylene (PTFE) balls exhibit nearly universal chemical resistance. They are inert to almost all industrial chemicals, including concentrated acids, alkalis, and organic solvents. This exceptional performance is their defining characteristic, making them a default material choice for the most demanding chemical environments.

The core reason for PTFE's unmatched chemical inertness lies in its molecular structure. The incredibly strong carbon-fluorine bonds create a non-reactive surface, but this singular strength comes with specific trade-offs, particularly a notable weakness to high-energy radiation.

The Foundation of PTFE's Chemical Inertness

The exceptional resistance of PTFE is not a surface treatment; it is an inherent property of the material itself. Understanding why it is so robust is key to using it effectively.

The Power of the Carbon-Fluorine Bond

The molecular structure of PTFE consists of a chain of carbon atoms completely shielded by a sheath of fluorine atoms. The bond between carbon and fluorine is one of the strongest known in organic chemistry.

This powerful bond makes the molecule extremely stable and non-reactive, preventing other chemicals from breaking it down or forming new connections.

A Broad Spectrum of Resistance

Because of its stable structure, PTFE is resistant to a vast range of substances. This includes concentrated and dilute acids, alkalis, alcohols, and various organic solvents.

It also effectively resists greases, oils, halogens, and ketones. Critically, there is no known solvent at room temperature that can dissolve PTFE.

Hydrophobic and Non-Stick Properties

This chemical inertness also results in very low surface energy. This means other substances, including water, are not attracted to its surface, leading to excellent hydrophobic (water-repelling) and non-stick properties.

PTFE has extremely low water absorption, registering just 0.01% over a 24-hour period.

Key Performance Characteristics

While chemical resistance is its primary feature, other properties make PTFE a unique engineering material.

High-Temperature Stability

PTFE maintains its integrity and properties across a wide range of temperatures. This allows it to be used in applications involving both chemical exposure and significant heat.

Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This makes it an excellent choice for ball bearings, check valves, and other applications where smooth, low-resistance movement is required.

Excellent UV and Weather Resistance

The material shows excellent resistance to degradation from ultraviolet (UV) radiation from sunlight. This, combined with its hydrophobic nature, makes it highly suitable for long-term outdoor applications.

Understanding the Trade-offs and Limitations

No material is perfect for every application. While PTFE excels in chemical resistance, its limitations are equally important to understand for proper material selection.

Critical Weakness: Poor Radiation Resistance

This is PTFE's most significant vulnerability. Exposure to high-energy radiation, such as gamma or electron-beam radiation, will break the carbon-fluorine bonds.

This degradation causes the material to become brittle and lose its mechanical properties, making it unsuitable for applications in nuclear or high-radiation environments.

Fire Resistance Explained

PTFE has a flammability rating of V0, meaning it self-extinguishes within 10 seconds after the flame source is removed.

It also has a very high Limiting Oxygen Index of 95%. This means it requires an atmosphere of 95% oxygen to support combustion, making it extremely difficult to burn in normal air.

Mechanical Considerations

While chemically robust, PTFE is a relatively soft material compared to metals or ceramics. In high-load mechanical applications, its potential for creep or deformation must be considered.

Making the Right Choice for Your Application

Selecting the correct material requires balancing its strengths against the specific demands of your environment.

- If your primary focus is extreme chemical inertness: PTFE is one of the best and most reliable choices available for handling aggressive acids, bases, and solvents.

- If your application involves high-energy radiation: You must seek an alternative material, as PTFE's molecular structure will degrade and fail in this environment.

- If you need a combination of low friction and chemical resistance: PTFE is an outstanding candidate for components like valve seats, bearings, and pumps in corrosive systems.

Ultimately, leveraging PTFE successfully means deploying it where its unparalleled chemical stability is the solution and avoiding environments that exploit its few weaknesses.

Summary Table:

| Property | Performance | Key Details |

|---|---|---|

| Chemical Resistance | Excellent | Inert to nearly all industrial chemicals, acids, alkalis, and solvents. No known solvent dissolves it at room temperature. |

| Temperature Range | Wide | Maintains integrity across a broad temperature spectrum. |

| Coefficient of Friction | Very Low | One of the lowest of any solid material. |

| Water Absorption | Extremely Low | 0.01% over 24 hours. |

| Radiation Resistance | Poor | Degrades under high-energy radiation (gamma, electron-beam). |

| Flammability (LOI) | V0 / 95% | Self-extinguishing; requires 95% oxygen to burn. |

Need high-performance PTFE components that can handle your most aggressive chemicals?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver the unmatched chemical resistance and reliability your application demands, from prototypes to high-volume production.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What types of fillers can be used to enhance PTFE lip seals? Boost Performance for Demanding Applications

- How is a piston seal constructed? A Guide to Dynamic, Pressure-Energized Sealing

- What are some common uses of PTFE in industries? Solve Challenges with a Versatile High-Performance Polymer

- What are critical installation practices for PTFE O-rings? Avoid Leaks and Ensure a Perfect Seal

- What are the key properties of PTFE that make it suitable for bearing pads? Achieve Superior Load Management

- What should be considered when milling Teflon? Master Machining for Precision PTFE Parts

- What industries benefit from using PTFE gaskets in ball valves? Ensure Purity & Reliability in Critical Processes

- What is the best PTFE material for cryogenic gas applications? mPTFE Ensures Leak-Proof Sealing