When failure is not an option, specific industries consistently rely on Polytetrafluoroethylene (PTFE) gaskets. The most prominent beneficiaries are chemical processing, pharmaceutical and medical manufacturing, food and beverage production, and electronics. These sectors choose PTFE for its unparalleled ability to maintain seal integrity in environments where other materials would quickly degrade and fail.

The decision to use a PTFE gasket is not just about choosing a material; it's about managing risk. PTFE's value comes from its ability to maintain a seal in environments—chemically aggressive, high-purity, or extreme temperature—where contamination or leakage is unacceptable.

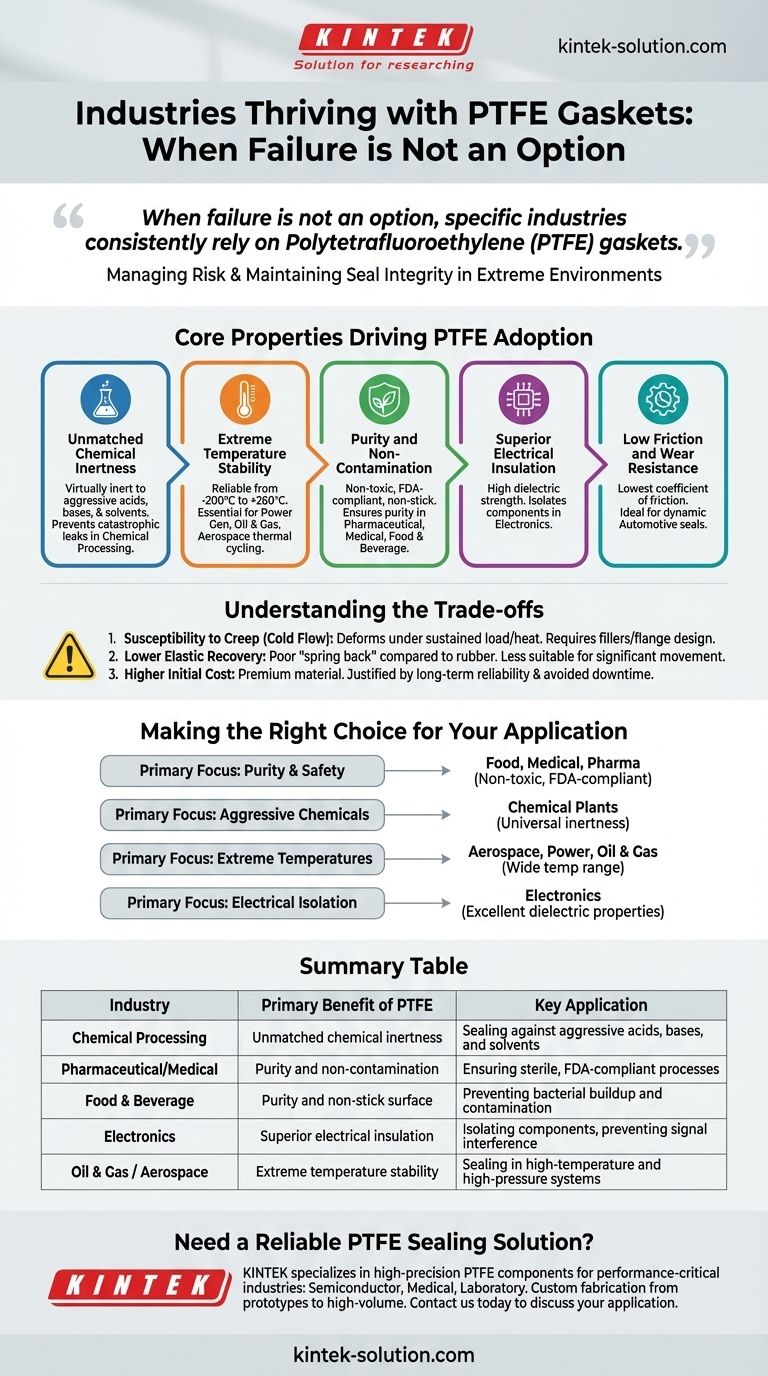

The Core Properties Driving PTFE Adoption

The widespread use of PTFE is not accidental. It is a direct result of a unique combination of physical and chemical properties that solve critical engineering challenges. Different industries prioritize different properties.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive acids, bases, and solvents. This makes it an essential material in the chemical processing industry.

Where a standard elastomer gasket would dissolve or swell upon contact with corrosive media, a PTFE gasket maintains its form and sealing capability, preventing catastrophic leaks and ensuring process safety.

Extreme Temperature Stability

PTFE gaskets perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This stability is critical for applications in power generation (high-pressure steam), oil and gas (high-temperature extraction), and aerospace, where components must endure drastic thermal cycling.

Purity and Non-Contamination

In the pharmaceutical, medical, and food and beverage industries, preventing product contamination is the primary goal. PTFE is non-toxic, physiologically inert, and available in FDA-compliant grades.

Its non-stick surface also resists bacterial buildup and is easy to clean and sterilize, ensuring the purity of the end product.

Superior Electrical Insulation

PTFE has an extremely high dielectric strength, meaning it is an excellent electrical insulator. This property is the main reason it is heavily used in the electronics industry.

It is used to isolate components, prevent signal interference, and provide durable seals in sensitive electronic enclosures.

Low Friction and Wear Resistance

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is valuable in dynamic applications.

In the automotive industry, it is used for seals in engine and transmission components that must withstand constant movement and wear.

Understanding the Trade-offs of PTFE

While highly capable, PTFE is not a universal solution. An objective assessment requires understanding its limitations to prevent misapplication.

Susceptibility to Creep (Cold Flow)

Under sustained compressive load, especially at elevated temperatures, PTFE can slowly deform. This phenomenon, known as creep or cold flow, can reduce sealing pressure over time.

Engineers must account for this by using fillers (like glass or carbon) in the PTFE or by ensuring proper flange design and bolt torque procedures.

Lower Elastic Recovery

Compared to rubber or elastomeric gaskets, pure PTFE has poor elastic memory. It does not "spring back" as effectively after being compressed.

This makes it less suitable for applications involving significant flange movement, vibration, or frequent pressure cycles, as it may not be able to maintain a consistent seal.

Higher Initial Cost

High-performance materials come at a premium. PTFE gaskets are generally more expensive than common elastomeric gaskets.

The decision to use PTFE must be justified by the total cost of ownership, where its reliability and long service life prevent costly downtime, product loss, or safety incidents.

Making the Right Choice for Your Application

Selecting the correct gasket material requires matching its properties to the demands of your specific environment and operational goals.

- If your primary focus is process purity and safety: PTFE's non-toxic, FDA-compliant, and non-stick properties make it the default choice for food, medical, and pharmaceutical applications.

- If your primary focus is handling aggressive chemicals: PTFE's near-universal chemical inertness provides the most reliable seal against corrosive media in chemical plants.

- If your primary focus is performance in extreme temperatures: The wide operating temperature range of PTFE ensures seal integrity in aerospace, power generation, and oil and gas systems.

- If your primary focus is electrical isolation: PTFE's excellent dielectric properties are critical for preventing shorts and ensuring signal integrity in electronics.

Ultimately, understanding these core properties allows you to select a sealing solution based on engineering requirements, not just industry convention.

Summary Table:

| Industry | Primary Benefit of PTFE | Key Application |

|---|---|---|

| Chemical Processing | Unmatched chemical inertness | Sealing against aggressive acids, bases, and solvents |

| Pharmaceutical/Medical | Purity and non-contamination | Ensuring sterile, FDA-compliant processes |

| Food & Beverage | Purity and non-stick surface | Preventing bacterial buildup and contamination |

| Electronics | Superior electrical insulation | Isolating components and preventing signal interference |

| Oil & Gas / Aerospace | Extreme temperature stability | Sealing in high-temperature and high-pressure systems |

Need a Reliable PTFE Sealing Solution?

When failure is not an option, the right material makes all the difference. KINTEK specializes in manufacturing high-precision PTFE components, including gaskets, seals, liners, and custom labware.

We serve industries where performance is critical:

- Semiconductor and Electronics for superior insulation.

- Medical and Pharmaceutical for guaranteed purity.

- Laboratory and Industrial for chemical resistance and temperature stability.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders. Let us help you manage risk and ensure process integrity.

Contact KINTEK today to discuss your specific application and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do high PV grades of PTFE perform in demanding applications? Excel in High-Speed, High-Load Environments

- What are the operating conditions where PTFE slide bearings perform best? Optimize for High Load & Low Speed

- What makes PTFE gaskets suitable for the food industry? Ensure Purity and Compliance

- What are the benefits of carbon-filled PTFE bushes? Boost Strength & Wear Resistance for Demanding Applications

- What is the importance of selecting the right ball valve seat materials? Ensure a Leak-Proof Seal

- What advantages do PTFE bearings offer in aviation systems? Achieve Lighter, More Reliable Aircraft Performance

- What are the key properties that make PTFE gaskets suitable for industrial applications? | KINTEK

- What role do Teflon PTFE sheets play in sewing projects? Achieve Flawless, Professional Results