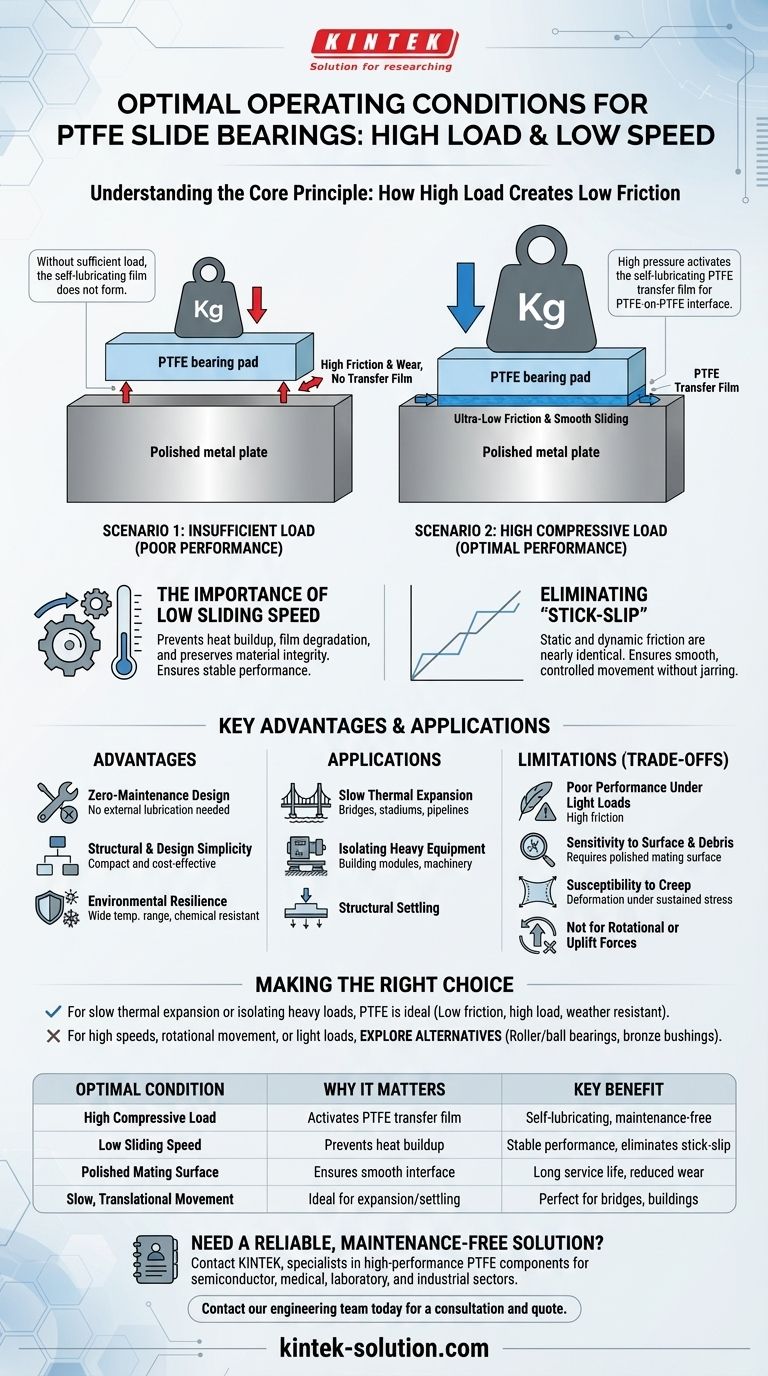

In short, PTFE slide bearings perform best under conditions of high compressive load and low sliding speed. This specific environment is critical because the high pressure forces a microscopic, self-lubricating film of PTFE material onto the mating surface, creating an ultra-low-friction interface. Without sufficient load, this transfer film does not form correctly, and the bearing's primary advantage is lost.

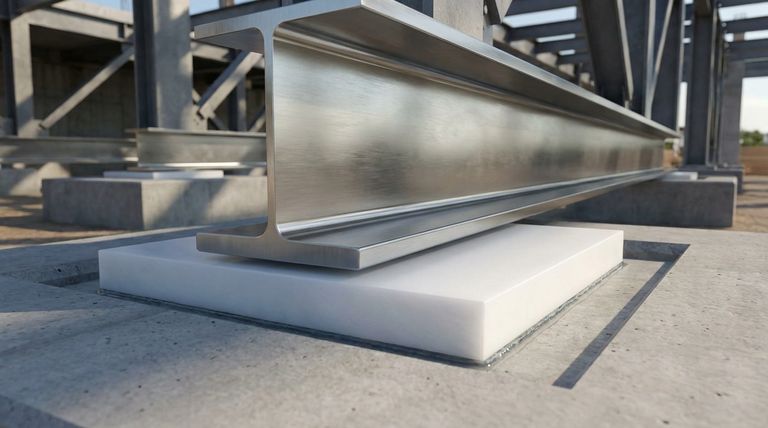

The core challenge is not simply finding a low-friction material, but understanding the specific mechanics that make it work. PTFE slide bearings are a specialized solution engineered for slow, heavy, translational movements, particularly in applications where ongoing maintenance is impractical or impossible.

The Core Principle: How High Load Creates Low Friction

PTFE's remarkable properties are not inherent in all situations; they must be activated. The combination of high load and low speed creates the perfect environment for this to happen.

Activating the Self-Lubricating Film

Under a significant compressive load, a microscopic layer of the PTFE material physically transfers from the bearing pad to the opposing polished metal plate. This creates a PTFE-on-PTFE sliding interface.

This molecular transfer is the key to its performance. The friction is no longer between PTFE and steel, but between two layers of PTFE, which have one of the lowest coefficients of friction of any solid material pairing.

The Importance of Low Speed

PTFE bearings are designed for slow movements, such as the thermal expansion of a bridge or the gradual settling of a building. High speeds generate friction and heat.

Excessive heat can negatively impact the integrity of the PTFE and degrade the transfer film, leading to increased wear and a higher coefficient offriction. Low speeds ensure the system remains thermally stable.

Eliminating "Stick-Slip"

"Stick-slip" is the jerky motion that occurs when the static friction (the force needed to start moving) is significantly higher than the dynamic friction (the force needed to keep moving).

PTFE's static and dynamic coefficients of friction are nearly identical. This ensures that movement starts smoothly and without jarring, which is critical for preserving the integrity of large, heavy structures.

Key Advantages in the Right Application

When used within their ideal operating parameters, PTFE bearings offer a powerful combination of performance and simplicity.

Zero-Maintenance Design

Due to its chemical inertness, PTFE is highly resistant to weathering, corrosion, and a vast range of chemicals. It requires no external lubrication, making it an ideal "fit and forget" solution for inaccessible locations.

Structural and Design Simplicity

These bearings are mechanically simple, consisting of little more than a PTFE pad and a polished plate. This makes them cost-effective, compact, and easy to fabricate and install compared to more complex mechanical bearing assemblies.

Environmental Resilience

PTFE performs reliably across a very wide temperature range without becoming brittle or degrading. This, combined with its chemical resistance, makes it suitable for the most demanding outdoor and industrial environments.

Secondary Benefits

In addition to their primary function, PTFE bearings offer excellent electrical and thermal insulation. They also provide a degree of vibration damping, which can help isolate structures from transmitted noise and shock.

Understanding the Trade-offs and Limitations

To use PTFE bearings effectively, you must also understand their limitations. They are a specialized tool, not a universal solution.

The "High Load" Requirement

Performance is poor under light loads. If the pressure is too low to create the PTFE transfer film, the coefficient of friction will be significantly higher, and the primary benefit of the bearing is lost.

Sensitivity to Surface and Debris

Optimal performance requires the mating metal surface to be highly polished (typically a mirror-finish stainless steel). Scratches or imperfections increase friction.

While PTFE can embed very small dust particles, larger debris can get trapped between the surfaces, scoring the polish and compromising the entire system. Periodic inspection to ensure the slide path is clear is a practical necessity.

Susceptibility to Creep

Creep is the tendency of a solid material to deform permanently under the influence of sustained stress. While designed for high loads, an excessive or poorly calculated load can cause the PTFE to slowly "flow" or deform over time, altering the bearing's dimensions. Fillers (like glass or carbon) are often added to PTFE to improve creep resistance.

Purely Translational Movement

Standard PTFE slide bearings are designed to permit sliding movement in one or two dimensions and support vertical loads. They are not designed to handle significant rotational forces or uplift (tension).

Making the Right Choice for Your Goal

To determine if a PTFE slide bearing is the correct choice, consider your primary engineering objective.

- If your primary focus is accommodating slow thermal expansion in large structures (bridges, stadiums, pipelines): PTFE is an ideal solution due to its low static friction, high load capacity, and exceptional weather resistance.

- If your primary focus is isolating heavy equipment or building modules to allow for slight, slow movement: PTFE's high load capacity and simple, maintenance-free design are highly beneficial.

- If your application involves high speeds, rotational movement, or light loads: You should explore alternative bearing technologies like roller bearings, ball bearings, or externally lubricated bronze bushings.

By understanding these core principles, you can confidently specify PTFE bearings for applications where they will deliver unmatched performance and longevity.

Summary Table:

| Optimal Condition | Why It Matters | Key Benefit |

|---|---|---|

| High Compressive Load | Activates PTFE transfer film for ultra-low friction | Self-lubricating, maintenance-free operation |

| Low Sliding Speed | Prevents heat buildup and film degradation | Stable performance, eliminates stick-slip |

| Polished Mating Surface | Ensures smooth, consistent sliding interface | Long service life, reduced wear |

| Slow, Translational Movement | Ideal for thermal expansion and structural settling | Perfect for bridges, buildings, and heavy equipment |

Need a reliable, maintenance-free bearing solution for your high-load, low-speed application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom slide bearings, seals, and liners. Our expertise ensures your bearings are engineered to deliver optimal performance under the exact conditions described—activating that critical self-lubricating film for smooth, long-lasting operation.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders. Let us help you design the perfect PTFE solution for your project's unique demands.

Contact our engineering team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why are PTFE lined butterfly valves considered cost-effective? Maximize ROI with Lower Lifetime Costs

- In which industries are PTFE lined ball valves commonly used? Master Corrosive & High-Purity Fluid Control

- How is virgin PTFE processed into sheets? A Guide to Purity, Performance, and Trade-offs

- What role do PTFE guide strips play in the aerospace industry? Ensure Safety and Reliability in Critical Systems

- What engineering applications does PTFE have? Essential for Corrosion, Friction, and Insulation

- What are the disadvantages of PTFE processing machines? High Costs, Material Weaknesses, and Production Challenges

- What material is replacing carbon in seals and piston rings, and why? PTFE's Superior Durability & Lifespan

- What are some common applications of PTFE balls? Essential Uses in Chemical & Low-Friction Systems