Choosing the right ball valve seat material is a critical decision that directly determines the valve's ability to seal effectively and operate safely. The seat is the component responsible for creating a leak-proof seal against the ball, and an incorrect material choice can lead to valve failure, compromising both the process and the environment in industries from petrochemicals to pharmaceuticals.

The core function of a valve is to control flow, and this hinges entirely on the integrity of the seal. The valve seat material must be selected by rigorously matching its chemical, thermal, and mechanical properties to the specific demands of the application to prevent leakage and ensure reliable performance.

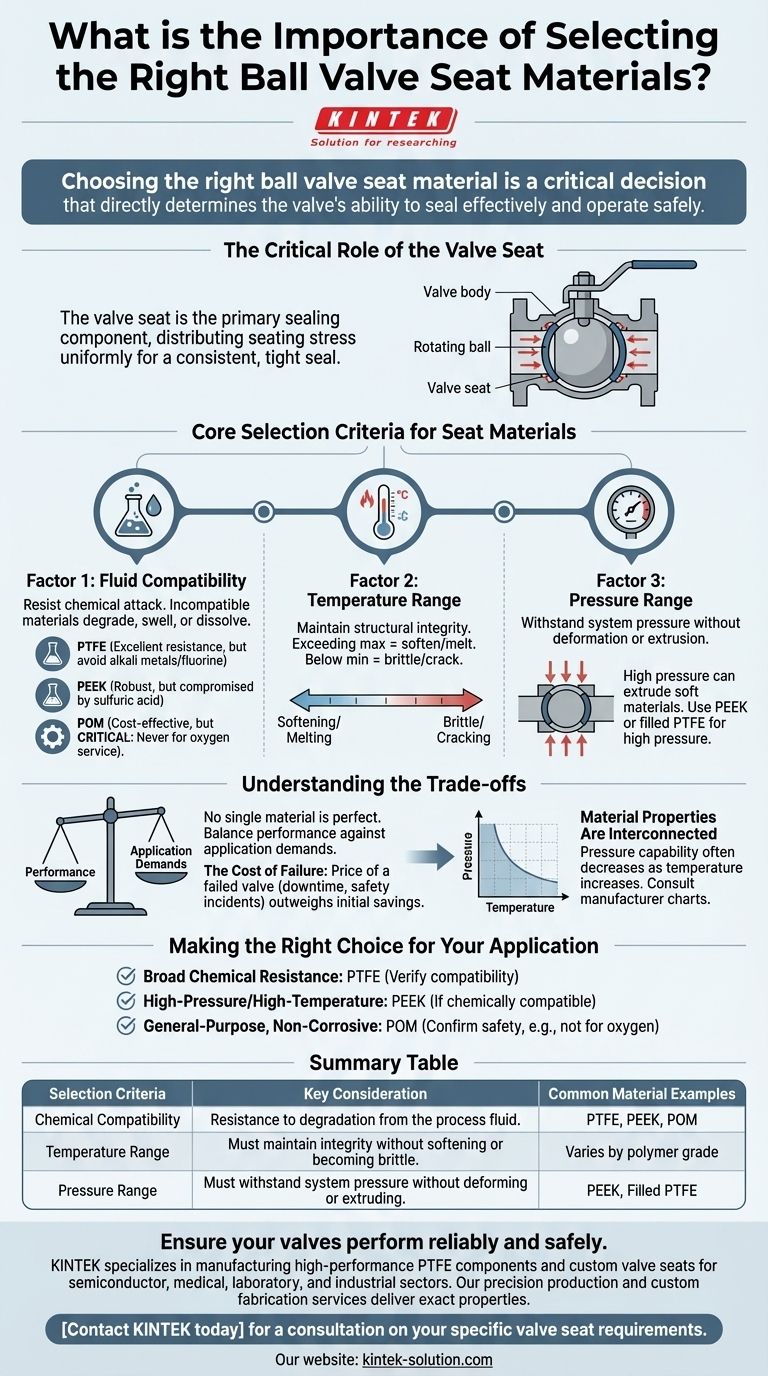

The Critical Role of the Valve Seat

A ball valve's performance is only as good as its weakest component, and the seat is often the most critical element for sealing. Understanding its function is key to making an informed material choice.

The Primary Sealing Component

The valve seat is a ring that sits between the valve body and the rotating ball. When the valve is in the closed position, the ball presses firmly against the seat, creating the primary seal that stops the flow of the fluid.

Distributing Seating Stress

A well-designed seat also distributes the pressure from the ball uniformly. This ensures a consistent, tight seal across the entire surface and prevents localized stress that could damage the seat or ball over time.

Core Selection Criteria for Seat Materials

To ensure a material can operate effectively, you must evaluate it against three primary factors: the fluid it will handle, the temperature it will endure, and the pressure it must contain.

Factor 1: Fluid Compatibility

This is the material's ability to resist chemical attack from the process fluid. An incompatible material can degrade, swell, or dissolve, leading to immediate seal failure.

For example, PTFE (Polytetrafluoroethylene) offers excellent resistance to a wide range of chemicals. However, it can be attacked by molten alkali metals or fluorine.

Similarly, PEEK (Polyetheretherketone) is highly robust but can be compromised by contact with concentrated sulfuric acid. A material like POM (Polyoxymethylene/Acetal) is widely used but is critically unsuitable for oxygen service due to the risk of a dangerous reaction.

Factor 2: Temperature Range

Every material has a specific temperature range within which it maintains its structural integrity and sealing properties.

Exceeding the maximum temperature can cause the seat to soften, deform, or even melt, resulting in a complete loss of the seal. Operating below its minimum temperature can cause the material to become brittle and crack.

Factor 3: Pressure Range

The seat material must be strong enough to withstand the system's operating pressure without being deformed or extruded out of its retaining groove.

High pressure can physically push a softer material like standard PTFE out of place. For these applications, a stronger material like PEEK or a filled grade of PTFE is required to maintain the seal's position and integrity.

Understanding the Trade-offs

No single material is perfect for every situation. The choice always involves balancing performance characteristics against the demands of the application.

The Cost of Failure

Choosing a material based on cost alone without considering the operational demands is a common mistake. The price of a failed valve—in terms of downtime, lost product, and potential safety incidents—far outweighs the initial savings on a less suitable seat material.

Material Properties Are Interconnected

It is crucial to remember that temperature and pressure capabilities are often linked. A material's ability to withstand pressure typically decreases as its operating temperature increases. Always consult the manufacturer's pressure-temperature charts for the specific material you are considering.

Making the Right Choice for Your Application

Your selection process should be a systematic evaluation of your operating conditions against the known properties of available materials.

- If your primary focus is broad chemical resistance in moderate conditions: PTFE is often the default choice, but you must verify its compatibility with your specific fluid and operating parameters.

- If your primary focus is high-pressure or high-temperature service: A high-performance polymer like PEEK is a superior candidate, provided it is chemically compatible with the media.

- If your primary focus is a general-purpose, non-corrosive application: Materials like POM can be a cost-effective solution, but it is absolutely critical to confirm they are safe for the specific fluid (e.g., never for oxygen).

Ultimately, a meticulous evaluation of your system's demands is the foundation for selecting a valve seat that ensures a reliable and safe operation.

Summary Table:

| Selection Criteria | Key Consideration | Common Material Examples |

|---|---|---|

| Chemical Compatibility | Resistance to degradation from the process fluid. | PTFE, PEEK, POM |

| Temperature Range | Must maintain integrity without softening or becoming brittle. | Varies by polymer grade |

| Pressure Range | Must withstand system pressure without deforming or extruding. | PEEK, Filled PTFE |

Ensure your valves perform reliably and safely. The right seat material is critical for preventing leaks and costly downtime. KINTEK specializes in manufacturing high-performance PTFE components, including custom valve seats, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—deliver the exact chemical and mechanical properties your application demands.

Contact KINTEK today for a consultation on your specific valve seat requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications