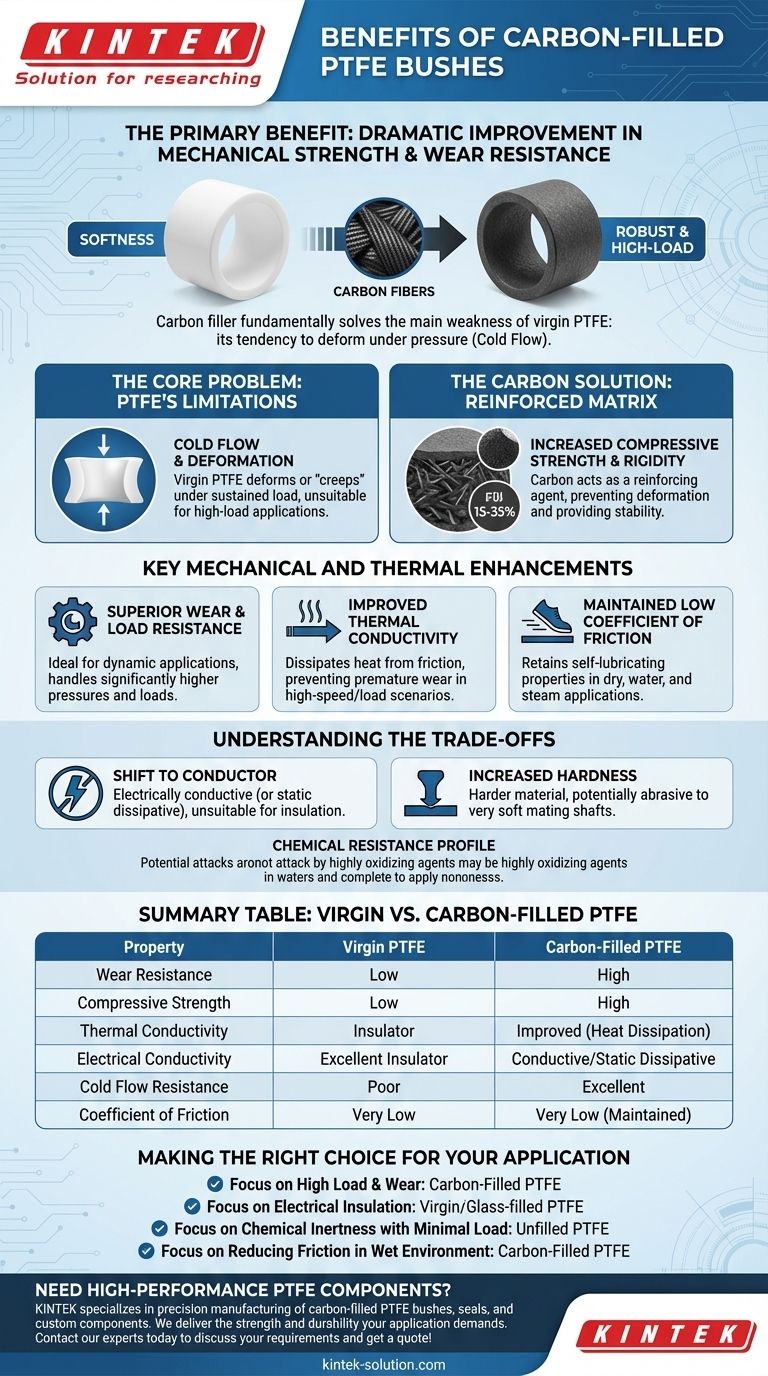

The primary benefit of carbon-filled PTFE bushes is a dramatic improvement in mechanical strength and wear resistance over the unfilled material. Adding carbon fiber or powder transforms standard PTFE, known for its softness, into a robust engineering component capable of handling moderate to high loads while retaining its signature low friction and chemical inertness.

Carbon filler fundamentally solves the main weakness of virgin PTFE: its tendency to deform under pressure, a phenomenon known as "cold flow." This reinforcement creates a high-strength, wear-resistant material ideal for demanding mechanical applications that require self-lubrication.

The Core Problem Carbon Solves: Overcoming PTFE's Limitations

Polytetrafluoroethylene (PTFE) is an exceptional material, but its pure form has significant structural weaknesses. Adding a carbon filler is a direct solution to these challenges.

The Challenge of "Cold Flow" in Virgin PTFE

Virgin PTFE is a relatively soft material. When subjected to a sustained load, especially at elevated temperatures, it can permanently deform or "creep."

This characteristic, often called cold flow, makes unfilled PTFE unsuitable for high-load bearings or structural components where dimensional stability is critical.

How Carbon Filler Creates a Stronger Matrix

Carbon, typically in fiber or powder form with fill percentages ranging from 15% to 35%, acts as a reinforcing agent within the PTFE matrix.

This composite structure dramatically increases the material's compressive strength and rigidity. It effectively prevents the PTFE from deforming under load, providing the stability needed for mechanical applications.

Key Mechanical and Thermal Enhancements

The addition of carbon provides a specific set of performance boosts that make it a superior choice for many applications.

Superior Wear and Load Resistance

Carbon-filled PTFE exhibits vastly improved wear resistance against mating surfaces. This makes it ideal for dynamic applications like seals, piston rings, and bushings that experience continuous movement.

The increased stiffness also allows the material to handle significantly higher pressures and loads than its unfilled counterpart.

Improved Thermal Conductivity

A critical benefit of carbon is its ability to improve thermal conductivity. Pure PTFE is a thermal insulator, meaning it traps heat generated by friction.

Carbon helps dissipate this heat away from the contact surface, preventing premature wear and failure in high-speed or high-load scenarios.

Maintained Low Coefficient of Friction

Crucially, carbon-filled PTFE maintains an exceptionally low coefficient of friction. This means it retains the self-lubricating properties that make PTFE so valuable.

This characteristic is stable across dry, water, and even steam applications, ensuring smooth operation without external lubricants.

Understanding the Trade-offs

While the benefits are significant, introducing carbon filler alters some of PTFE's fundamental properties, which must be considered.

The Shift from Insulator to Conductor

Virgin PTFE is an excellent electrical insulator. The addition of carbon, which is conductive, changes this property entirely.

Carbon-filled PTFE becomes electrically conductive (or at least statically dissipative). This makes it completely unsuitable for applications requiring electrical insulation.

Increased Hardness

The resulting material is harder than virgin PTFE. While this contributes to wear resistance, it can be slightly more abrasive to very soft mating shafts, such as those made from aluminum or plastic.

Chemical Resistance Profile

While general chemical resistance remains excellent, the carbon filler may be attacked by highly oxidizing agents that would not affect pure PTFE. This is only a concern in the most aggressive chemical environments.

Making the Right Choice for Your Application

Selecting the correct material grade depends entirely on your primary engineering goal.

- If your primary focus is high load and wear resistance: Carbon-filled PTFE is the superior choice for bearings, seals, and bushings under mechanical stress.

- If your primary focus is electrical insulation: You must use virgin PTFE or a PTFE variant with a non-conductive filler, such as glass.

- If your primary focus is ultimate chemical inertness with minimal load: Unfilled PTFE may be sufficient and is often more cost-effective.

- If your primary focus is reducing friction in a wet environment: Carbon-filled PTFE excels, as it does not absorb water and maintains its low-friction properties.

Ultimately, choosing carbon-filled PTFE is a deliberate engineering decision to gain mechanical resilience and thermal stability where it matters most.

Summary Table:

| Property | Virgin PTFE | Carbon-Filled PTFE |

|---|---|---|

| Wear Resistance | Low | High |

| Compressive Strength | Low | High |

| Thermal Conductivity | Insulator | Improved (Heat Dissipation) |

| Electrical Conductivity | Excellent Insulator | Conductive/Static Dissipative |

| Cold Flow Resistance | Poor | Excellent |

| Coefficient of Friction | Very Low | Very Low (Maintained) |

Need high-performance PTFE components that can handle the load?

KINTEK specializes in precision manufacturing of carbon-filled PTFE bushes, seals, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We deliver the strength and durability your application demands, from prototypes to high-volume production.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech