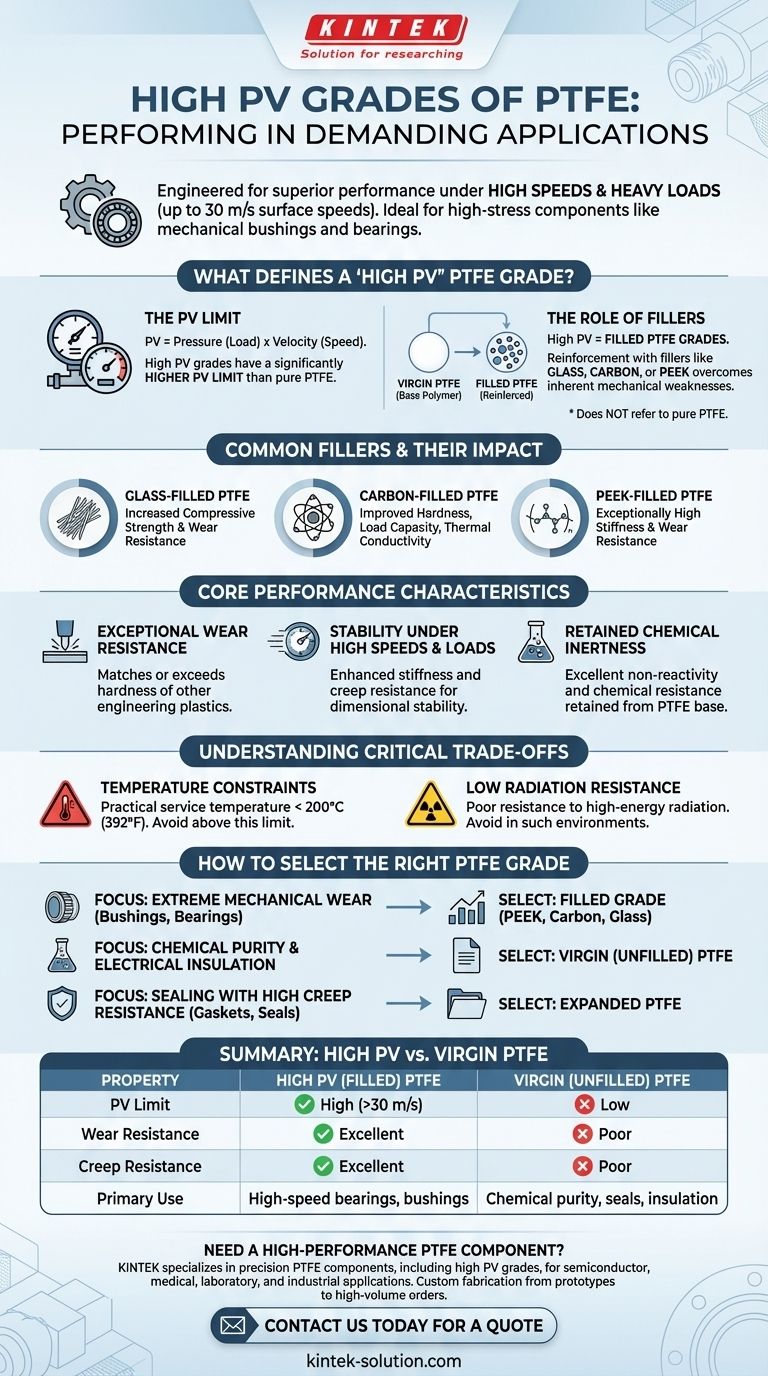

In demanding applications, high PV grades of PTFE excel by delivering superior performance under high speeds and heavy loads. These specialized grades are specifically engineered to operate at surface speeds up to 30 m/s, making them ideal for high-stress components like mechanical bushings and bearings where standard plastics would quickly fail.

The term "high PV" does not refer to pure PTFE, but rather to filled PTFE grades. The exceptional performance in high-pressure, high-velocity environments is achieved by adding reinforcement fillers like glass, carbon, or PEEK to overcome the inherent mechanical weaknesses of virgin PTFE.

What Defines a "High PV" PTFE Grade?

To understand how these materials perform, we must first clarify what makes them distinct from standard PTFE. The key is the intentional modification of the base polymer.

The Pressure-Velocity (PV) Limit

The PV limit is a critical engineering metric for bearing materials. It represents the maximum combination of pressure (load) and velocity (speed) a material can withstand before failing due to frictional heat and mechanical wear.

High PV grades are formulated to have a significantly higher PV limit than pure PTFE, allowing them to function reliably in more aggressive mechanical systems.

The Role of Fillers: The Key to Performance

Virgin PTFE is known for its low friction and chemical inertness but suffers from poor mechanical properties like low strength, high wear, and a tendency to creep (deform under sustained load).

Fillers are added to the PTFE matrix to counteract these weaknesses. This reinforcement is the defining characteristic of a high PV grade.

Common Fillers and Their Impact

Different fillers impart specific properties to the final material:

- Glass-Filled PTFE: Incorporates glass fibers to dramatically increase compressive strength and wear resistance.

- Carbon-Filled PTFE: Adds carbon to improve hardness, load-bearing capacity, and thermal conductivity, which helps dissipate frictional heat.

- PEEK-Filled PTFE: Blends PTFE with PEEK (Polyetheretherketone) to create a premium composite with exceptionally high stiffness and wear resistance for the most demanding environments.

Core Performance Characteristics

By leveraging these fillers, high PV grades of PTFE deliver a unique combination of properties tailored for severe service applications.

Exceptional Wear Resistance

Filled PTFE grades can be customized to match or even exceed the hardness of other engineering plastics. This makes them highly resistant to abrasive wear in high-stress contact applications.

Stability Under High Speeds and Loads

The enhanced stiffness and creep resistance from fillers ensure that components maintain their dimensional stability under high mechanical stress. This is what makes them suitable for high-speed bushings and bearings.

Retained Chemical Inertness

While fillers enhance mechanical properties, the material retains the PTFE base's excellent non-reactivity and chemical resistance. This makes it a valuable choice for moving parts in chemically aggressive environments.

Understanding the Critical Trade-offs and Limitations

No material is perfect. Acknowledging the trade-offs of PTFE is essential for proper material selection and avoiding application failure.

The Weakness of Unfilled (Virgin) PTFE

It is critical to remember that unfilled PTFE is unsuitable for high PV applications. Its high wear rate and low resistance to creep and abrasion would lead to rapid failure.

Temperature Constraints

While PTFE has a high melting point, its practical service temperature is lower. Above 200°C (392°F), all grades of PTFE begin to experience significant thermal expansion and creep, which can cause permanent deformation.

Low Radiation Resistance

PTFE has poor resistance to high-energy radiation, which can break down its molecular structure. It should be avoided in applications with significant radiation exposure.

Non-Melt Processability

As a thermoset, PTFE cannot be melt-processed like common thermoplastics. This limits manufacturing to methods like compression molding and machining, which can impact component design and cost.

How to Select the Right PTFE Grade

Choosing the correct material requires a clear understanding of your primary engineering goal.

- If your primary focus is extreme mechanical wear (bushings, bearings): Select a filled grade like PEEK-filled, carbon-filled, or glass-filled PTFE for maximum strength and durability.

- If your primary focus is ultimate chemical purity and electrical insulation: Virgin (unfilled) PTFE is the superior choice, as fillers are not required and could be a source of contamination.

- If your primary focus is sealing with high creep resistance (gaskets, seals): Expanded PTFE offers excellent stability and resistance to surface pressure, making it ideal for these static applications.

Ultimately, leveraging a high PV grade of PTFE allows you to harness the material's low friction and chemical stability in applications far beyond the reach of its pure form.

Summary Table:

| Property | High PV (Filled) PTFE | Virgin (Unfilled) PTFE |

|---|---|---|

| PV Limit | High (>30 m/s) | Low |

| Wear Resistance | Excellent | Poor |

| Creep Resistance | Excellent | Poor |

| Primary Use | High-speed bearings, bushings | Chemical purity, seals, insulation |

Need a high-performance PTFE component for a demanding application?

KINTEK specializes in manufacturing precision PTFE components, including high PV grades filled with glass, carbon, or PEEK for superior performance in semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the common issues hindering the adoption of PTFE wear plates? Overcome These 4 Key Barriers

- What makes PTFE seals suitable for food and pharmaceutical applications? Ensure Purity and Compliance

- What pressure conditions should be maintained for PTFE lined butterfly valves? Avoid Costly Valve Failure

- How does heat exposure affect PTFE seals? Mastering Thermal Expansion for Superior Sealing

- What are the advantages of PTFE O-rings compared to elastomeric O-rings? Superior Performance in Extreme Conditions

- How can the disadvantages of PTFE processing machines be mitigated? Manage Trade-offs for Optimal Performance

- What chemical resistance do ePTFE gaskets have? Superior Sealing for Aggressive Chemicals

- How are PTFE rods utilized in electronic and electrical applications? Unlock Superior Performance & Reliability