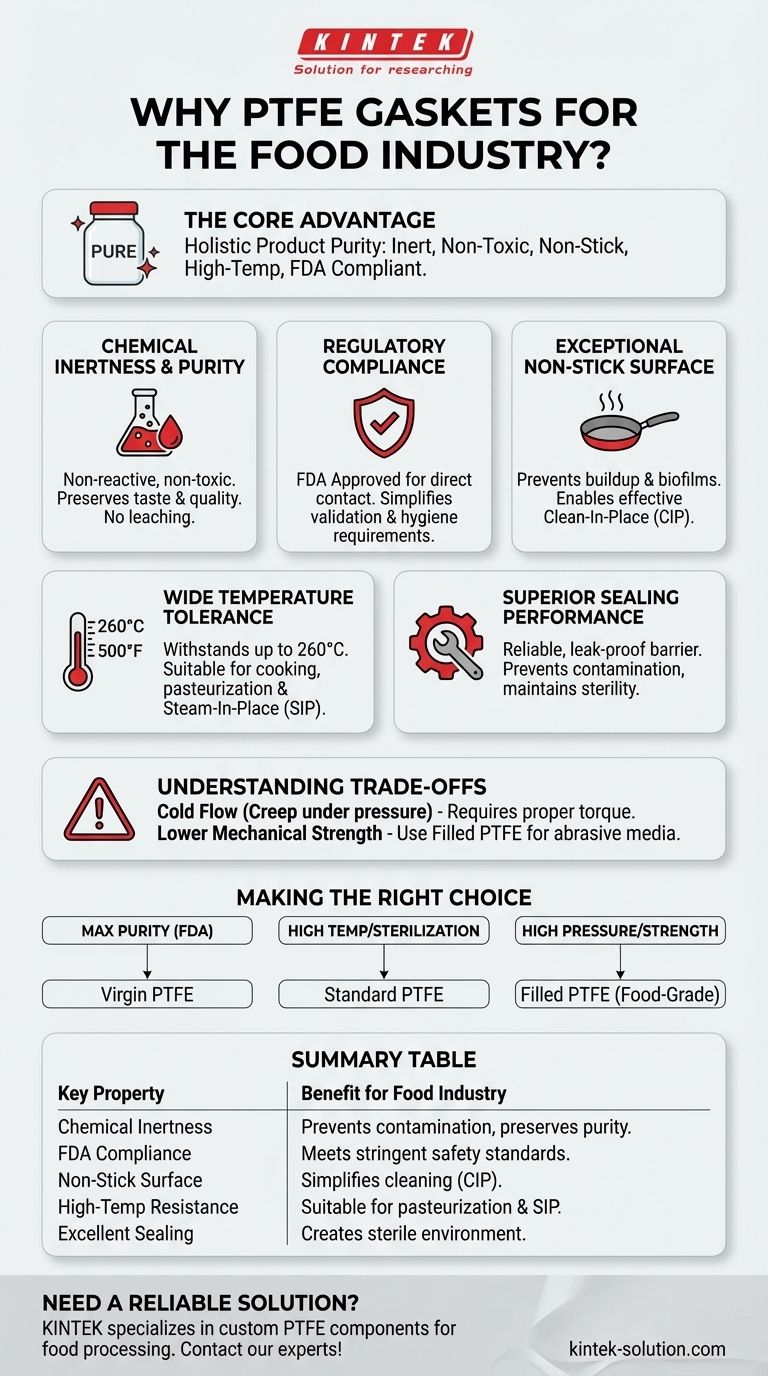

At its core, the suitability of Polytetrafluoroethylene (PTFE) gaskets for the food industry stems from a unique combination of properties. They are chemically inert, non-toxic, possess a non-stick surface, and tolerate high temperatures, all while meeting the stringent regulatory standards required for direct food contact.

The true value of PTFE in food processing is not just one of its features, but its holistic ability to guarantee product purity. It creates a reliable seal that does not react with, adhere to, or contaminate the food product in any way.

The Core Properties Driving Food Safety

Understanding why PTFE is a default choice requires examining the specific material characteristics that directly address the primary concerns of the food and beverage industry: hygiene, compliance, and operational reliability.

Chemical Inertness and Purity

PTFE is chemically non-reactive, meaning it will not react with or leach into the food products it contacts. This inert nature is fundamental to preserving the taste, quality, and safety of the final product.

Because the material is non-toxic and does not adsorb media, it ensures that nothing from the gasket itself contaminates the process flow. This is critical in sensitive applications like dairy, beverage, and pharmaceutical manufacturing.

Regulatory Compliance

Crucially, PTFE meets rigorous standards set by regulatory bodies. It is widely approved by the FDA for materials that come into direct contact with food.

This compliance simplifies the validation process for equipment manufacturers and food producers, providing a clear path to meeting hygiene and safety requirements.

Exceptional Non-Stick Surface

The well-known non-stick properties of PTFE are highly beneficial in a sanitary environment. This characteristic prevents food materials and microbial biofilms from building up on the gasket surface.

This not only prevents a major source of contamination but also facilitates easier and more effective cleaning cycles, such as Clean-In-Place (CIP) procedures.

Wide Temperature Tolerance

PTFE gaskets can withstand a broad range of temperatures, often up to 260°C (500°F). This makes them suitable for processes involving cooking, pasteurization, or hot filling.

This thermal stability also ensures they remain effective during high-temperature sterilization processes, like Steam-In-Place (SIP), without degrading or compromising the seal.

Superior Sealing Performance

A primary function of any gasket is to prevent leaks. PTFE provides a highly effective and tight seal in processing machinery, which is essential for maintaining both hygiene and operational safety.

By preventing fluid leakage, these gaskets eliminate potential points of external contamination and ensure the process remains contained and sterile.

Understanding the Trade-offs

While PTFE is an exceptional material, no single solution is perfect for every application. Acknowledging its limitations is key to using it effectively and avoiding potential failures.

Susceptibility to Cold Flow

The most significant consideration for PTFE is its tendency for creep, or "cold flow." Under sustained pressure and temperature, the material can slowly deform, which may lead to a loss of sealing pressure over time.

This characteristic requires careful attention during installation, particularly regarding bolt torque specifications, to ensure a long-lasting and reliable seal.

Lower Mechanical Strength

Compared to metallic or some elastomeric gaskets, pure PTFE is a relatively soft material with lower abrasion resistance. It may not be the ideal choice for applications involving highly abrasive media.

In such cases, filled or modified PTFE (which includes additives like glass or stainless steel) can be used to improve mechanical strength, though it's critical to ensure the filler material is also food-grade.

Making the Right Choice for Your Application

Selecting the right gasket material depends entirely on the specific demands of your process. PTFE offers a powerful solution when purity and compliance are paramount.

- If your primary focus is maximum product purity and FDA compliance: Virgin PTFE is the definitive choice due to its inert and non-toxic nature.

- If your primary focus is high-temperature processing or sterilization: PTFE's excellent thermal stability ensures seal integrity during SIP and hot-fill operations.

- If your primary focus is sealing in high-pressure or structurally demanding systems: Consider a filled PTFE variant to mitigate creep, ensuring the filler meets all necessary food-contact regulations.

Ultimately, PTFE's unique properties make it an indispensable tool for ensuring safety and integrity in the modern food processing environment.

Summary Table:

| Key Property | Benefit for Food Industry |

|---|---|

| Chemical Inertness | Non-reactive, prevents contamination, preserves product taste and purity. |

| FDA Compliance | Meets stringent regulatory standards for direct food contact. |

| Non-Stick Surface | Prevents buildup of food residues and biofilms, simplifies cleaning (CIP). |

| High-Temperature Resistance | Withstands heat up to 260°C (500°F), suitable for pasteurization and SIP. |

| Excellent Sealing | Creates a reliable, leak-proof barrier to maintain a sterile process environment. |

Need a reliable, food-grade sealing solution?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and food processing industries. Our expertise ensures your equipment meets the highest standards of purity and regulatory compliance.

We offer custom fabrication from prototypes to high-volume orders, tailoring PTFE solutions to your exact application requirements.

Contact our experts today to discuss how our PTFE gaskets can enhance the safety and efficiency of your food processing operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What temperature range can PTFE rods withstand? From -200°C to +260°C for Extreme Versatility

- What factors should be considered when choosing between PTFE and non-PTFE laminates? Optimize Performance vs. Cost

- What operational advantages do PTFE slide bearings offer in construction projects? Achieve Maintenance-Free Structural Movement

- What customization options are available for PTFE rotary shaft seals? Tailor for High Performance

- Why are PTFE fasteners considered a key component in advanced medical devices? Unlock Superior Safety & Reliability

- What are machined PTFE parts made of? The Power of Pure Carbon and Fluorine

- How is PTFE utilized in the semiconductor industry? Essential for High-Purity and Yield

- What are the general safety precautions when cleaning Teflon residue? Protect Your Team and Equipment