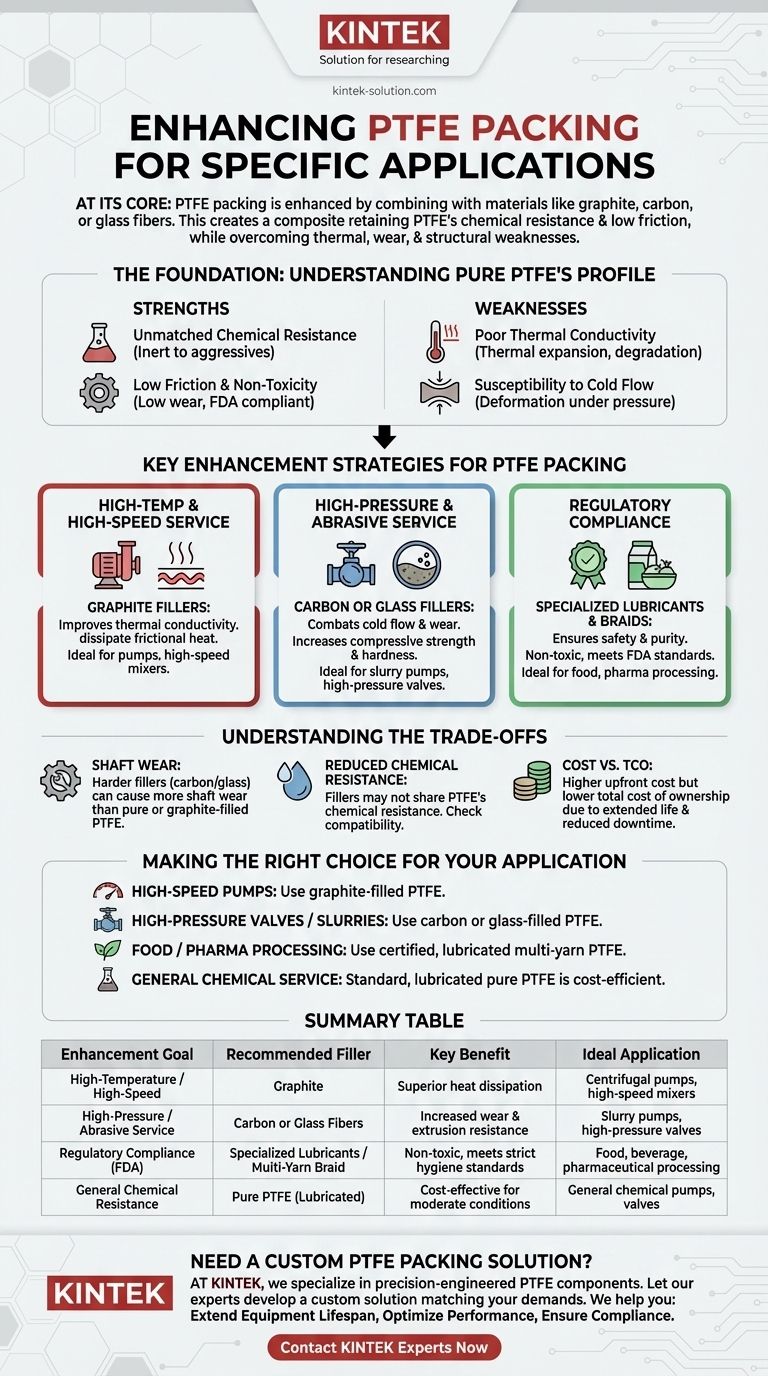

At its core, PTFE packing is enhanced for specific applications by combining it with other materials, such as graphite, carbon, or glass fibers. This process creates a composite material that retains PTFE's exceptional chemical resistance and low friction while systematically overcoming its inherent weaknesses in areas like thermal conductivity, wear resistance, and structural rigidity under pressure.

The key to optimizing PTFE packing is understanding that pure PTFE has limitations, particularly with heat dissipation and deformation under load. Enhancements are not arbitrary; they are targeted engineering solutions designed to compensate for these specific weaknesses, tailoring the packing for high-temperature, high-pressure, or abrasive service.

The Foundation: Understanding Pure PTFE's Profile

To appreciate the enhancements, we must first understand the strengths and weaknesses of pure Polytetrafluoroethylene (PTFE) as a packing material.

Strength: Unmatched Chemical Resistance

PTFE is virtually inert and resistant to the most aggressive chemicals, acids, and gases. This makes it a default choice for systems handling corrosive substances, strong oxidizers, and various industrial fluids.

Strength: Low Friction and Non-Toxicity

Its extremely low coefficient of friction minimizes wear on rotating shafts and reduces the energy needed to operate equipment. This property, combined with its non-toxic nature, allows for specialized formulations that meet strict FDA requirements for the food, beverage, and pharmaceutical industries.

Weakness: Poor Thermal Conductivity

PTFE is an excellent insulator, which is a disadvantage in dynamic sealing applications. Frictional heat generated at the shaft cannot dissipate effectively, leading to thermal expansion and potential degradation of the packing, especially at high speeds.

Weakness: Susceptibility to Cold Flow

Under sustained pressure, especially when temperatures rise, PTFE has a tendency to "cold flow" or deform. This can cause the packing to extrude out of the stuffing box, leading to a loss of sealing pressure and eventual failure.

Key Enhancement Strategies for PTFE Packing

Enhancements are designed to directly counter the weaknesses of pure PTFE, creating a high-performance composite tailored to a specific operational challenge.

For High-Temperature and High-Speed Service: Graphite Fillers

By impregnating the PTFE fibers with graphite, the packing's thermal conductivity is dramatically improved. The graphite acts as a pathway to draw frictional heat away from the shaft and dissipate it through the pump or valve housing.

This enhancement allows the packing to run at higher shaft speeds and handle higher temperatures without overheating, expanding, and failing. It directly solves PTFE's heat dissipation problem.

For High-Pressure and Abrasive Service: Carbon or Glass Fillers

To combat cold flow and wear, carbon or glass fibers are blended into the PTFE. These fillers create a reinforced matrix with significantly higher compressive strength and hardness.

This structure provides excellent resistance to deformation under high pressure, preventing extrusion. It also improves the packing's resilience when sealing abrasive slurries or in high-stress valve applications.

For Regulatory Compliance: Specialized Lubricants and Braids

For industries like food processing and pharmaceuticals, the enhancement focuses on safety and purity. Multi-yarn braiding techniques and the use of specific, FDA-compliant lubricants ensure the packing is non-toxic and non-reactive.

Here, the goal is not to boost physical performance but to meet critical regulatory standards for sterile and sensitive environments.

Understanding the Trade-offs

Selecting an enhanced packing involves balancing performance gains against potential downsides. No single solution is perfect for every scenario.

The Shaft Wear Dilemma

While carbon and glass-filled PTFE packings are highly durable, their increased hardness can cause more wear on the equipment's shaft compared to softer, pure PTFE. This is a critical trade-off: you may extend the life of the packing at the expense of a more costly component. Graphite-filled PTFE is generally less abrasive than carbon or glass-filled variants.

Potential for Reduced Chemical Resistance

While PTFE itself is nearly universally resistant, the filler material may not be. For example, glass-filled PTFE can be attacked by strong alkalis or hydrofluoric acid. You must ensure the chemical compatibility of both the PTFE and its enhancement material with your process media.

Cost vs. Total Cost of Ownership

Enhanced packings have a higher upfront cost than standard PTFE. However, their extended service life, reduced maintenance needs, and prevention of costly downtime often result in a lower total cost of ownership in demanding applications.

Making the Right Choice for Your Application

Your selection should be driven by the primary challenge you need to solve.

- If your primary focus is high-speed pumps: Use graphite-filled PTFE to effectively manage and dissipate frictional heat.

- If your primary focus is high-pressure valves or abrasive slurries: Use carbon or glass-filled PTFE for its superior wear and extrusion resistance.

- If your primary focus is food or pharmaceutical processing: Use a certified, lubricated multi-yarn PTFE packing that explicitly meets FDA standards.

- If your primary focus is general chemical service with moderate conditions: Standard, lubricated pure PTFE packing remains a highly effective and cost-efficient choice.

By matching the enhancement to the specific operational demand, you transform a simple seal into a precision-engineered solution for your equipment.

Summary Table:

| Enhancement Goal | Recommended Filler | Key Benefit | Ideal Application |

|---|---|---|---|

| High-Temperature / High-Speed | Graphite | Superior heat dissipation | Centrifugal pumps, high-speed mixers |

| High-Pressure / Abrasive Service | Carbon or Glass Fibers | Increased wear & extrusion resistance | Slurry pumps, high-pressure valves |

| Regulatory Compliance (FDA) | Specialized Lubricants / Multi-Yarn Braid | Non-toxic, meets strict hygiene standards | Food, beverage, pharmaceutical processing |

| General Chemical Resistance | Pure PTFE (Lubricated) | Cost-effective for moderate conditions | General chemical pumps, valves |

Need a Custom PTFE Packing Solution?

At KINTEK, we specialize in precision-engineered PTFE components. Whether you're battling extreme temperatures, high pressures, or abrasive media, our experts can develop a custom PTFE packing solution that perfectly matches your application's demands.

We help you:

- Extend Equipment Lifespan: Reduce downtime and maintenance costs with packing designed for durability.

- Optimize Performance: Get the right balance of chemical resistance, thermal management, and wear resistance.

- Ensure Compliance: Meet FDA and other regulatory standards for sensitive industries.

Contact us today for a consultation. Let's discuss your specific requirements and engineer a solution that enhances your operational efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What makes PTFE gaskets durable and long-lasting in ball valve applications? Uncover the Key Properties

- How does the long life and wear resistance of Teflon gland fillers reduce maintenance needs?

- What are the optimal load and speed conditions for PTFE performance? Master the PV Limit for Longevity

- What are the different grades of Teflon (PTFE) and their applications? A Guide to Material Selection

- What is the significance of biocompatibility in PTFE fasteners for medical devices? Ensure Patient Safety and Device Reliability

- What are the key properties of PTFE that make it suitable for structural bearings? Unlock Superior Load Support & Movement

- What are the common types of fillers used in PTFE compounds? Enhance Performance for Demanding Applications

- What are the differences between virgin PTFE and mechanical PTFE? Select the Right Grade for Your Application