The primary advantage of PTFE gaskets is their near-universal chemical inertness. This means they can reliably seal against an exceptionally broad range of aggressive substances without degrading. Polytetrafluoroethylene (PTFE) is resistant to most acids, alkalis, caustics, and solvents across the entire 0-14 pH spectrum, making it a default choice for the most demanding chemical processing applications.

The core value of PTFE's chemical resistance is not just its breadth, but its predictability. In environments where material failure could be catastrophic, PTFE provides a stable and non-reactive sealing solution, though it's critical to know its specific, albeit rare, vulnerabilities.

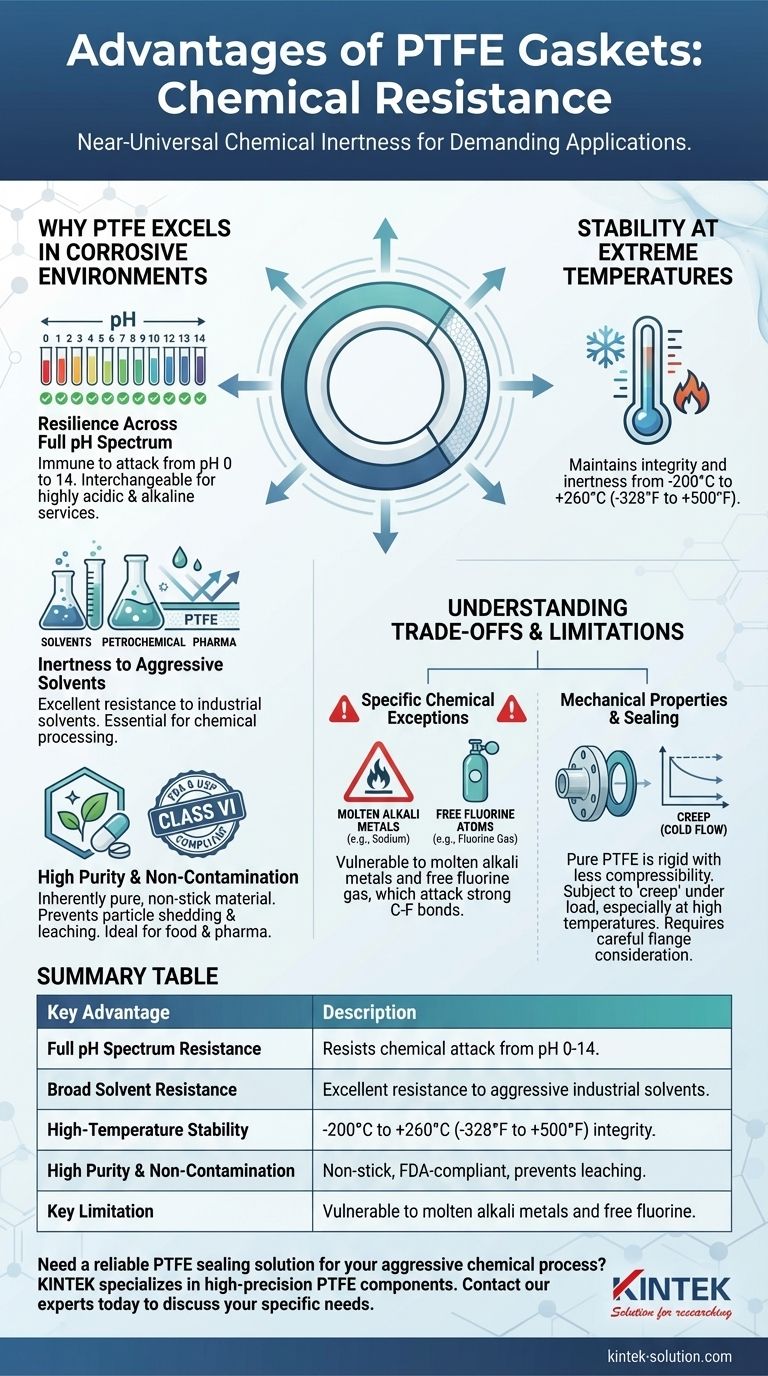

Why PTFE Excels in Corrosive Environments

The unique molecular structure of PTFE is what gives it such robust characteristics. This translates into several key performance advantages when handling aggressive media.

Resilience Across the Full pH Spectrum

PTFE is virtually immune to chemical attack from pH 0 to 14. This allows it to be used interchangeably for highly acidic and highly alkaline (caustic) services without concern for corrosion or degradation of the gasket material.

Inertness to Aggressive Solvents

Beyond acids and bases, PTFE gaskets demonstrate excellent resistance to a wide variety of industrial solvents. This makes them indispensable in petrochemical, pharmaceutical, and manufacturing industries where complex chemical compounds are common.

High Purity and Non-Contamination

PTFE is an inherently pure and stable material that meets FDA and USP Class VI standards. Its non-stick, anti-adhesion properties ensure that the gasket will not shed particles or leach contaminants into the process media, which is critical for food, beverage, and pharmaceutical applications.

Stability at Extreme Temperatures

A material's chemical resistance is only useful if it can withstand the system's operating temperature. PTFE maintains its integrity and chemical inertness in conditions ranging from -200°C to +260°C (-328°F to +500°F), ensuring a reliable seal during thermal cycling.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. While its chemical resistance is legendary, the decision to use PTFE requires an understanding of its specific limitations.

The Specific Chemical Exceptions

PTFE's near-universal resistance has two well-known exceptions: molten alkali metals (like sodium) and free fluorine atoms (such as fluorine gas). These highly reactive elements are among the few substances capable of attacking PTFE's strong carbon-fluorine bonds.

Mechanical Properties and Sealing

Compared to rubber or elastomeric gaskets, pure PTFE is a rigid material. It has less compressibility and recovery, which can make it difficult to achieve a tight seal on irregular or damaged flange surfaces or in applications with low bolt loads.

Tendency for Creep (Cold Flow)

Under sustained compressive load, especially at elevated temperatures, PTFE can be subject to "creep" or "cold flow." This is a slow deformation of the material that can lead to a loss of bolt torque and potentially compromise the long-term integrity of the seal. Composite or filled PTFE gaskets are often used to mitigate this effect.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's strengths to your operational demands.

- If your primary focus is handling a wide variety of aggressive chemicals: PTFE is an industry-standard choice due to its nearly universal inertness across the full pH range.

- If your primary focus is high-purity or sanitary applications: The non-contaminating and FDA-compliant nature of PTFE makes it an ideal sealing material.

- If your application involves sealing highly reactive molten alkali metals or fluorine gas: You must seek a specialized alternative, as these are the specific chemicals that will degrade PTFE.

- If your system involves low bolt loads or imperfect flanges: Consider a PTFE envelope gasket, which combines a chemically resistant PTFE shell with a more compressible core.

Ultimately, selecting a PTFE gasket is a decision for unparalleled chemical resilience in applications where material failure is not an option.

Summary Table:

| Key Advantage | Description |

|---|---|

| Full pH Spectrum Resistance | Resists chemical attack from pH 0 to 14, handling highly acidic and alkaline media. |

| Broad Solvent Resistance | Excellent resistance to a wide variety of aggressive industrial solvents. |

| High-Temperature Stability | Maintains integrity and inertness from -200°C to +260°C (-328°F to +500°F). |

| High Purity & Non-Contamination | Non-stick, FDA-compliant material that prevents particle shedding and leaching. |

| Key Limitation | Vulnerable to molten alkali metals and free fluorine gas. |

Need a reliable PTFE sealing solution for your aggressive chemical process?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom gaskets, seals, and liners. Our expertise ensures you get a sealing solution that delivers the unmatched chemical resistance you require for your semiconductor, medical, laboratory, or industrial application.

Contact our experts today to discuss your specific needs, from prototype to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications