When selecting Teflon (PTFE) for CNC machining, the most important considerations are its unique material properties and the specialized machining techniques they demand. You must account for its inherent softness, high thermal expansion, and tendency to form burrs by choosing the correct tooling, managing heat with coolant, and planning for post-processing from the outset.

Success with Teflon machining isn't about forcing it to act like metal; it's about adapting your process to respect its unique character. The key is to manage its thermal instability and softness with sharp tools, abundant coolant, and a pre-planned finishing strategy.

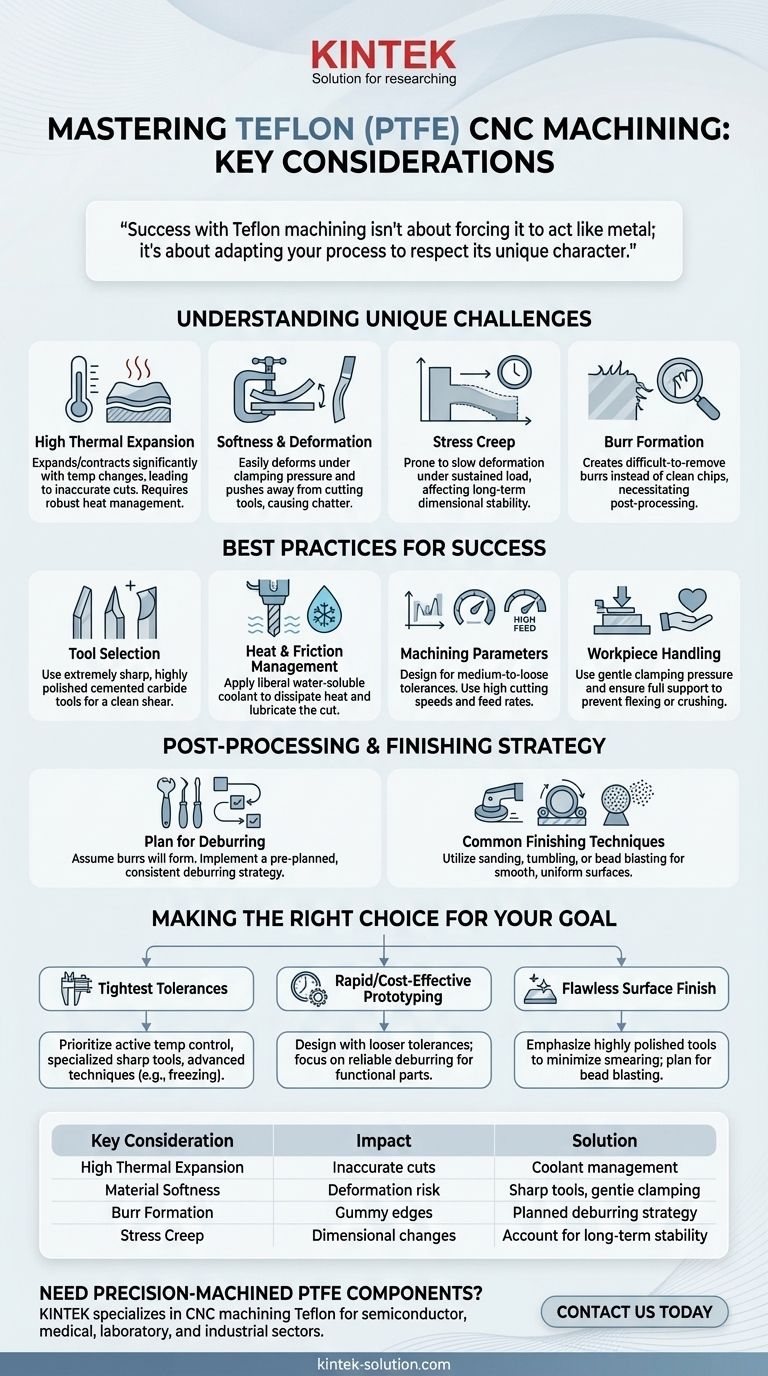

Understanding Teflon's Unique Machining Challenges

Teflon's desirable properties—chemical inertness and low friction—are directly linked to the characteristics that make it difficult to machine. Understanding these challenges is the first step toward a successful outcome.

High Thermal Expansion

Teflon has a high coefficient of thermal expansion. This means it expands and contracts significantly with temperature changes.

The heat generated during CNC machining can cause the material to swell, leading to inaccurate cuts. When the part cools, it will shrink to a different dimension than what was intended.

Softness and Deformation

Teflon is an exceptionally soft and flexible material. This creates two primary problems during machining.

First, it can easily deform under clamping pressure in the CNC machine, leading to dimensional inaccuracies. Second, the cutting tool can push the material away rather than shearing it cleanly, resulting in tool chatter and a poor surface finish.

Stress Creep

This material is prone to stress creep, which is the tendency to slowly deform over time when under a sustained load.

Even if a part meets tolerance immediately after machining, internal stresses or clamping forces can cause it to change shape hours or days later.

Burr Formation

Because of its softness, Teflon doesn't produce clean, brittle chips like a metal. Instead, it tends to create gummy, stringy burrs along the cut edges.

These burrs are often difficult to remove cleanly and require a specific post-processing strategy to achieve a finished part.

Best Practices for Successful Teflon Machining

Adapting your tools, parameters, and handling techniques is essential to overcome the challenges posed by Teflon. A methodical approach will prevent most common failures.

Tool Selection is Critical

Your cutting tools must be extremely sharp. Dull tools will rub against and smear the material rather than cutting it.

Use cemented carbide tools with highly polished surfaces and positive rake angles. These features help create a clean shearing action and improve chip clearance, preventing material buildup on the tool.

Managing Heat and Friction

Effective heat management is non-negotiable. Apply a liberal amount of water-soluble coolant directly at the cutting point.

The coolant serves two purposes: it dissipates heat to minimize thermal expansion and lubricates the cut to prevent the non-stick material from smearing.

Machining Parameters and Tolerances

Whenever possible, design parts with medium-to-loose tolerances. Achieving extremely tight tolerances with Teflon is difficult and expensive due to its instability.

Use high cutting speeds and feed rates. This allows the tool to cut the material quickly before significant heat can build up and cause deformation.

Workpiece Handling and Support

Use gentle clamping pressure to secure the workpiece without crushing or deforming it. Ensure the part is fully supported to prevent it from flexing away from the cutting tool.

For high-precision applications, a specialized technique involves freezing the material before machining. This temporarily increases its rigidity and reduces deformation.

The Necessity of Post-Processing and Finishing

For nearly all Teflon applications, machining is only the first step. A clean, functional part almost always requires a final finishing stage.

Plan for Deburring

Assume from the start that your machined part will have burrs. A pre-planned deburring strategy is a core part of the process.

Manual deburring with a sharp blade can work, but for better consistency, other methods are preferred.

Common Finishing Techniques

Techniques like sanding or tumbling can effectively remove burrs and smooth surfaces.

For a superior finish, bead blasting can be used to create a uniform, matte surface. In some cases, briefly re-freezing the part can make burrs more brittle and easier to snap off cleanly.

Making the Right Choice for Your Goal

Your specific objective will determine which machining considerations to prioritize.

- If your primary focus is achieving the tightest possible tolerances: Prioritize active temperature control, using sharp, specialized tools, and consider advanced techniques like freezing the material before machining.

- If your primary focus is rapid or cost-effective prototyping: Design parts with looser tolerances from the start and focus on a reliable deburring plan to achieve a functional, if not perfect, result.

- If your primary focus is a flawless, smooth surface finish: Emphasize using highly polished tools to minimize smearing and plan for post-processing methods like bead blasting.

Ultimately, mastering Teflon machining comes from anticipating the material's behavior and preparing for it at every stage of the process.

Summary Table:

| Key Consideration | Impact on Machining Process |

|---|---|

| High Thermal Expansion | Can cause inaccurate cuts; requires heat management with coolant. |

| Material Softness | Risk of deformation; demands sharp tools and gentle clamping. |

| Burr Formation | Creates gummy, stringy edges; necessitates a deburring strategy. |

| Stress Creep | Part may deform over time; affects long-term dimensional stability. |

Need precision-machined PTFE components?

At KINTEK, we specialize in CNC machining Teflon (PTFE) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing material softness, thermal expansion, and burr formation ensures your seals, liners, and custom labware meet exact specifications—from prototypes to high-volume production.

Contact us today to discuss your project and benefit from our precision production and custom fabrication capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs