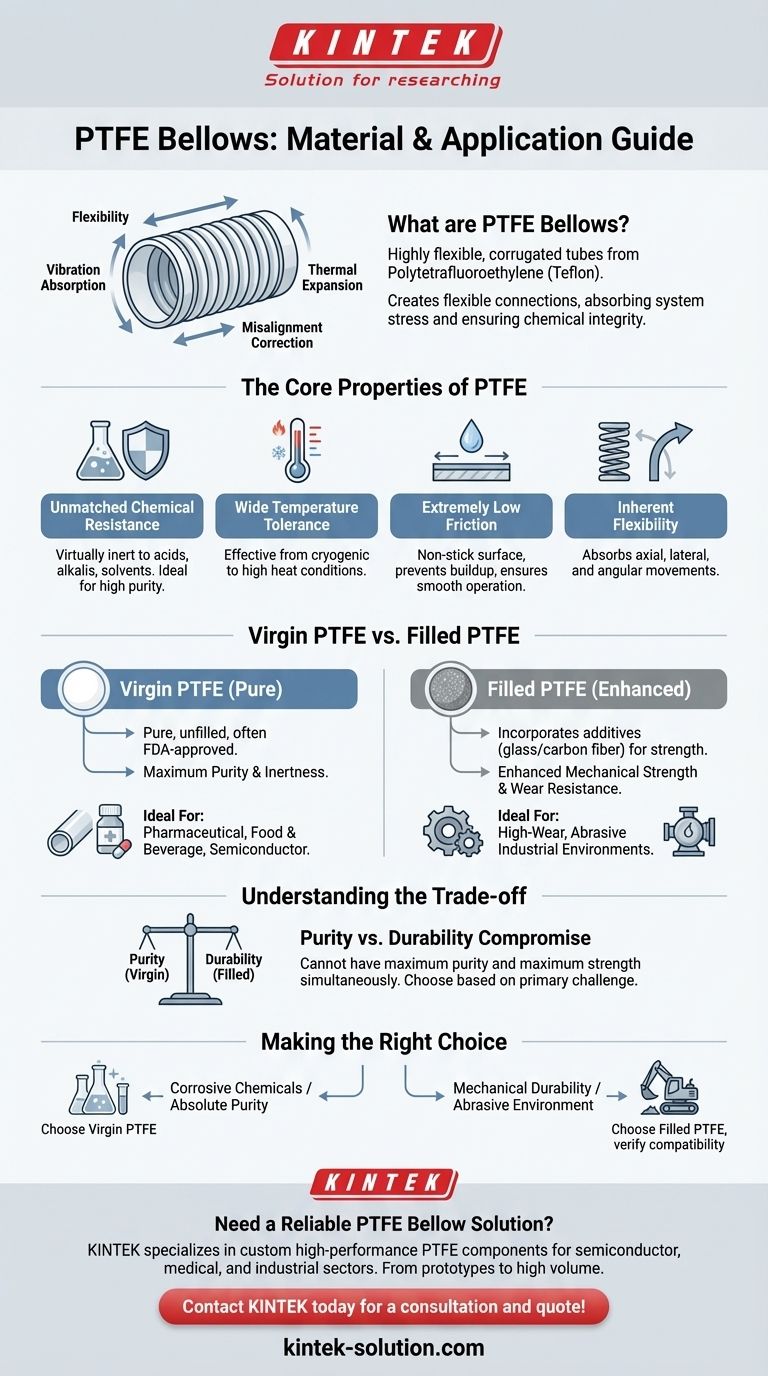

At their core, PTFE Bellows are highly flexible, corrugated tubes engineered from polytetrafluoroethylene, a high-performance fluoropolymer commonly known by the trade name Teflon. They are specifically designed to create a flexible connection within a piping system, absorbing vibration, thermal expansion, or misalignment, especially in environments where extreme chemical resistance is paramount.

The true value of a PTFE bellow is not just its flexibility, but its ability to provide that flexibility without compromising chemical integrity. The material's unique properties are what make this component a critical solution for highly demanding industrial applications.

The Core Properties of PTFE

To understand why PTFE is the material of choice for these components, we must look at its fundamental characteristics. These properties work in concert to deliver reliable performance in conditions where other materials would quickly fail.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. It provides exceptional corrosion resistance against strong acids, alkalis, and aggressive organic solvents.

This makes PTFE bellows indispensable in chemical processing, pharmaceutical, and semiconductor manufacturing where media purity and equipment longevity are critical.

Wide Temperature Tolerance

The material exhibits very good resistance to a wide range of temperatures. This allows PTFE bellows to function effectively in applications involving both high heat and cryogenic conditions.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This results in a non-stick surface with low surface tension.

For applications involving valves or the movement of viscous fluids, this property ensures smoother operation and prevents material buildup.

Inherent Flexibility

While the material itself is robust, the bellow design allows for significant axial, lateral, and angular movement. This engineering makes it possible to absorb system stresses without transferring them to more sensitive equipment.

Virgin PTFE vs. Filled PTFE

Not all PTFE is identical. The specific grade of the material is chosen based on the application's unique demands for purity or mechanical strength.

The Purity of Virgin PTFE

Virgin PTFE is pure, unfilled polytetrafluoroethylene. It is distinctly white and is often FDA-approved due to its high purity and biocompatibility.

This grade is the standard for food, beverage, and pharmaceutical applications where preventing contamination is a non-negotiable requirement.

The Strength of Filled PTFE

Filled PTFE incorporates additives like glass or carbon fibers into the base material. These fillers are designed to increase mechanical strength, durability, and wear resistance.

While stronger, filled PTFE does not maintain the same level of chemical purity as virgin PTFE and is used in more mechanically demanding industrial roles.

Understanding the Trade-offs

Selecting the right material requires acknowledging its inherent limitations. The decision between virgin and filled PTFE is a classic engineering compromise.

Mechanical Strength Considerations

While chemically superior, pure PTFE is a relatively soft material. It is not ideal for high-pressure applications or those involving significant abrasive wear without proper system design or reinforcement.

The Purity vs. Durability Compromise

The primary trade-off is clear: you can enhance mechanical properties or you can ensure maximum purity, but not both simultaneously.

Introducing fillers to boost strength inherently compromises the inertness and purity that defines virgin PTFE. You must choose which attribute is more critical for your system's success.

Making the Right Choice for Your Application

Your final selection should be guided by the primary challenge your system needs to solve.

- If your primary focus is handling highly corrosive chemicals or ensuring absolute product purity: Virgin PTFE is the only suitable choice, as its inertness is its greatest asset.

- If your primary focus is mechanical durability in an abrasive or high-wear environment: Filled PTFE offers enhanced strength, but you must carefully verify its chemical compatibility with your specific media.

Ultimately, choosing the correct bellow is about matching the unparalleled chemical performance of PTFE to the specific mechanical demands of your system.

Summary Table:

| Property | Virgin PTFE | Filled PTFE |

|---|---|---|

| Primary Advantage | Maximum Chemical Purity & Inertness | Enhanced Mechanical Strength & Wear Resistance |

| Ideal For | Pharmaceutical, Food & Beverage, Semiconductor | High-Wear, Abrasive Industrial Environments |

| Key Consideration | Soft material, not for high-pressure/abrasive use | Compromised chemical purity vs. virgin PTFE |

Need a reliable PTFE bellow solution for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bellows, seals, and liners. Whether your priority is absolute chemical purity with Virgin PTFE or enhanced durability with Filled PTFE, our expertise in precision production ensures a perfect match for your system's demands in the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders. Let us help you solve your toughest fluid handling challenges.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems