Fundamentally, PTFE bearing pads are specialized engineering components designed to manage movement and reduce stress in large-scale civil structures. Their most common applications are in the construction of large span and multi-span bridges, where they function as sliding surfaces to safely accommodate thermal expansion, beam rotation, and other significant structural displacements.

The true value of a PTFE bearing pad isn't just to support a load, but to provide a nearly frictionless surface that allows massive structures to safely expand, contract, and rotate. They essentially decouple a structure's superstructure from its substructure, preventing the buildup of destructive internal stresses.

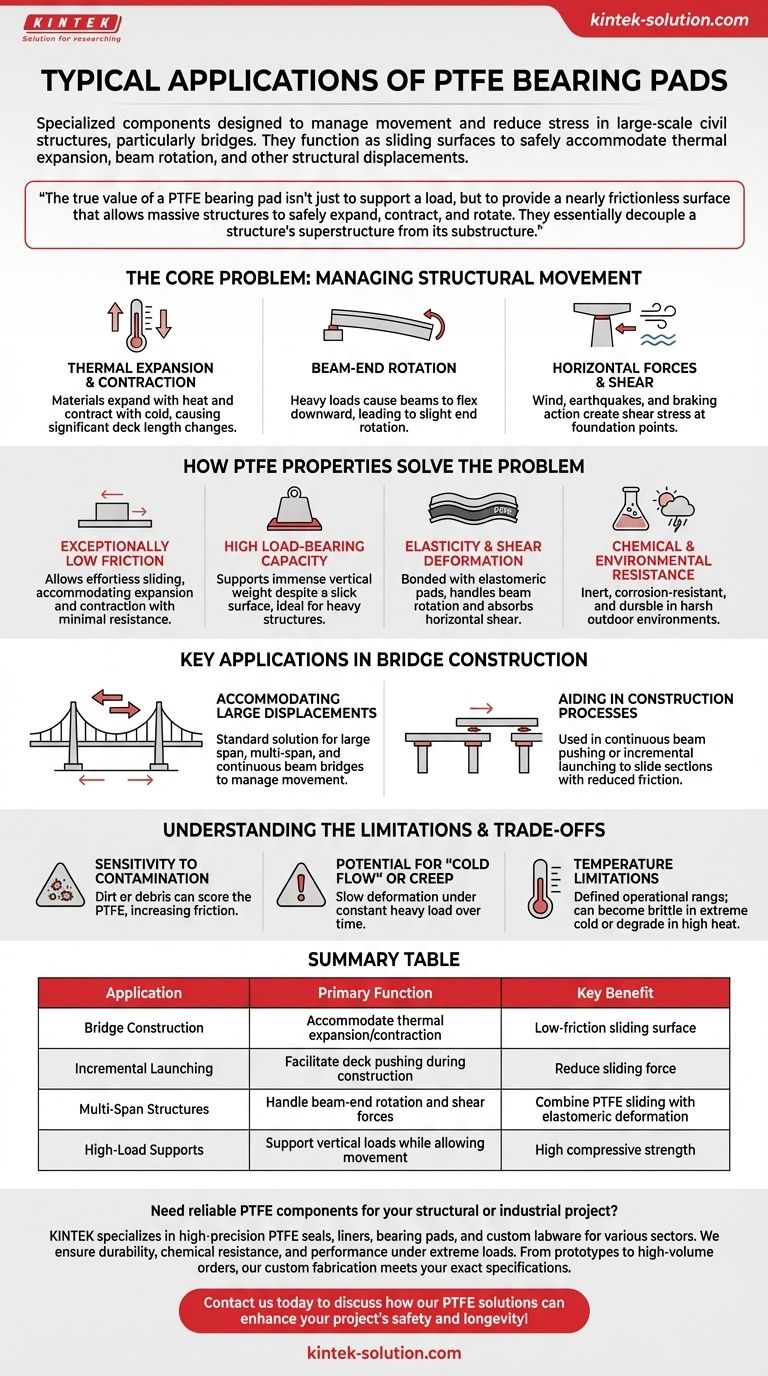

The Core Problem: Managing Structural Movement

Large structures like bridges are not static. They are constantly subjected to forces and environmental changes that cause them to move. A successful design must accommodate this movement, not resist it.

Thermal Expansion and Contraction

Materials expand when heated and contract when cooled. Over the length of a long bridge span, a significant temperature change can cause the deck to lengthen or shorten by several inches, creating immense force.

Beam-End Rotation

When a heavy load (like truck traffic) passes over a bridge beam, the beam flexes downward. This bending action causes the ends of the beam to rotate slightly, creating an angular displacement that must be accommodated by its support.

Horizontal Forces and Shear

Structures must also withstand horizontal forces from wind, water currents, earthquakes, or the braking action of vehicles. These forces create shear stress at the points where the structure meets its foundations.

How PTFE Properties Solve the Problem

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon®, possesses a unique combination of properties that make it an ideal material for structural bearings.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This allows the top plate of a bearing to slide effortlessly over the bottom plate, accommodating expansion and contraction with minimal resistance.

High Load-Bearing Capacity

Despite its slick surface, PTFE is incredibly strong under compression. This allows a relatively small bearing pad to support the immense vertical weight of a bridge deck or building floor.

Elasticity and Shear Deformation

When bonded to an elastomeric (rubber) pad, the bearing assembly can handle the slight rotation of beam ends. The rubber deforms elastically, while the PTFE layer continues to provide the sliding surface. This combination also absorbs and dampens horizontal shear forces.

Chemical and Environmental Resistance

PTFE is virtually inert and highly resistant to corrosion, weathering, and chemicals. This ensures exceptional durability and a long service life, even in the harsh outdoor environments where bridges are built.

Key Applications in Bridge Construction

While the principles apply to many large structures, PTFE bearing pads are most prevalent and critical in modern bridge engineering.

Accommodating Large Displacements

For large span, multi-span, and continuous beam bridges, managing movement is the primary design challenge. PTFE pads are the standard solution, providing a reliable sliding surface for the bridge deck.

Aiding in Construction Processes

PTFE pads are also used as temporary tools during the building phase. In methods like continuous beam pushing or incremental launching, entire sections of the bridge deck are slid into place over the piers using PTFE slide plates to reduce friction.

Understanding the Limitations and Trade-offs

While highly effective, PTFE bearings require careful design and installation to perform correctly. Understanding their limitations is key to ensuring structural integrity.

Sensitivity to Contamination

The low-friction surface of PTFE is its greatest asset, but it is also a vulnerability. Dirt, dust, gravel, or construction debris trapped between the sliding surfaces can score the PTFE, dramatically increasing friction and impairing movement.

Potential for "Cold Flow" or Creep

Like many polymers, PTFE can slowly deform over time when subjected to a constant, heavy load. This phenomenon, known as creep or "cold flow," must be accounted for in the engineering design to prevent long-term settlement issues.

Temperature Limitations

While durable, PTFE does have a defined operational temperature range. In extremely cold environments, it can become brittle, and in very high heat, its structural properties can degrade. The design must ensure the material stays within its specified limits.

Making the Right Choice for Your Project

Selecting the appropriate bearing type depends entirely on the specific movements and loads your structure needs to manage.

- If your primary focus is accommodating significant thermal or dynamic movement: PTFE pads are the default choice for large-span structures where low-friction sliding is essential.

- If your primary focus is supporting a static load with minimal expected movement: A simpler, non-sliding elastomeric bearing pad might be a more cost-effective solution.

- If your primary focus is facilitating a construction method like incremental launching: PTFE sliding plates are indispensable for reducing the immense forces required to move large structural segments into place.

By understanding these principles, you can confidently specify or evaluate the use of PTFE bearings as a critical component for ensuring structural integrity and longevity.

Summary Table:

| Application | Primary Function | Key Benefit |

|---|---|---|

| Bridge Construction | Accommodate thermal expansion/contraction | Low-friction sliding surface |

| Incremental Launching | Facilitate deck pushing during construction | Reduce sliding force |

| Multi-Span Structures | Handle beam-end rotation and shear forces | Combine PTFE sliding with elastomeric deformation |

| High-Load Supports | Support vertical loads while allowing movement | High compressive strength |

Need reliable PTFE components for your structural or industrial project? KINTEK specializes in manufacturing high-precision PTFE seals, liners, bearing pads, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We ensure durability, chemical resistance, and performance under extreme loads. From prototypes to high-volume orders, our custom fabrication meets your exact specifications. Contact us today to discuss how our PTFE solutions can enhance your project's safety and longevity!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application