The primary advantages of Teflon washers over nylon and other plastics are their exceptionally low friction, superior resistance to chemicals and water, and stability across a wide range of temperatures. These properties make Teflon (PTFE) the ideal choice for applications involving moving parts, harsh chemical environments, or exposure to moisture.

The decision between Teflon and nylon is not about which is universally "better," but about matching the material to the environment. Teflon excels where slipperiness, chemical inertness, and moisture immunity are critical, while nylon is often used for different mechanical or electrical purposes.

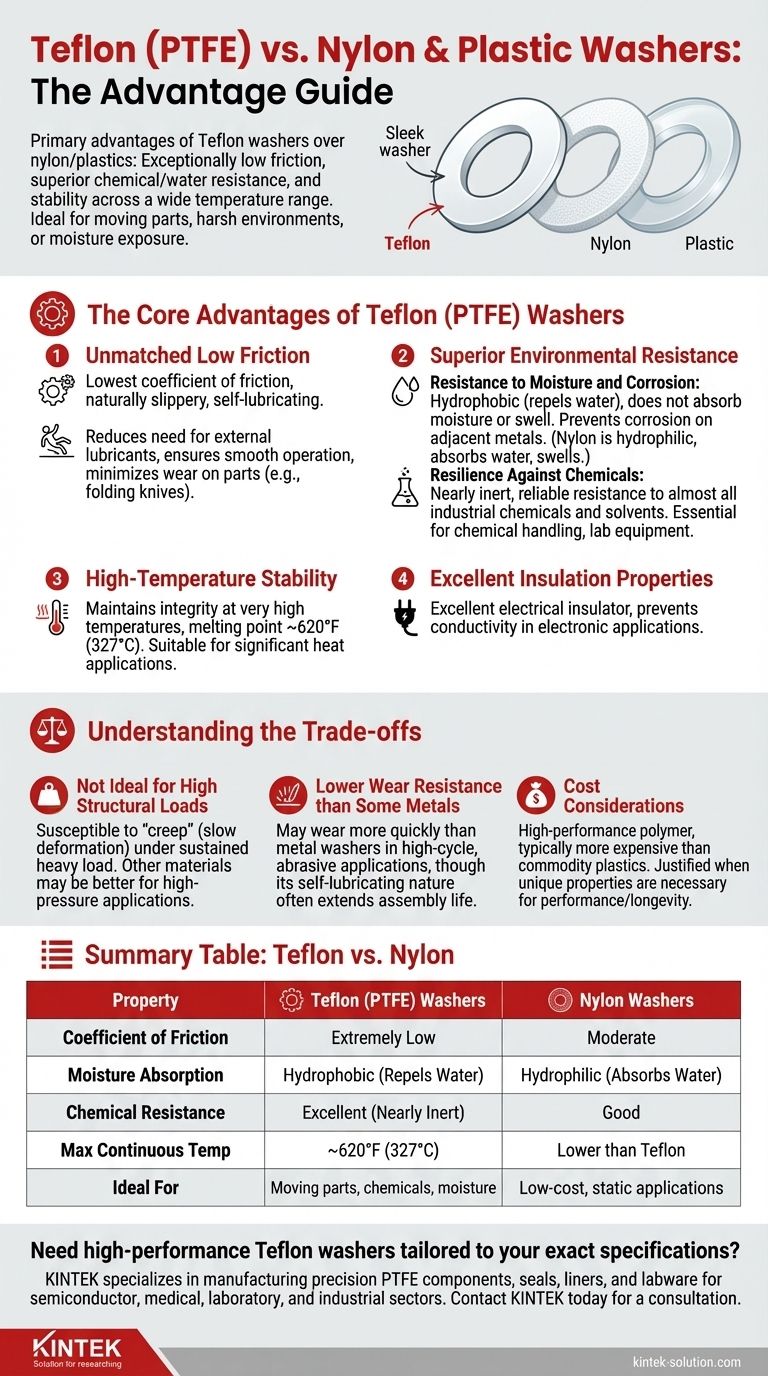

The Core Advantages of Teflon (PTFE) Washers

Teflon, or Polytetrafluoroethylene (PTFE), has a unique combination of properties that sets it apart from nearly all other plastics, including nylon.

Unmatched Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, making it naturally "slippery."

This self-lubricating quality is a significant advantage, as it reduces the need for external lubricants, ensures smooth operation, and minimizes wear on adjacent metal surfaces.

This is why Teflon washers are frequently used in mechanisms with pivoting parts, like folding knives, where consistent, smooth action is required even without regular maintenance.

Superior Environmental Resistance

Teflon is exceptionally resilient when exposed to moisture and a wide array of chemicals, environments where other plastics can quickly fail.

Resistance to Moisture and Corrosion

A key differentiator is that Teflon is hydrophobic, meaning it repels water. It will not absorb moisture or swell in humid conditions.

This stability is critical for maintaining tight tolerances and preventing the washer from promoting corrosion on adjacent metal parts. In contrast, nylon is hydrophilic and absorbs moisture, which can cause it to swell and lose dimensional stability.

Resilience Against Chemicals

Teflon washers are nearly inert and demonstrate reliable resistance against almost all industrial chemicals and solvents.

This makes them essential components in chemical handling systems, laboratory equipment, and industrial machinery where exposure to corrosive substances is common.

High-Temperature Stability

Teflon maintains its integrity at very high temperatures, with a melting point of around 620°F (327°C).

This allows Teflon washers to be used in applications involving significant heat where commodity plastics like standard nylon would deform or melt.

Excellent Insulation Properties

In addition to its other benefits, Teflon is an excellent electrical insulator, making it a reliable choice for electronic and electrical applications where preventing conductivity is necessary.

Understanding the Trade-offs

While Teflon's advantages are significant, no material is perfect for every situation. Understanding its limitations is key to making an informed decision.

Not Ideal for High Structural Loads

While durable and abrasion-resistant, pure Teflon can be susceptible to "creep" — a slow deformation under sustained, heavy mechanical load.

For high-pressure structural applications, other materials or filled grades of Teflon may be more suitable.

Lower Wear Resistance than Some Metals

Although Teflon causes less wear on surrounding parts, it may wear more quickly than a metal washer (like phosphor bronze) in certain high-cycle, abrasive applications.

However, its self-lubricating nature often extends the life of the entire assembly, making this a worthwhile trade-off.

Cost Considerations

Teflon is a high-performance polymer, and it is typically more expensive than commodity plastics like standard nylon.

Its selection is justified when its unique properties are necessary for the performance and longevity of the application.

Making the Right Choice for Your Application

To select the correct washer, focus on the primary demands of your project's environment and performance requirements.

- If your primary focus is smooth, low-maintenance mechanical movement: Choose Teflon for its unmatched self-lubricating properties.

- If your primary focus is performance in a wet or humid environment: Choose Teflon because its hydrophobic nature prevents swelling and corrosion.

- If your primary focus is resilience against chemicals or high temperatures: Choose Teflon for its superior chemical and thermal resistance.

- If your primary focus is a simple, low-cost static application with no harsh exposures: Nylon or another standard plastic may be sufficient.

By aligning the material's inherent strengths with your application's needs, you can ensure reliable and long-lasting performance.

Summary Table:

| Property | Teflon (PTFE) Washers | Nylon Washers |

|---|---|---|

| Coefficient of Friction | Extremely Low | Moderate |

| Moisture Absorption | Hydrophobic (Repels Water) | Hydrophilic (Absorbs Water) |

| Chemical Resistance | Excellent (Nearly Inert) | Good |

| Max Continuous Temp | ~620°F (327°C) | Lower than Teflon |

| Ideal For | Moving parts, chemicals, moisture | Low-cost, static applications |

Need high-performance Teflon washers tailored to your exact specifications?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the superior chemical resistance, low friction, and thermal stability your application demands.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing a perfect fit and optimal performance.

Contact KINTEK today for a consultation and let our experts provide a solution that enhances your product's reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes PTFE a common choice for rotary shaft applications? Unlock Superior Performance & Reliability

- What are the advantages of Teflon washers? Achieve Superior Performance in Harsh Environments

- What aerospace applications utilize PTFE seals? Ensure Reliability in Extreme Conditions

- Why are PTFE rotary shaft lip seals ideal for chemical processing plants? Ensure Reliability in Corrosive Environments

- What are the installation benefits of expanded PTFE gaskets? Achieve Reliable Seals on Imperfect Flanges

- What are the key advantages of choosing Teflon bearings for applications? Solve Extreme Environment Challenges

- What are the advantages of Teflon encapsulated o-rings? Superior Chemical & Temperature Resistance

- What advantages do ePTFE gaskets have over conventional rubber and plastic seals? Superior Performance in Extreme Environments